Novel high-speed railway power bearing

A high-speed, high-speed rail technology, applied in rolling contact bearings, rotating bearings, bearings, etc., can solve problems such as peeling, poor high-speed performance, and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

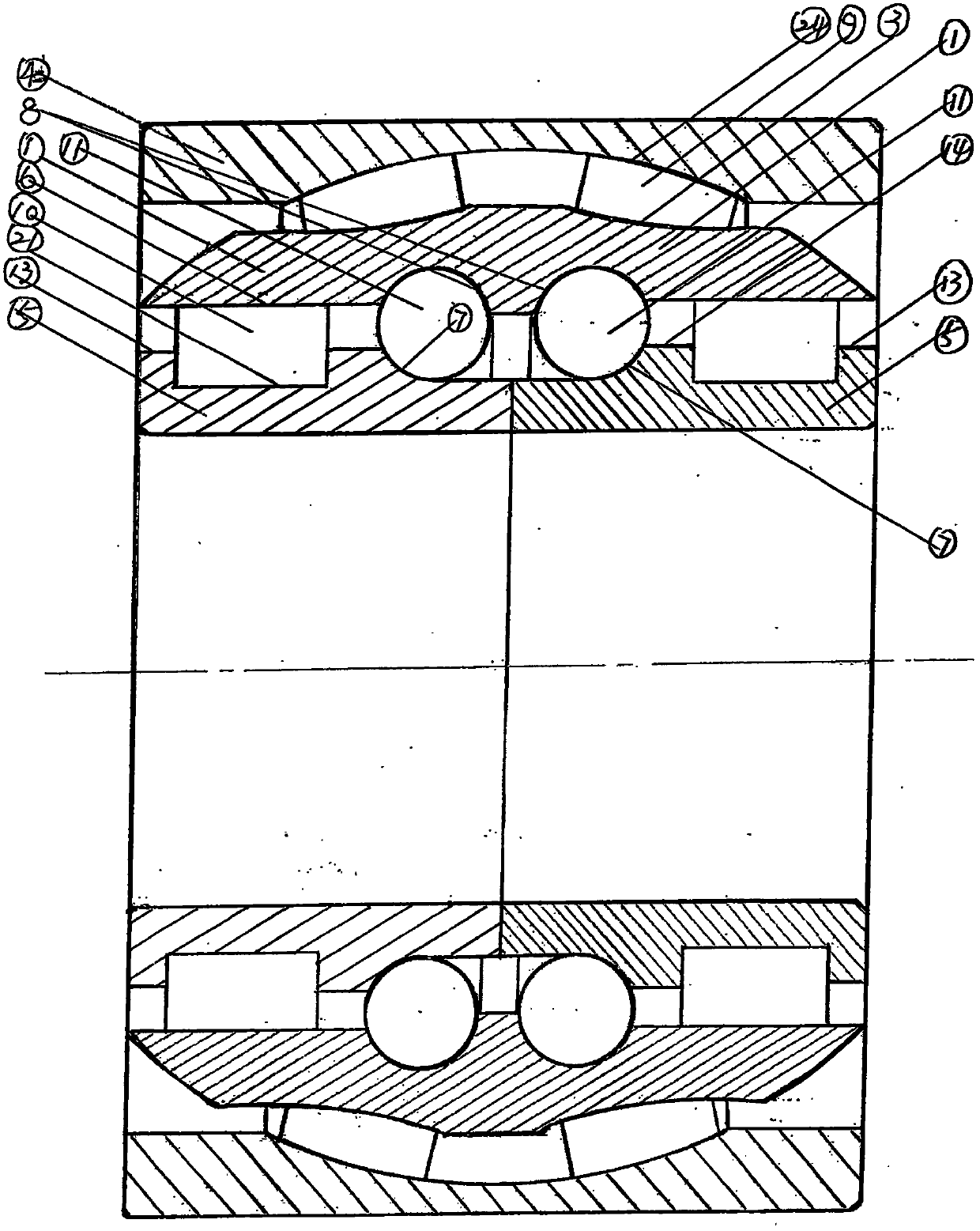

Embodiment 1

[0067] Such as figure 1 The "new high-speed high-speed rail dynamic bearing" shown includes: a variable-diameter middle ring 1, an outer ring 4, two double-half inner rings 5, and inner and outer two-layer rolling elements; the variable-diameter middle ring 1 is axially In the middle of the distance, there are two rings of double-row angular contact spherical rolling body tracks 8, and a row of spherical roller tracks 3 are respectively provided at the two ends of the outer circumference corresponding to the distance, forming a variable-diameter middle ring structure. 1 Spherical rolling elements 11 are arranged in the two double-row angular contact ball rolling element tracks 8 of the inner circumference, and a row of cylindrical roller tracks are respectively arranged at the two ends of the double row angular contact spherical rolling element track 8 corresponding to the distance between them. 6. Cylindrical rollers 10 are set in the track, and spherical rollers 9 are respe...

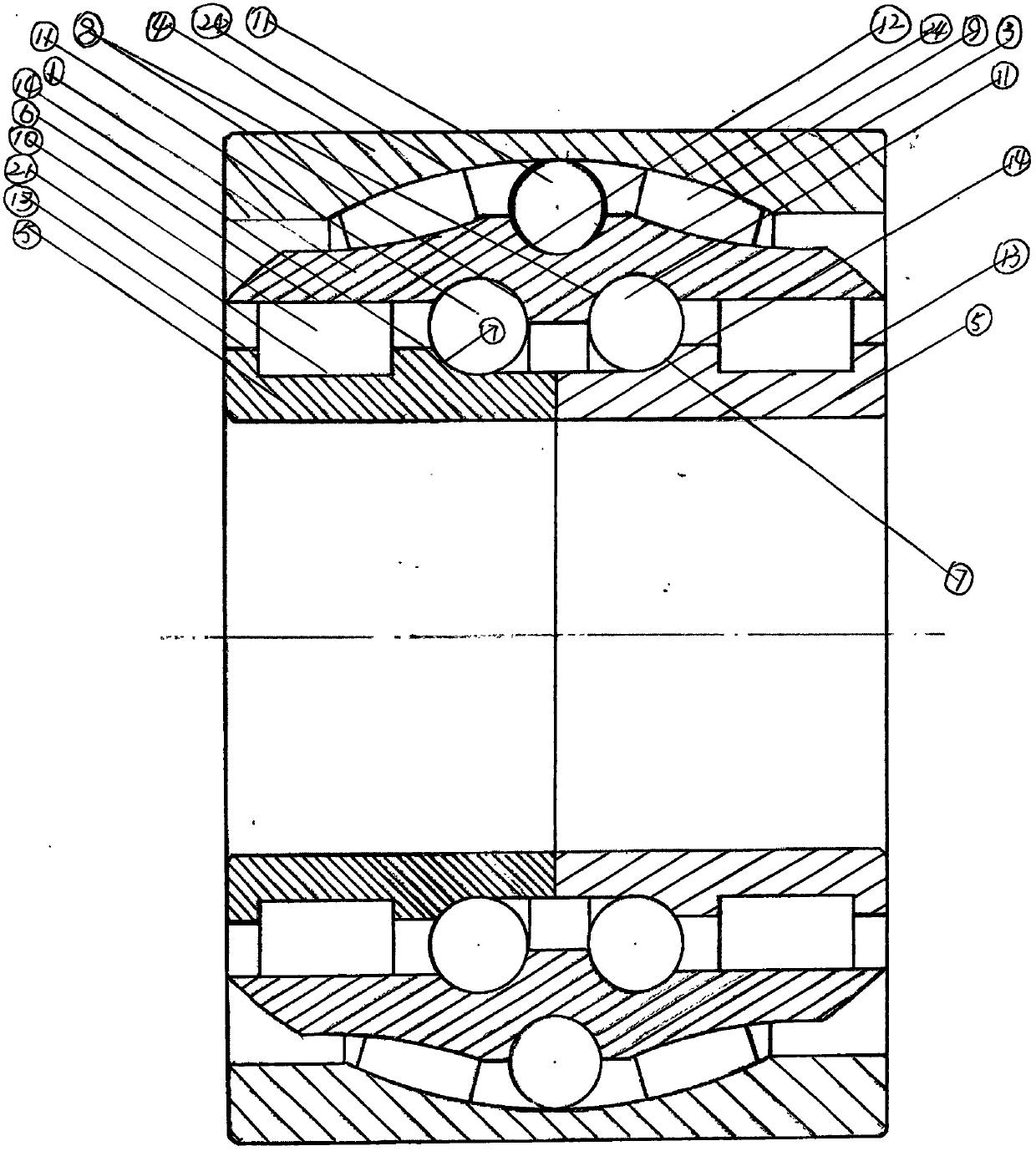

Embodiment 2

[0071] Such as figure 2 The "new high-speed high-speed rail dynamic bearing" shown includes: a variable-diameter middle ring 1, an outer ring 4, double-half inner rings 5, and inner and outer two-layer rolling elements; the axial distance of the variable-diameter middle ring 1 inner circumference There are two rings of double-row angular contact spherical rolling body tracks 8 in the middle, and a circle of deep groove spherical rolling body tracks 12 in the middle of its outer circumference. There is a corresponding distance between the two ends of the deep groove spherical rolling body tracks 12. The roller track 3 of the volleyball surface forms a variable-diameter middle ring structure, and a spherical rolling body 11 is arranged in the deep-groove ball rolling body track 12 provided in the middle of the outer circumference of the variable-diameter middle ring 1, and spherical rolling bodies 11 are arranged in its spherical roller track 3. The rollers 9 are provided with ...

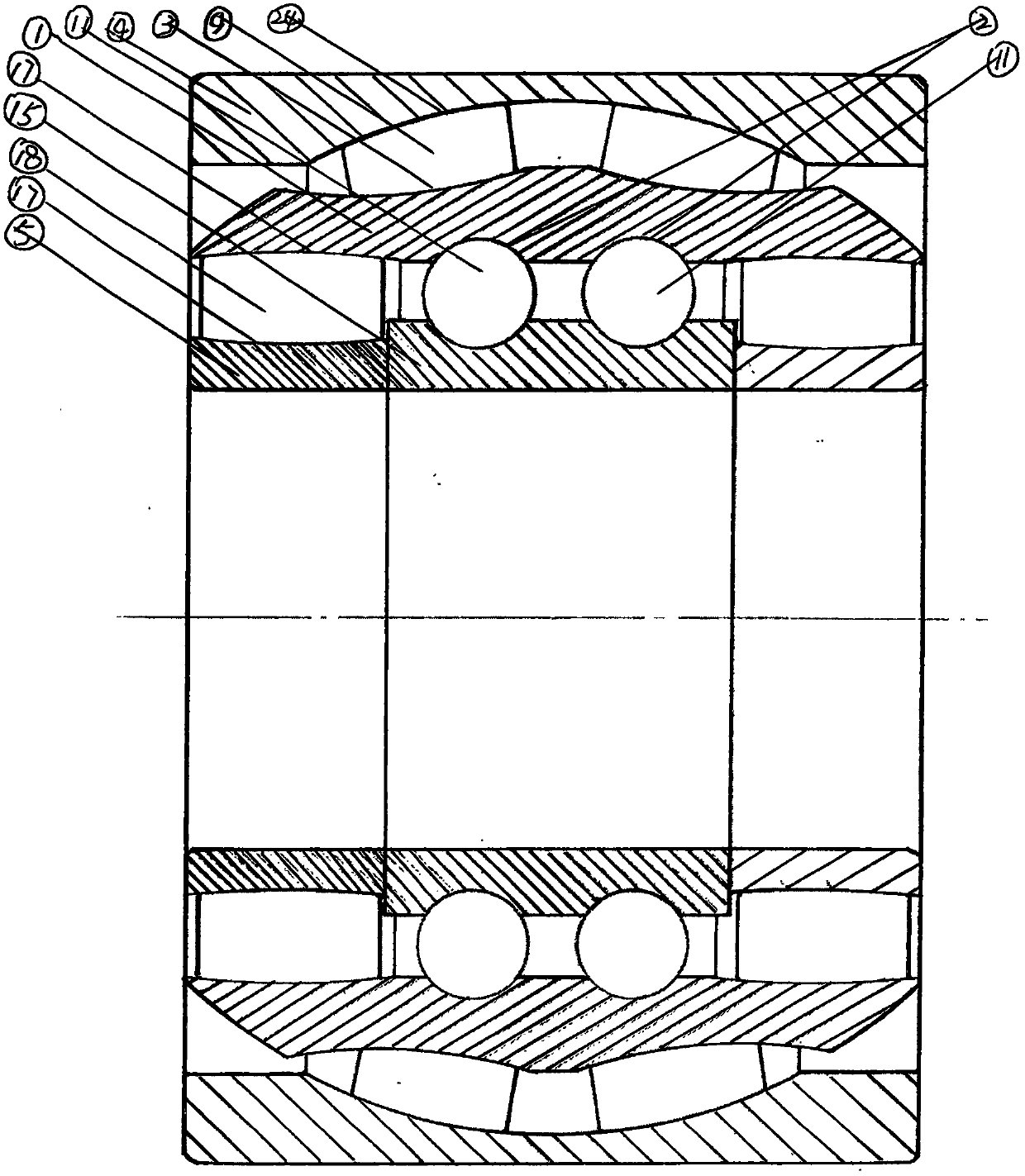

Embodiment 3

[0075] Such as image 3 The "new high-speed high-speed rail dynamic bearing" shown includes: a variable-diameter middle ring 1, an outer ring 4, a double-row deep groove ball bearing inner ring 15, a double-half inner ring 5, and inner and outer two-layer rolling elements ; The variable-diameter middle ring 1 is provided with two rings of double-row deep-groove spherical rolling element tracks 2 in the middle of the axial distance of the inner circumference, and a row of spherical roller tracks 3 are respectively provided at the two ends of the outer circumference corresponding to the distance between them, forming In the variable-diameter middle ring structure, spherical rolling elements 11 are respectively arranged in the double-row deep-groove ball rolling-element track 2 on the inner circumference of the variable-diameter middle ring 1, and the distance between the two ends of the double-row deep-groove spherical rolling element track 2 is the same Correspondingly, a row o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com