Matching performance verification method of a ferrule joint and an instrument pipe for a nuclear power station

A ferrule joint and matching performance technology, which is applied in the direction of using liquid/vacuum to measure liquid tightness, using stable tension/pressure to test material strength, instruments, etc. Problems such as similar working conditions and no test methods have been achieved to achieve localization, which is conducive to product improvement and quality supervision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

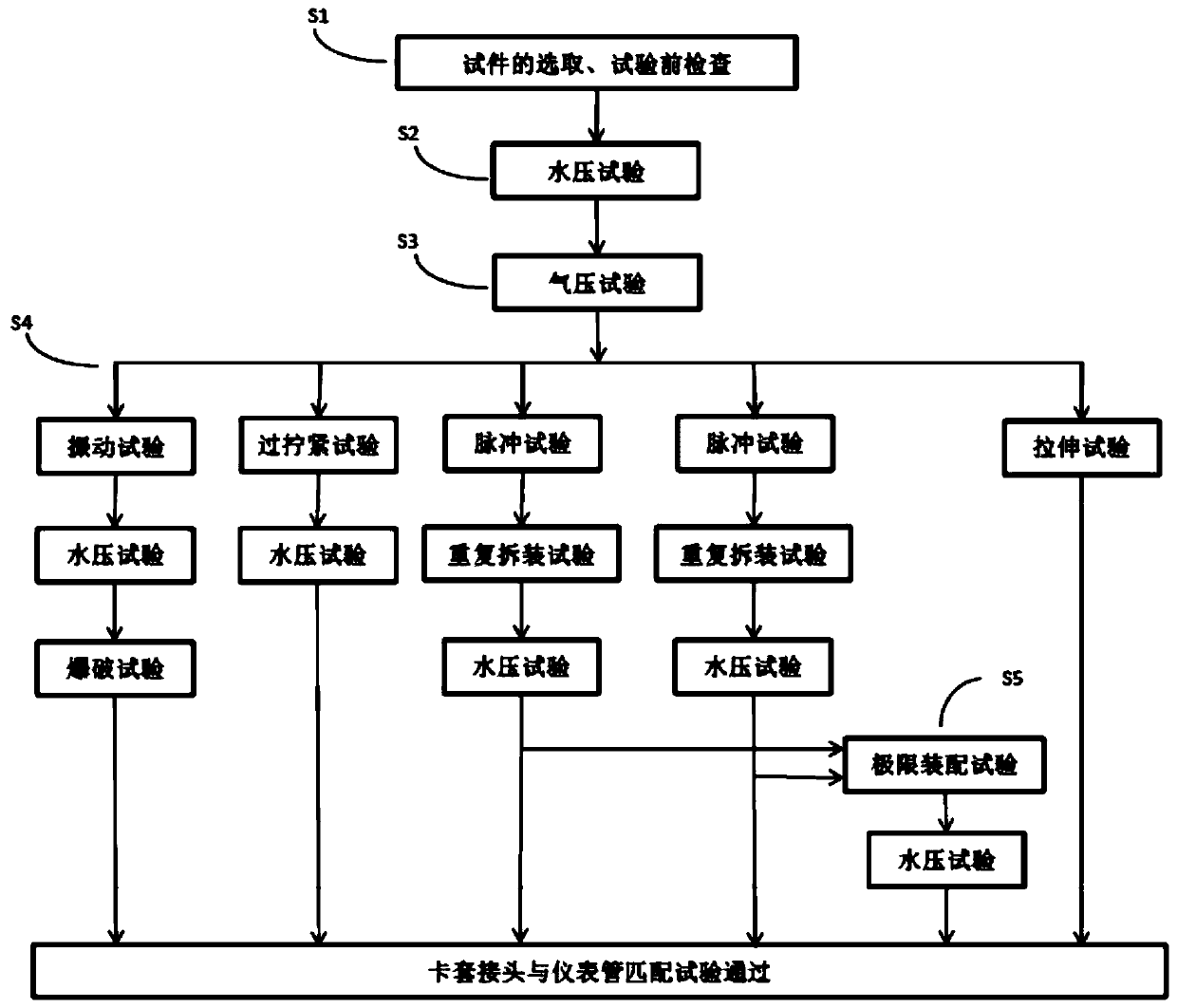

[0038] The invention provides a method for verifying the matching performance of ferrule joints and instrument pipes used in nuclear power plants, which is used to test the matching performance of ferrule joints used in nuclear power plants and instrument pipes used in nuclear power plants, including the following steps:

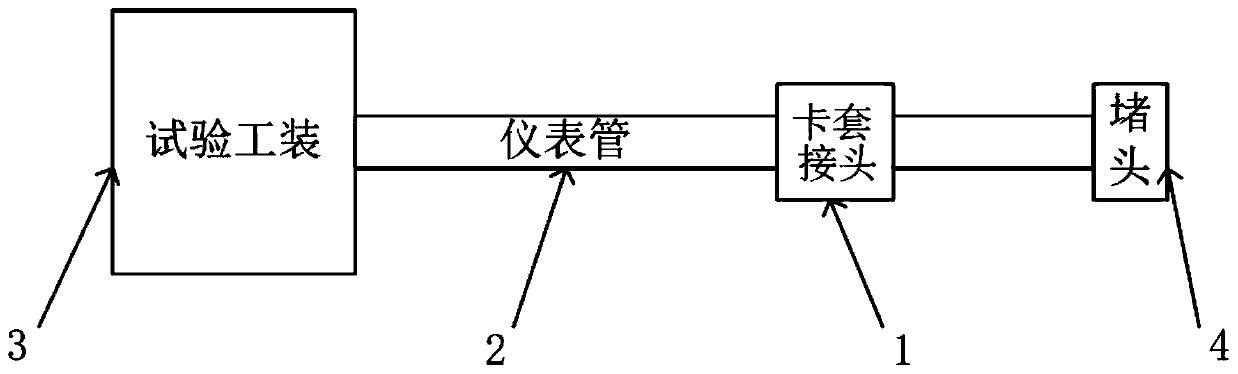

[0039] Step S1, select ferrule joints with uniform caliber specifications and instrument tubes with uniform caliber specifications from a certain batch of ferrule joints and instrument tubes to form M groups of test pieces, M≥3, and each set of test pieces shall not be less than 5 test pieces. (you can do more, the more you do, the more representative), named as the first test piece, the second test piece, the third test piece, the fourth test piece, the fifth test piece, each test piece consists of a The ferrule joint is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com