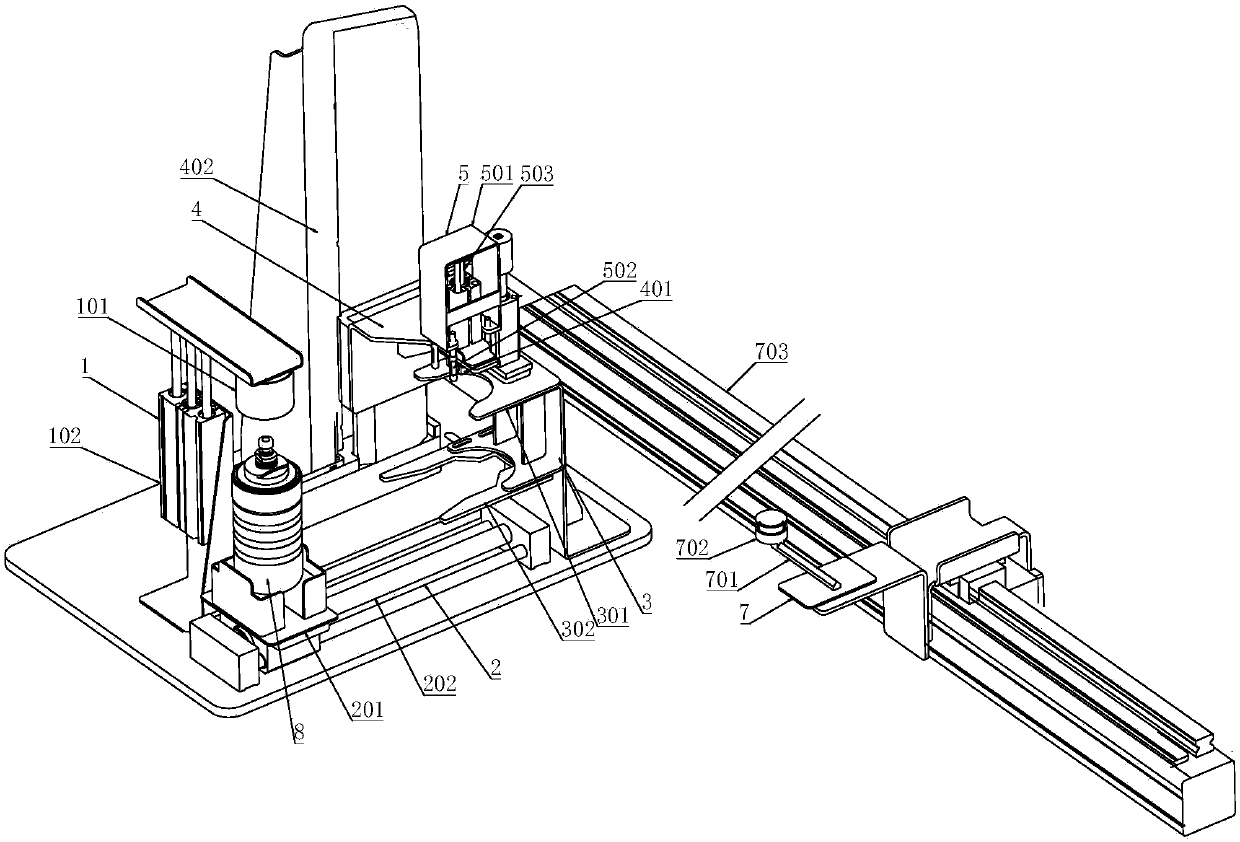

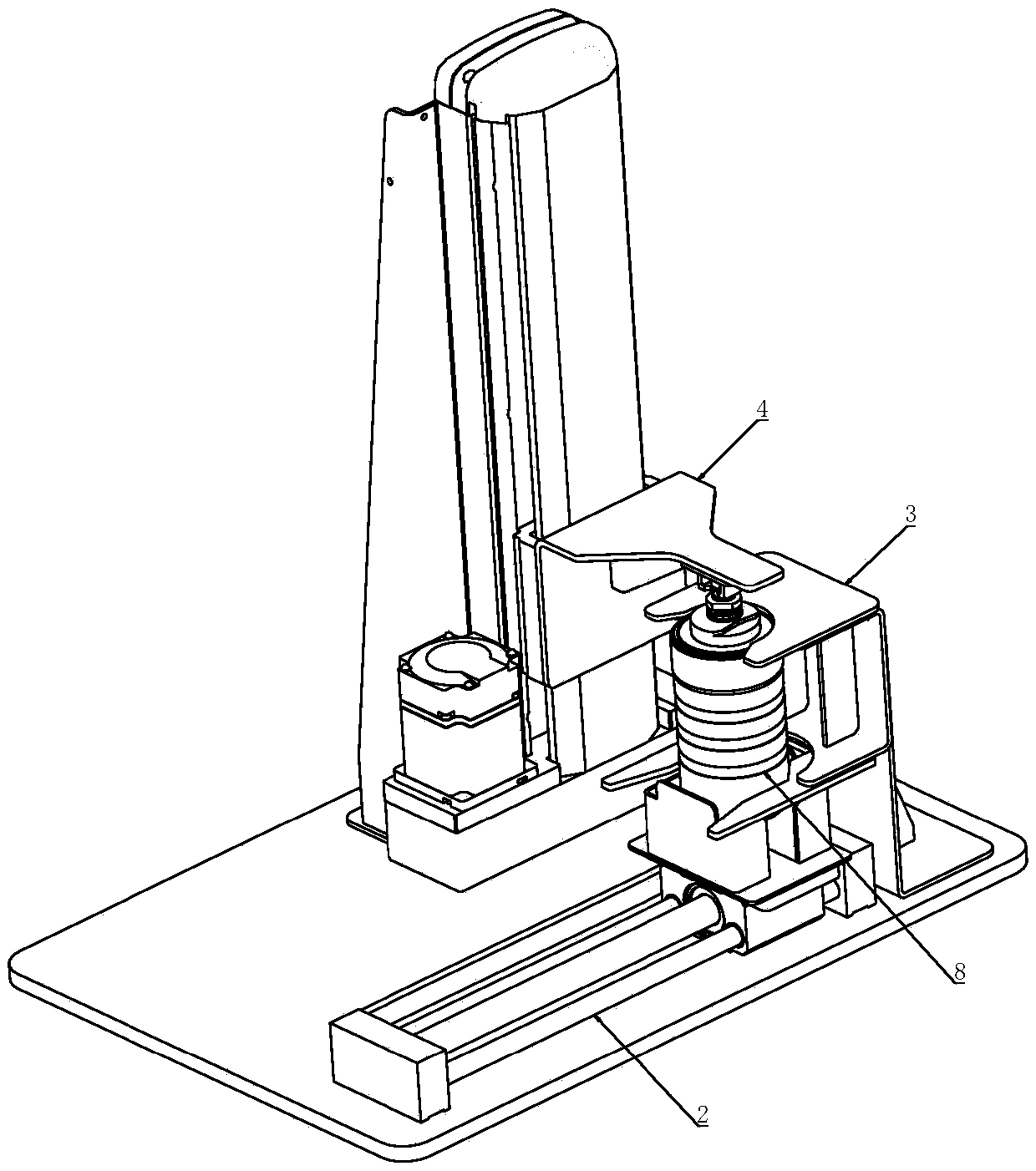

System and method for taking and placing crucible in oxygen bomb

An inner crucible and oxygen bomb technology, applied in the field of sample testing, can solve the problems of complicated operation and low efficiency, and achieve the effect of simple overall structure, convenient accurate positioning and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

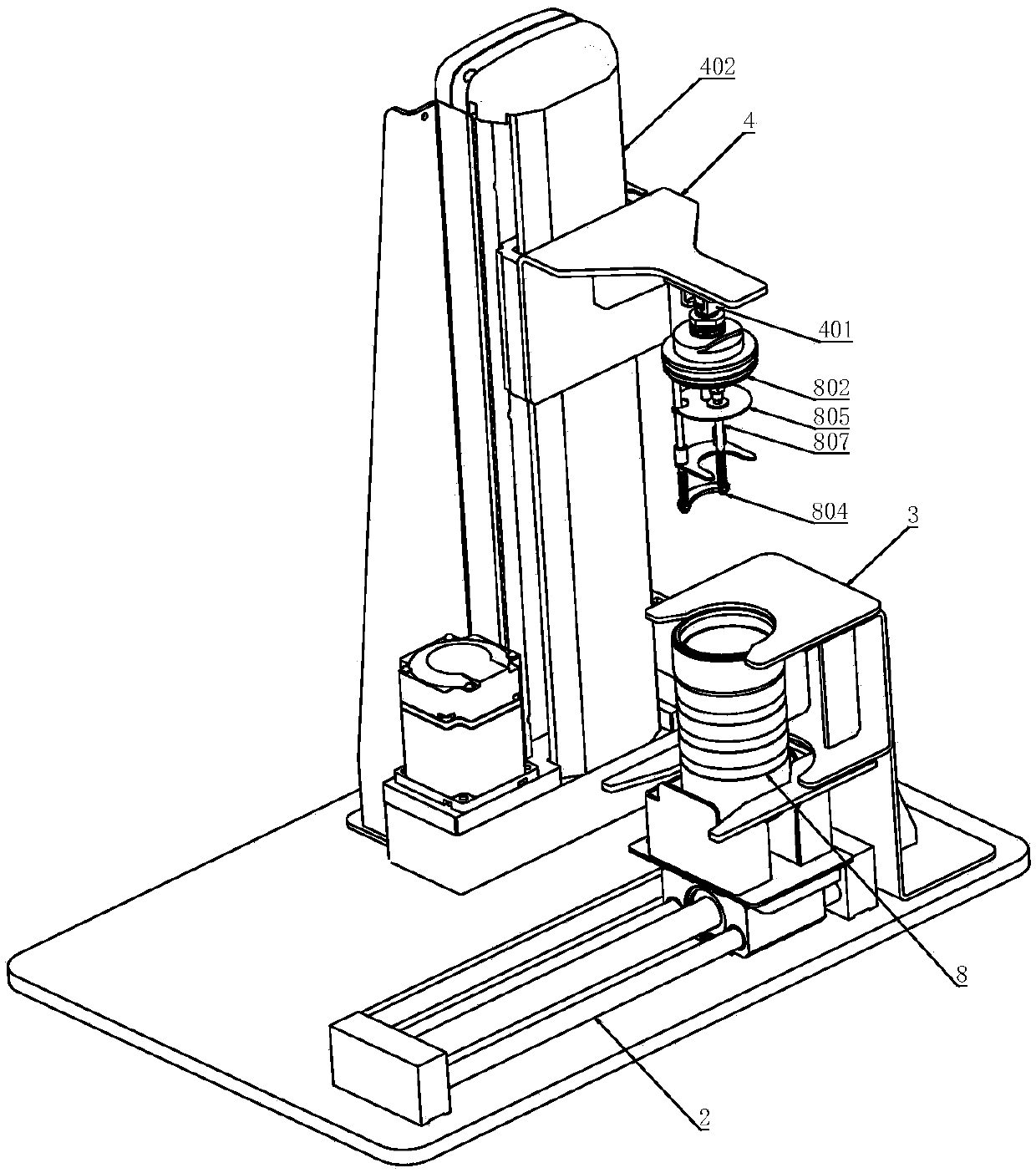

[0053] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0054] Such as Figure 4As shown, the oxygen bomb 8 aimed at by the crucible pick-and-place system in the oxygen bomb of the present invention includes: comprising an oxygen bomb body 801, an oxygen bomb core 802 and an oxygen bomb cover, one end opening of the oxygen bomb body 801, the oxygen bomb cover and the oxygen bomb cover The opening of the body 801 is sealed and detachably connected to fix the oxygen bomb core 802 in the oxygen bomb body 801. A crucible support bracket 804 is hung on the oxygen bomb core 802, and a crucible support 805 is installed on the crucible support bracket 804. An ignition rod 807 is installed on the bullet core 802, wherein the crucible holder 805 is provided with two sets of parts, which are respectively set on the two poles of the crucible support bracket 804, and can slide up and down along the poles. A spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com