A kind of biomass fuel baking furnace

A biomass fuel and baking oven technology, which is applied in the direction of roasters/barbecue grids, kitchen utensils, household utensils, etc., can solve the problems of affecting the heat conduction of the baking box and affecting the baking effect of food in the baking box, so as to improve the baking effect, Simple structure, easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

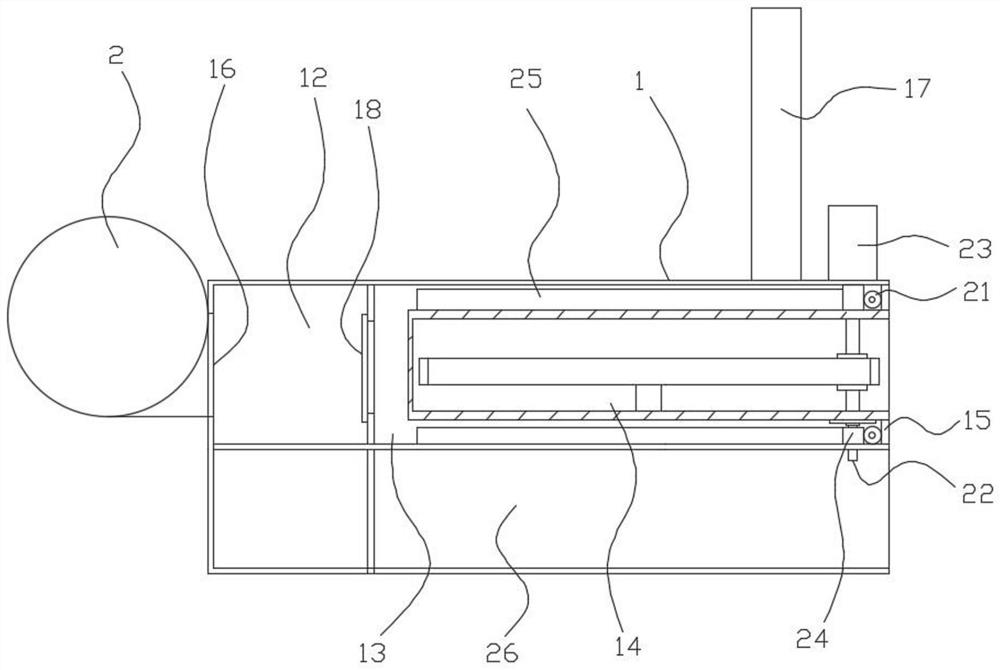

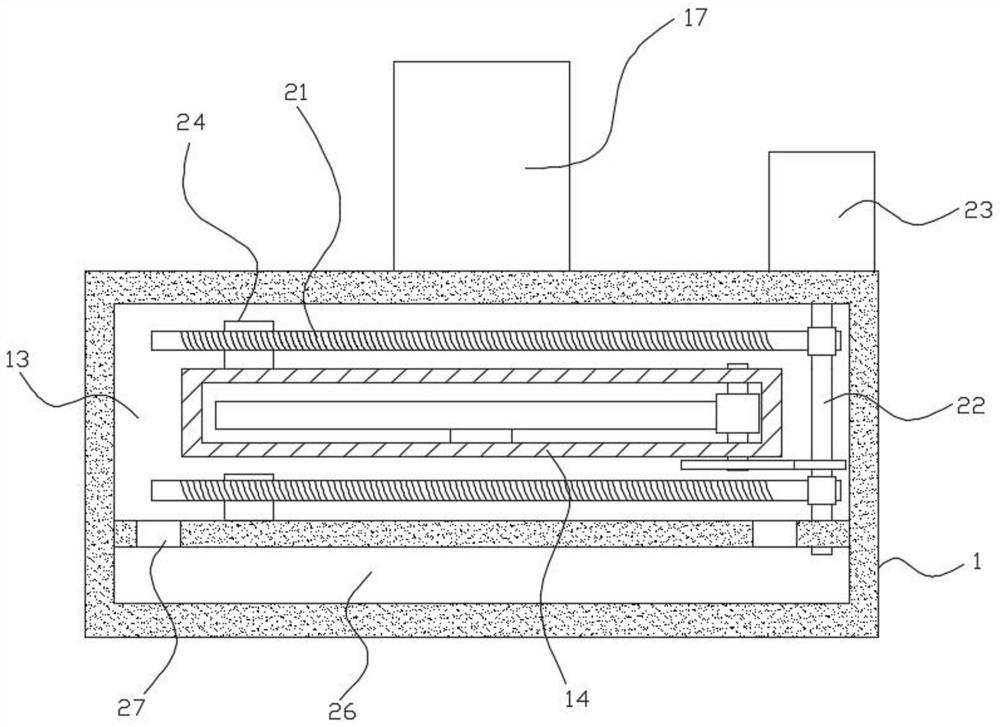

[0023] Such as figure 1 , figure 2 Shown; A kind of biomass fuel roaster, comprises:

[0024] Furnace body 1, a combustion chamber 12 and a baking chamber 13 are arranged in the furnace body 1, and a baking box 14 is arranged in the baking room 13. The upper and lower sides of the baking box 14 and the inner side walls of the baking chamber 13 are respectively supported by support plates 15, and the support plates pass through The bolts are fixedly installed in the baking chamber, which is convenient to disassemble the support. There is a gap between the two sides of the baking box 14 and the inner wall of the baking chamber 13. The combustion chamber 12 and the baking chamber 13 are provided with a filter screen 18. Air inlet 16, a chimney 17 is arranged on the upper part of the baking chamber 13;

[0025] The blower 2, the air outlet of the blower 2 communicates with the air inlet 16;

[0026] The upper and lower support plates 15 of the baking box 14 are respectively eq...

Embodiment 2

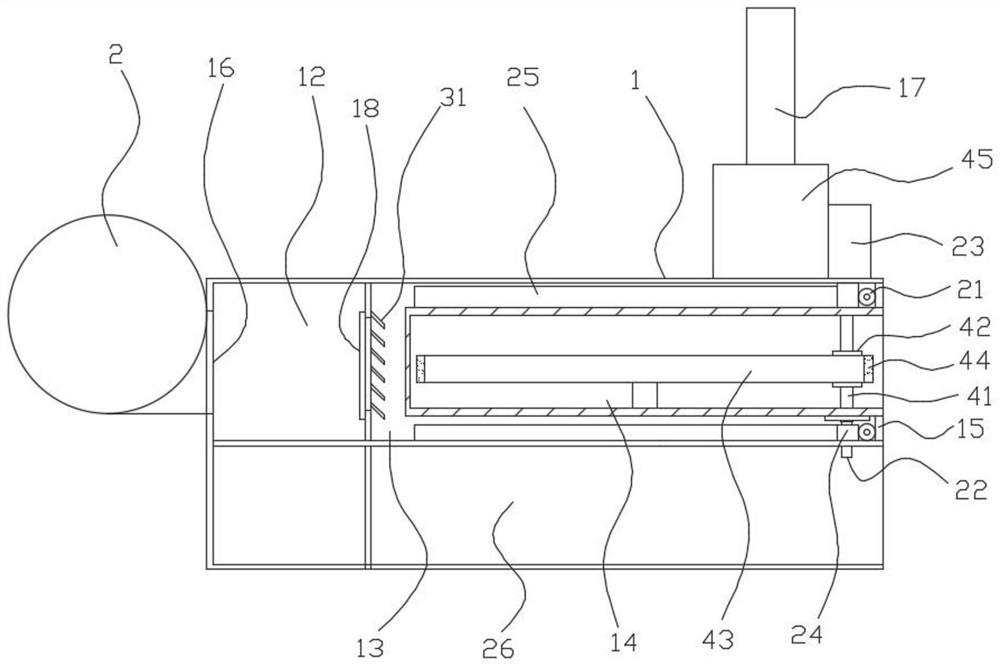

[0030] Such as image 3 , Figure 4 Shown; A kind of biomass fuel roaster, comprises:

[0031] Furnace body 1, a combustion chamber 12 and a baking chamber 13 are arranged in the furnace body 1, and a baking box 14 is arranged in the baking room 13. The upper and lower sides of the baking box 14 and the inner side walls of the baking chamber 13 are respectively supported by support plates 15, and the support plates pass through The bolts are fixedly installed in the baking chamber, which is convenient to disassemble the support. There is a gap between the two sides of the baking box 14 and the inner wall of the baking chamber 13. The combustion chamber 12 and the baking chamber 13 are provided with a filter screen 18. Air inlet 16, a chimney 17 is arranged on the upper part of the baking chamber 13;

[0032] The blower 2, the air outlet of the blower 2 communicates with the air inlet 16;

[0033] The upper and lower support plates 15 of the baking box 14 are respectively eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com