Gasification combustion furnace with low-temperature desaccharification

A combustion furnace and sugar removal technology, applied in the field of boilers, can solve the problems affecting the heating and heat transfer of the boiler, reduce the service life of the boiler, and cannot be removed, and achieve the effects of secondary utilization, cost saving, and reduction of the probability of blasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

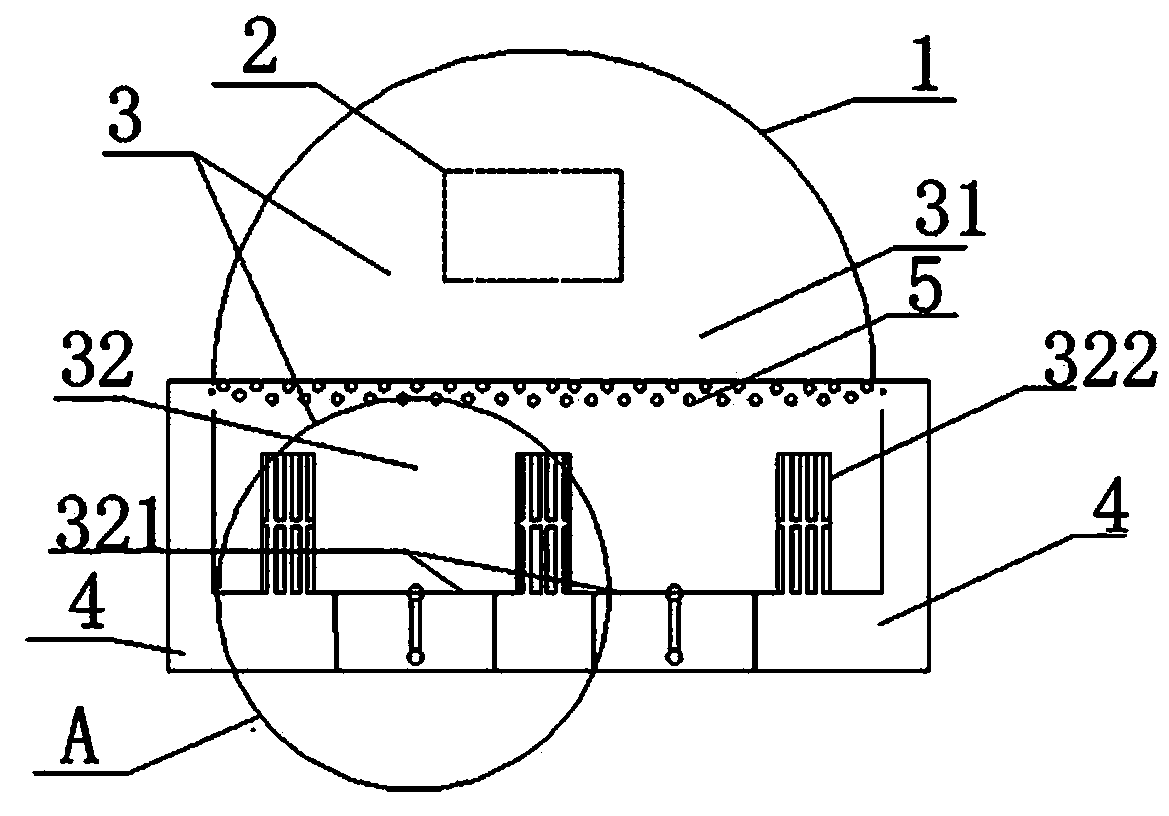

[0041] Such as figure 1 , Figure 4 The shown low-temperature desugar combustion furnace includes two parts: a furnace body 1 and an induced draft fan 2. Preferably, an explosion-proof nozzle 1c is provided outside the furnace body 1, and the explosion-proof nozzle 1c has the function of adjusting the pressure in the furnace. When deflagration occurs inside the furnace body 1 , when the pressure inside the furnace body 1 rises rapidly, the explosion-proof nozzle 1c automatically releases the pressure in the furnace to prevent the furnace body 1 from exploding due to the deflagration pressure. Port 1a communicates with combustion zone 2 32. The opening direction of feed port 1a is preferably between 0-90° to the vertical direction. Feed port 1a is convenient for putting straw fuel into furnace body 1. The outer side of the bottom of the furnace body communicates with the waste material chamber 6, and a flat furnace door can be selected to facilitate cleaning out the burned was...

Embodiment 2

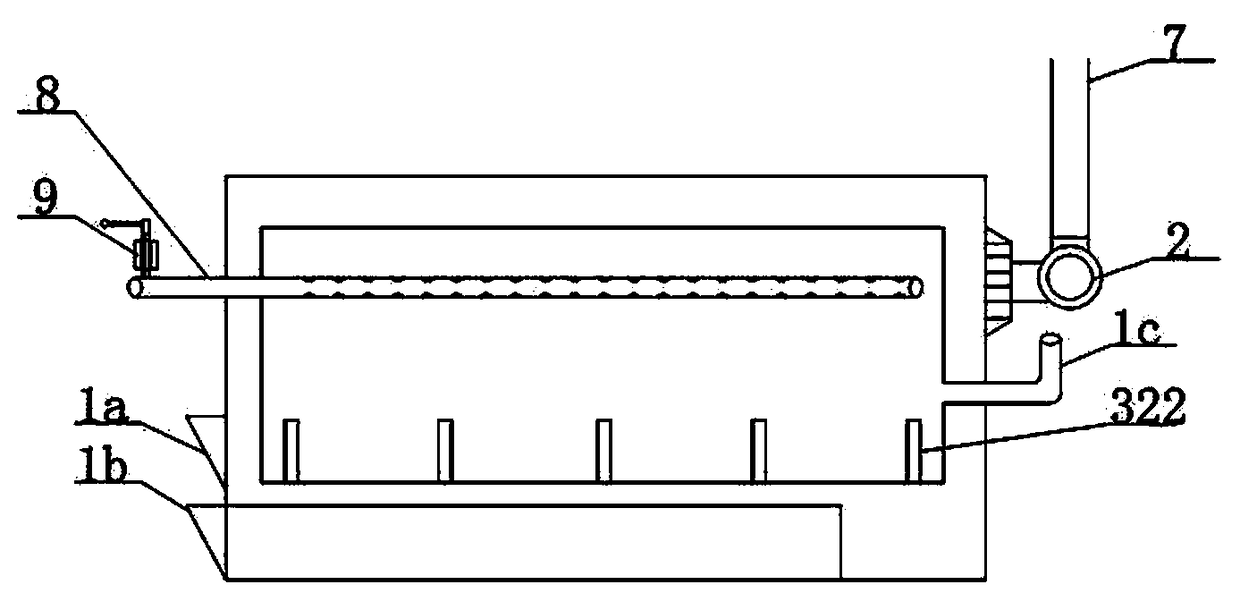

[0060] Such as figure 2 As shown in , the technical solution of this embodiment can refer to the technical solution of embodiment 1, and the body of furnace structure in this embodiment can also refer to the body of furnace structure in embodiment one, but the structure of body of furnace 1 in the present embodiment and implementation The difference of body of furnace 1 structure in example one is: as figure 2 The low-temperature desugaring combustion furnace shown also includes: air duct three 8 and air valve 9, air duct three 8 is inserted on furnace body 1, and communicates combustion zone one 31 with the atmosphere outside furnace body 1, air duct three 8 is located at The part in the combustion zone-31 can choose flower tube structure, open the through hole near the position of gas injection hole 5, the number of through holes can be multiple, it is arranged in this way while increasing the ventilation rate, it also helps to disperse and evenly supply the air. To preve...

Embodiment 3

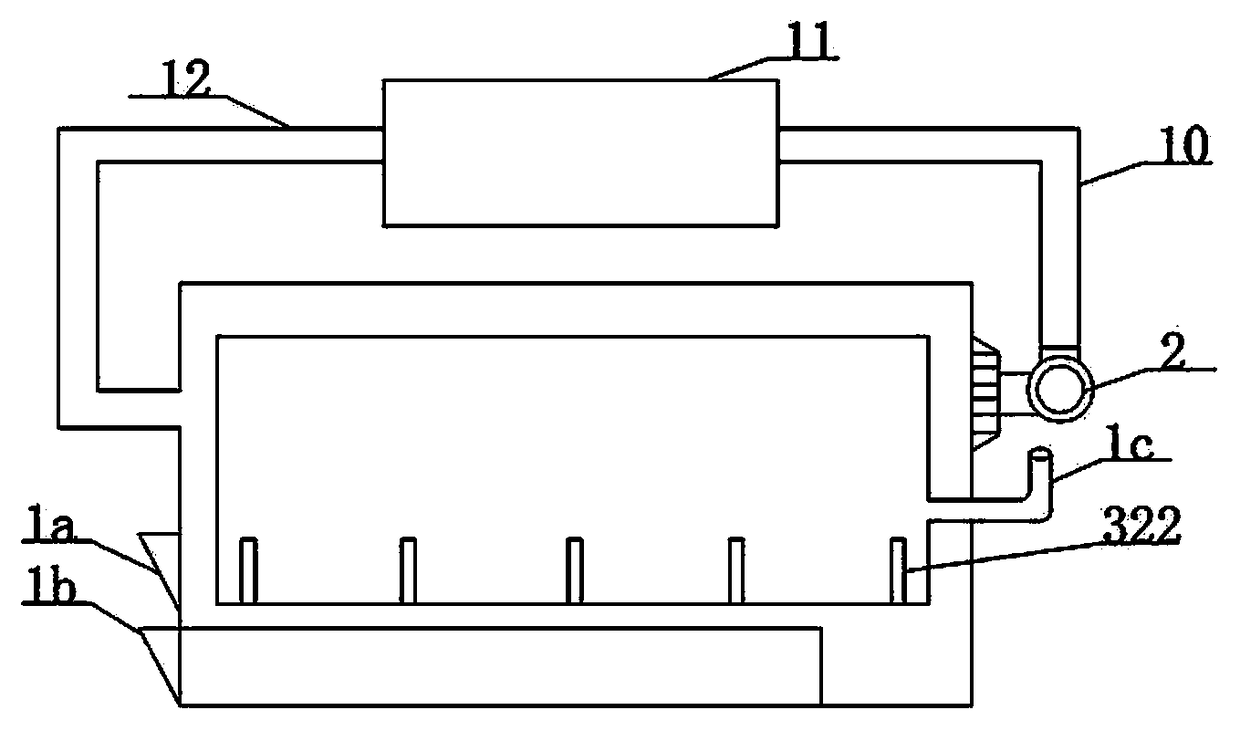

[0075] Such as image 3 As shown in , the technical solution of this embodiment can refer to the technical solution of embodiment 1, and the body of furnace structure in this embodiment can also refer to the body of furnace structure in embodiment one, but the structure of body of furnace 1 in the present embodiment and implementation The difference of body of furnace 1 structure in example one is: as image 3 As shown in the low-temperature desugar combustion furnace, there are flue one 7, smoke box 8, and flue two 9 outside the furnace body 1. The air inlet of the induced draft fan 2 is connected to the air duct one 3 in the furnace body 1, and the air outlet is connected to the flue one. 7 is connected, flue one 7, flue two 9 one end is communicated with air duct one 3 in body of heater 1, and the other end connects smoke box. The smoke box 8 is located outside the furnace body 1, and communicates with the first flue 7 and the second flue 9. The air duct one 4, the induce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com