Integral complete denture digital manufacturing system and method

A technology for complete dentures and manufacturing methods, applied in the direction of dental prosthesis, additive manufacturing, manufacturing tools, etc., can solve problems such as displacement errors, complete dentures falling off, and insufficient strength, so as to improve production efficiency, shorten time, and realize The effect of digital processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

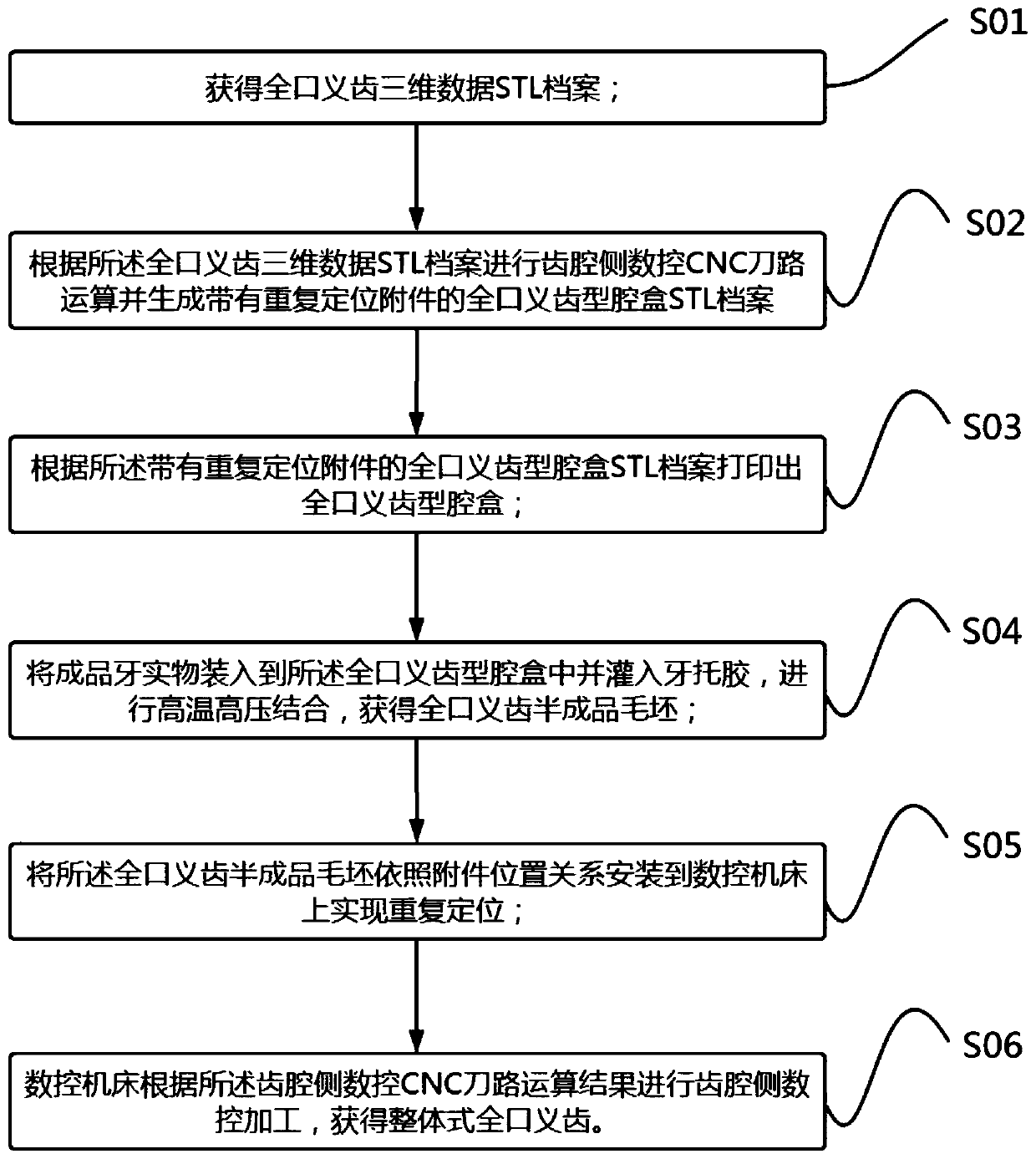

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

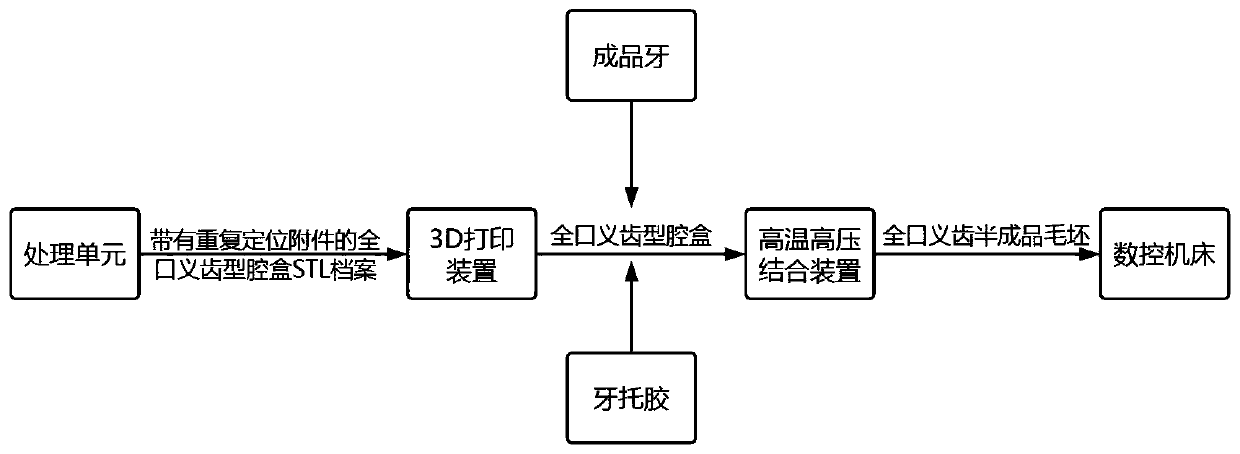

[0053] refer to figure 1 , is an integral complete denture digital production system disclosed by the present invention, comprising:

[0054] Processing unit: used to obtain the STL file of the three-dimensional data of the complete denture, perform the numerical control CNC toolpath calculation on the tooth cavity side according to the STL file of the three-dimensional data of the complete denture, and generate the STL file of the cavity box of the complete denture with repeated positioning accessories;

[0055] 3D printing device: used to print out the full denture cavity box according to the STL file of the full denture cavity box with repeat positioning accessories;

[0056] High-temperature and high-pressure bonding device: used for high-temperature and high-pressure bonding of the finished tooth corresponding to the established finished tooth database ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com