Steel strip cleaning machine

A washing machine and steel belt technology, applied in the direction of dryers, progressive dryers, cleaning methods and appliances, etc., can solve the problems of huge equipment combination and inconvenient winding, and achieve short process time and small footprint , The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

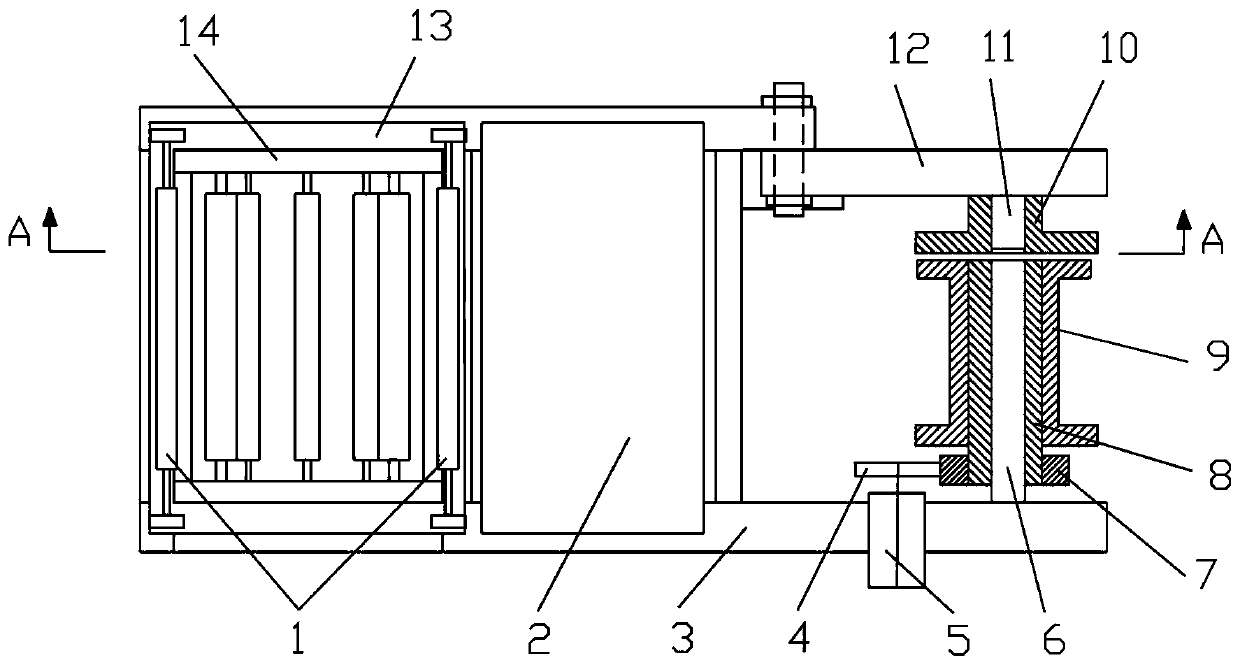

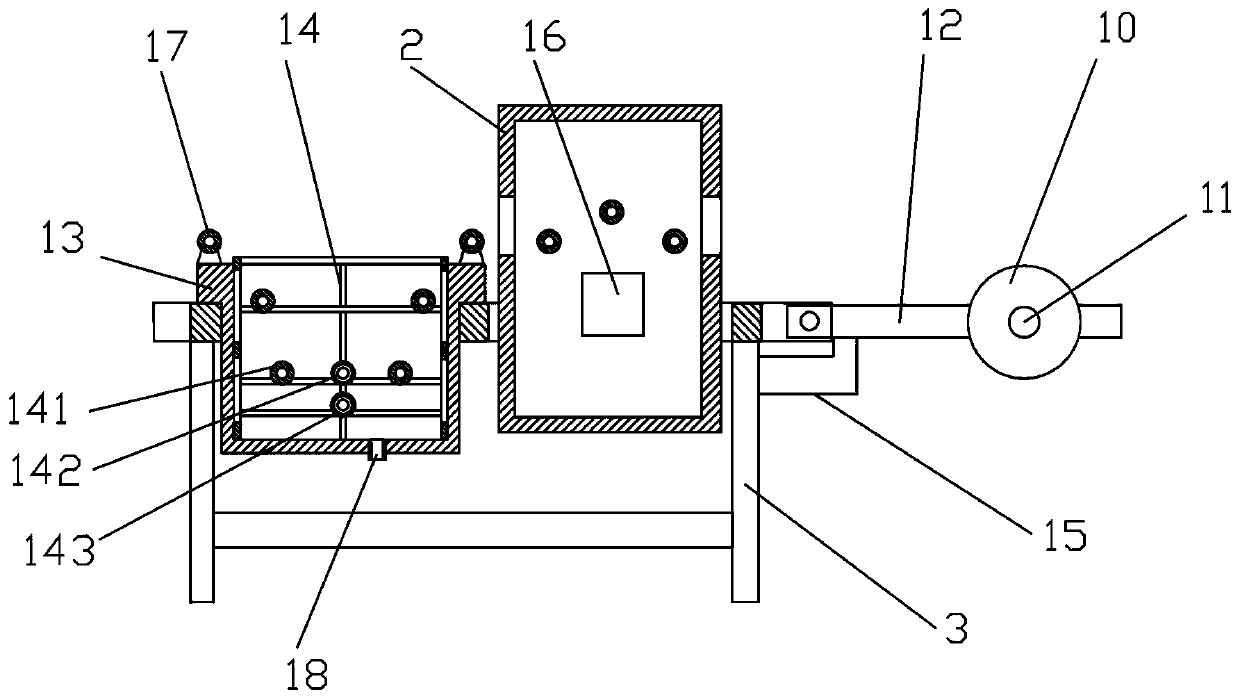

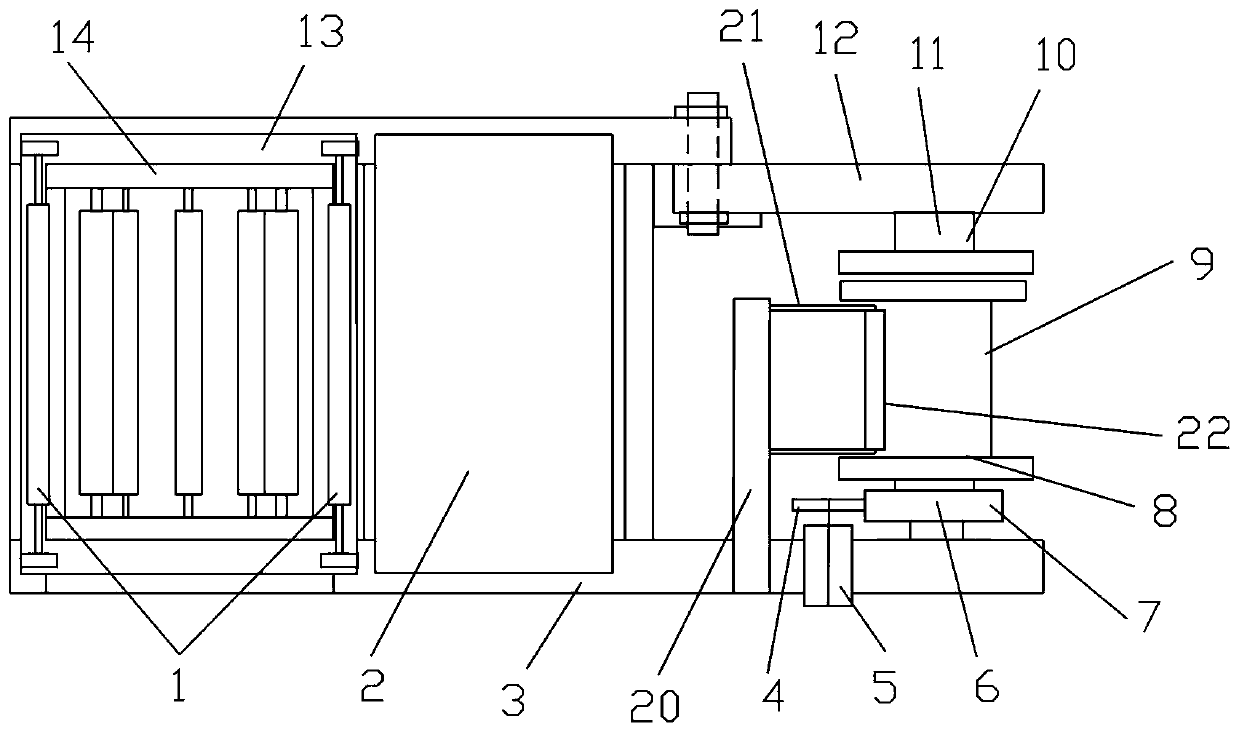

[0029] Embodiment one, refer to figure 1 and figure 2 , the steel strip cleaning machine comprises a base 3, a cleaning tank 13 and a drying box 2 are fixed on the base 3, the cleaning tank 13 is fixed on the left side of the base 3, and the drying box 2 is fixed on the right side of the cleaning tank 13 On the base 3, wherein, the base 3 is a frame body composed of rods, the cleaning tank 13 and the drying box 2 are detachably fixed on the base 3 by screws, and the inside of the drying box 2 is provided with a heating plate 16, Use heating to evaporate the water on the steel strip after cleaning, so as to prevent the steel strip from being easily oxidized due to the water on the surface after cleaning, which will affect the quality. The rollers supporting the steel strip prevent the steel strip from scratching the surface of the steel strip due to friction between the steel strip and the drying box 2 inlet, outlet and inner wall.

[0030] On the base 3 and on the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com