Equally divided eccentric ball socket fine grinding tooling and processing method

A fine grinding and fine machining technology, applied in the field of mechanical processing, can solve the problems of difficult to guarantee the position size and surface profile of the ball socket, sharp increase in manufacturing cost, difficult to guarantee the position size, etc., to improve the machining accuracy and economic benefits, reduce Consumption of manpower and material resources, the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

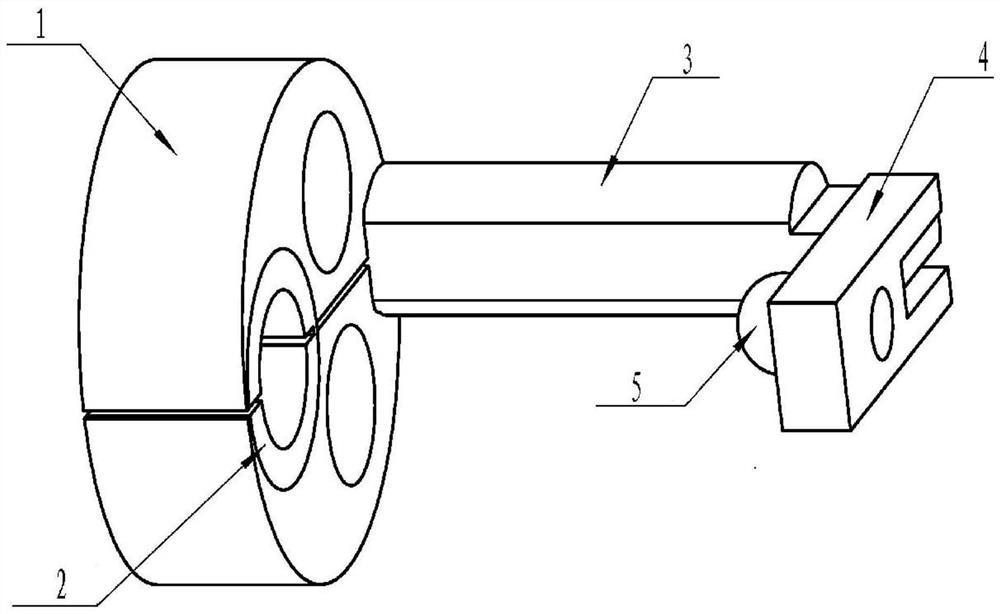

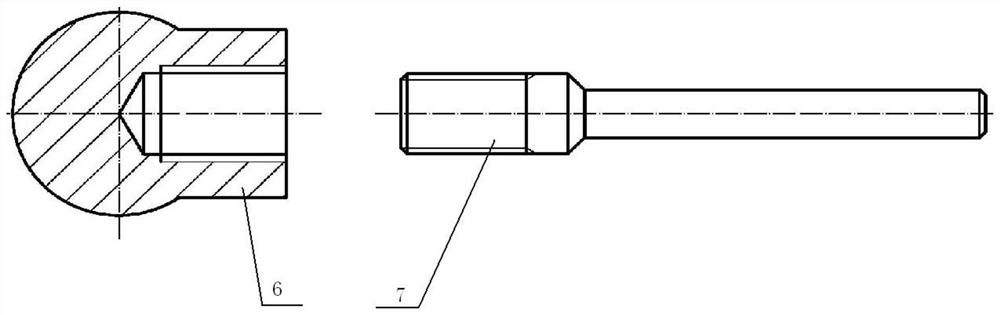

[0027] see figure 2 , the present invention provides an equally divided eccentric ball and socket fine grinding tool, the equally divided eccentric ball and socket fine grinding tool includes an eccentric sleeve 1, a positioning ball 5 and a split spherical grinder; the axis where the eccentric sleeve 1 is located and the split spherical grinder The axes are coincident; the eccentric sleeve 1 is provided with a part installation hole; the positioning ball 5 is movably connected with the eccentric sleeve 1; the center of the positioning ball 5 is on the axis of the eccentric sleeve 1; the part to be processed 8 is placed on the eccentric sleeve through the part installation hole 1, and adjust the ball socket to be finely machined on the part 8 to be processed by the positioning ball 5, so that the center of the ball socket of the ball socket to be finely processed is on the axis of the eccentric sleeve 1; the split spherical grinder is aligned on the part to be processed 8. To...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com