System and method for automatic operational tool replacement of live working robot

A technology for live work and work tools, applied in the system field of live work robots automatically replacing work tools, can solve problems such as pinching operators, tools falling, complex structure, etc., to achieve compact structure, improve replacement efficiency, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

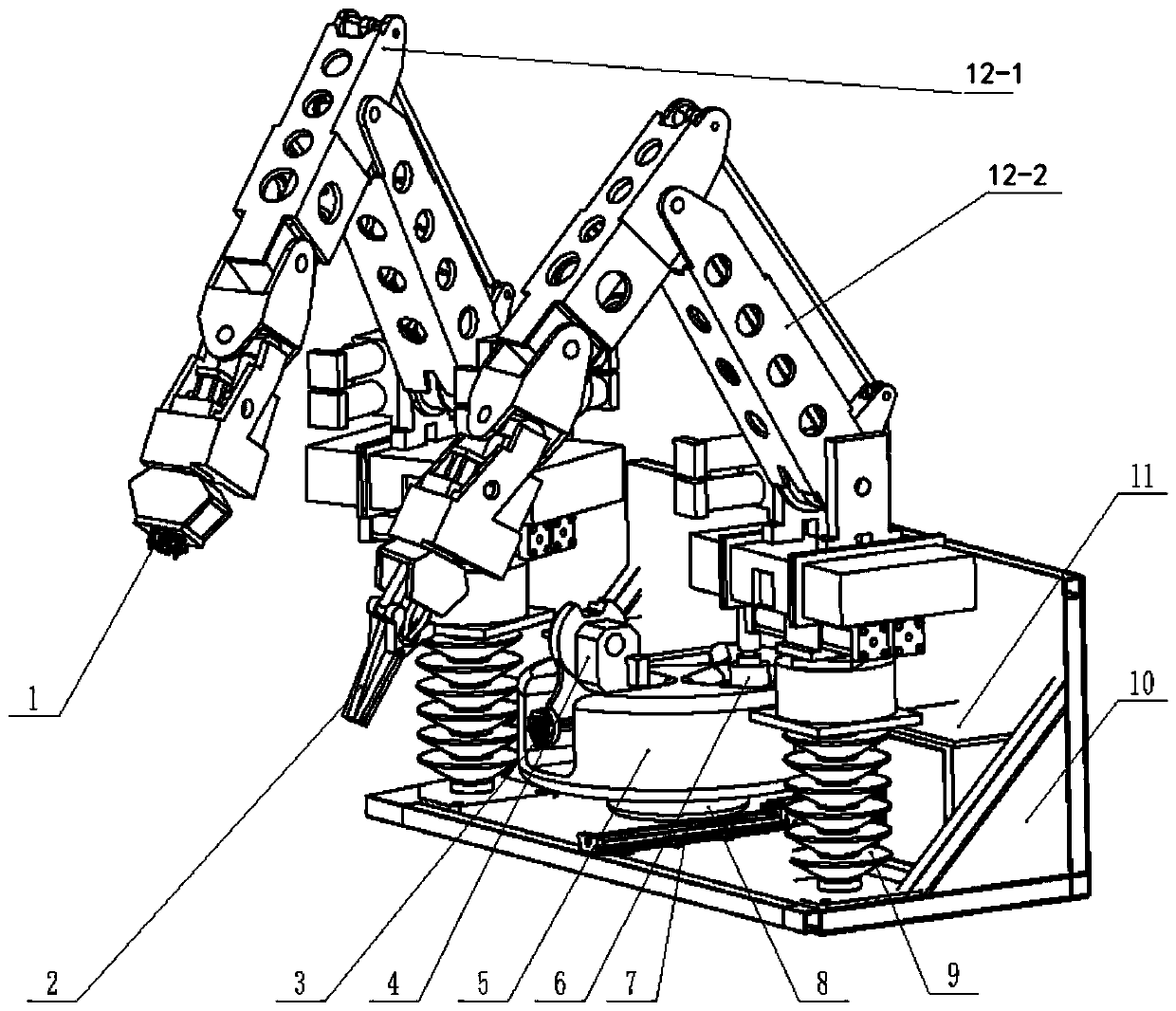

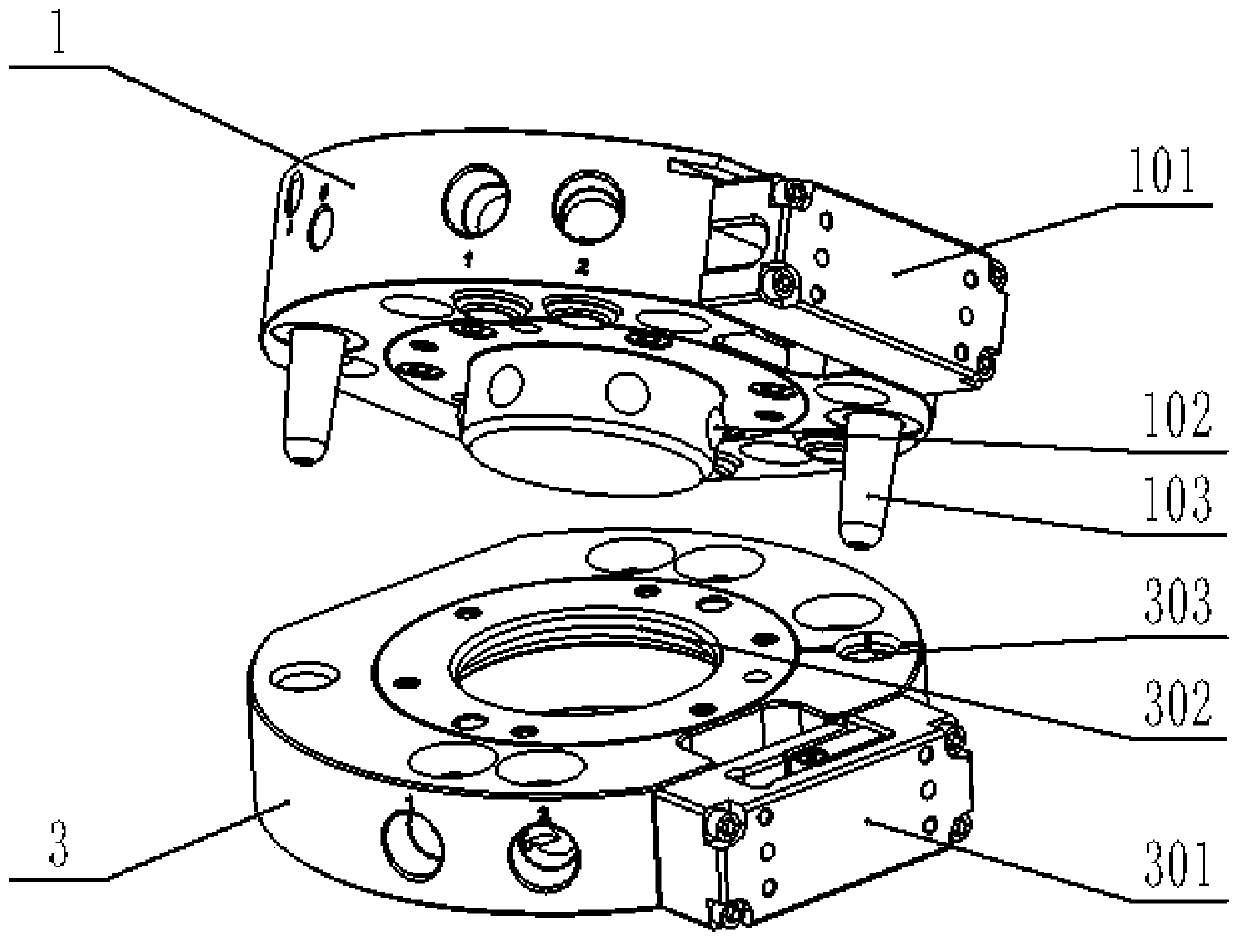

[0028] In one or more embodiments, a system for automatically changing tools of a live working robot is disclosed, including: a live working platform 10, on which a working robot arm 12-1 and a tool changing mechanism are respectively arranged; The tool replacement mechanism includes a rotating part and a tool magazine 5 arranged on the rotating part; at least two live working tools are arranged in the tool magazine 5, and each live working tool is provided with a working robot arm 12- 1 One-touch fittings that match the end fittings.

[0029] Exemplary, see figure 1 , the live working platform 10 is respectively equipped with a working robot arm 12-1, a wire clamping robot arm 12-2, a screw guide rail pair 7, a rotating mechanism 8 and a tool magazine 5;

[0030] Wherein, the operation manipulator 12-1 and the wire clamping manipulator 12-2 are connected to the live work platform 10 through the post insulator 9, and one work manipulator 12-1 is installed on each post insulat...

Embodiment 2

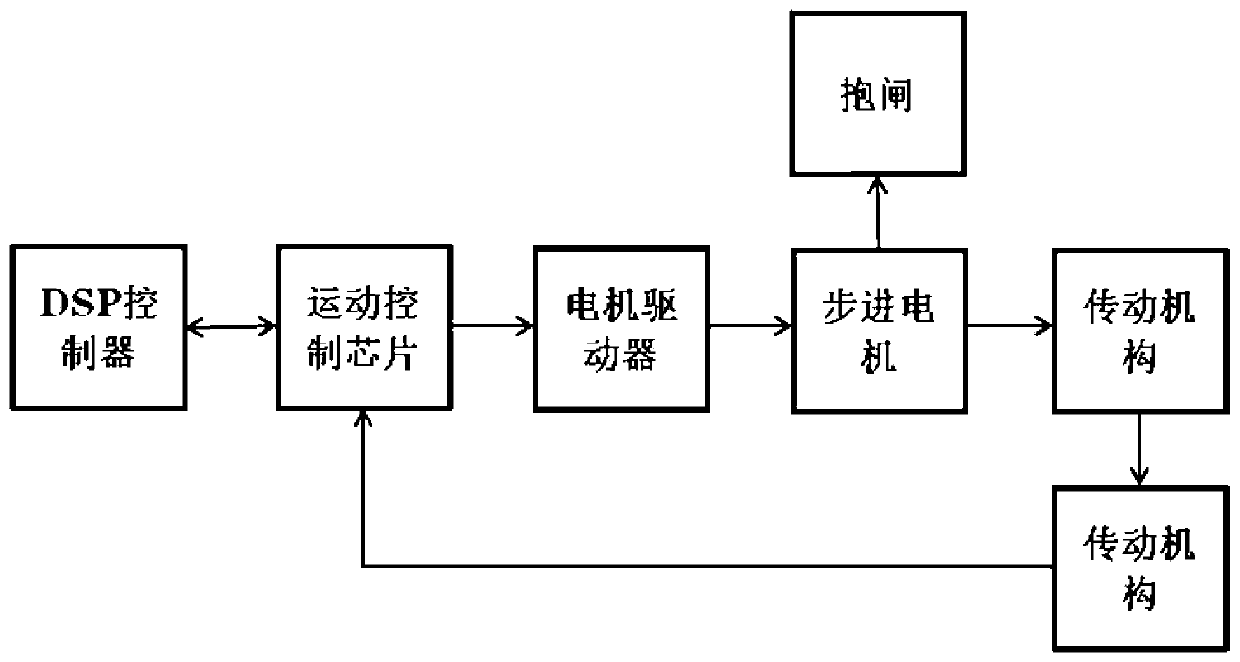

[0046] In one or more embodiments, a method for automatic tool replacement of a live working robot is disclosed, including three processes of tool selection, tool positioning and tool replacement.

[0047] 1) Tool selection

[0048] Put the used tools into the tool library 5 sequentially according to the process requirements, code each tool, and select the tool according to the coding of the tool library 5 . Select tool by coding during operation, and the used tool is put back in the original tool storehouse 5 .

[0049] 2) Tool positioning

[0050] According to the instruction received to replace the working tool, match the corresponding working tool through coding;

[0051] Rotate the tool magazine 5 to rotate the corresponding operating tool to the set position;

[0052] 5-position locking of the tool magazine;

[0053] Start the tool replacement mechanism, and drive the motor to rotate forward or reverse to return to the original position. Send the tool selection comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com