Self-service 3D insole printing system and device

A 3D printing and printing system technology, applied in the detection field, can solve problems such as insufficient 3D printing insole operating system or mode, no clear management of user private information, loss of invisible customers, etc., to achieve high stability and reliability, and save manpower The effect of reducing cost and reducing the cycle of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

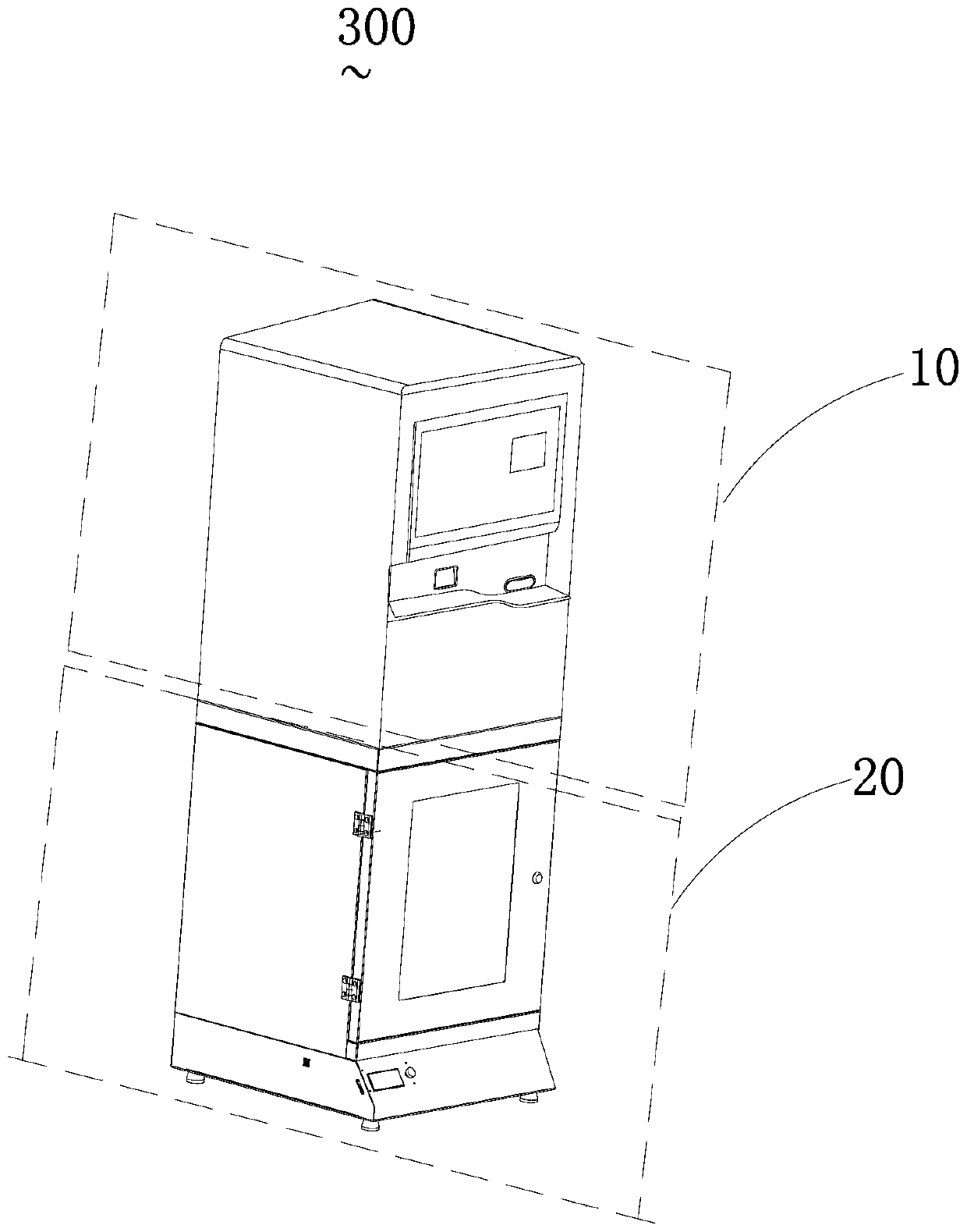

[0052] Embodiment 1: A self-service 3D insole printing device

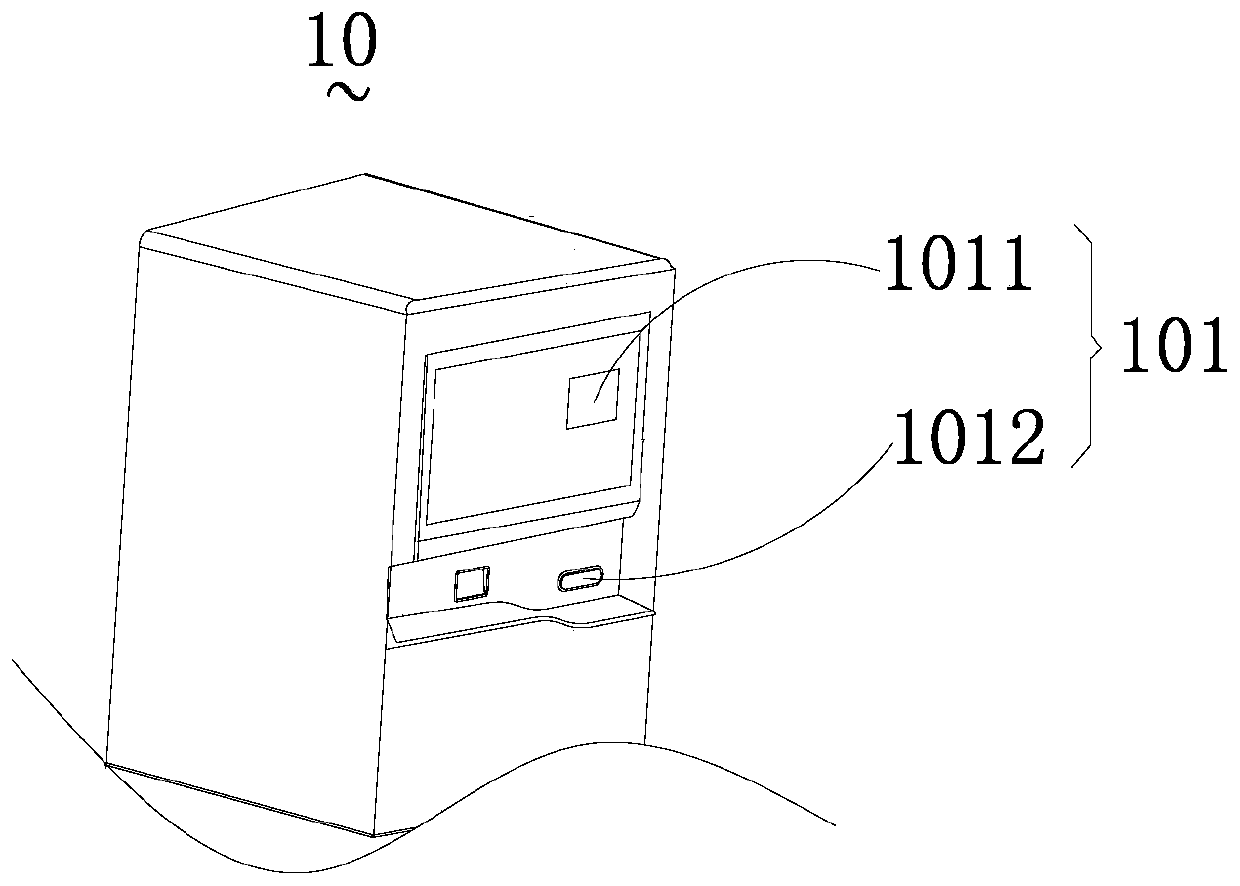

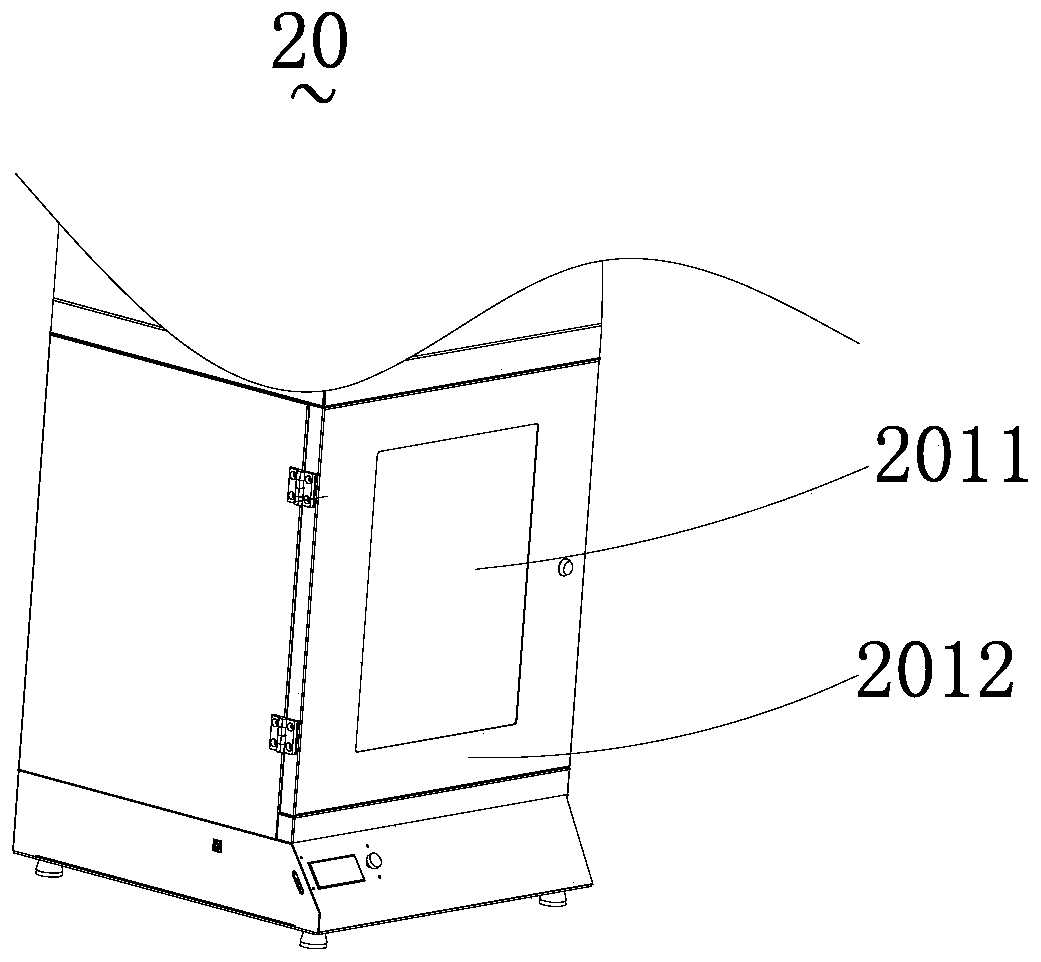

[0053] The self-service 3D insole printing device 300 includes a self-service printing mechanism 10 and a self-service measuring mechanism 20, wherein the self-service printing mechanism 10 is mainly used for printing 3D printed insoles, and the self-service measuring mechanism 20 is used for information interaction with users to obtain user information of users. Information; wherein the specific positional relationship between the self-service printing mechanism 10 and the self-service measuring mechanism 20 is not set, preferably, the self-service measuring mechanism 20 is set up on the lower side of the self-service printing mechanism 10, that is, the side close to the ground; it can be understood that, in In the field of 3D printed insoles, the insole itself is a customized product, so "user information" is a technical vocabulary commonly used by people in this industry.

[0054] see figure 2 as well as im...

Embodiment 2

[0074] Embodiment 2: A self-service 3D insole printing system

[0075] see Figure 17 , for the convenience of explaining the overall solution, Embodiment 2 provides a self-service 3D insole printing system, the system includes a client 100, a control unit 200, a printer 300, and a cloud platform 400, wherein the client 100 can be a self-developed 3D printing insole APP, the control unit 200 is a single-chip microcomputer or an industrial computer, that is, the above-mentioned industrial computer.

[0076] The printer 300 is a self-service 3D printing device. The user terminal 100 uploads the user information specified on it to the cloud platform 400. After receiving the user information, the cloud platform 400 uses force analysis to match the corresponding 3D printed insole modeling and generates a printing program. , wherein the cloud platform 400 and the control unit 200 can realize information connection, that is, the cloud platform 400 sends it to the control unit 200 ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com