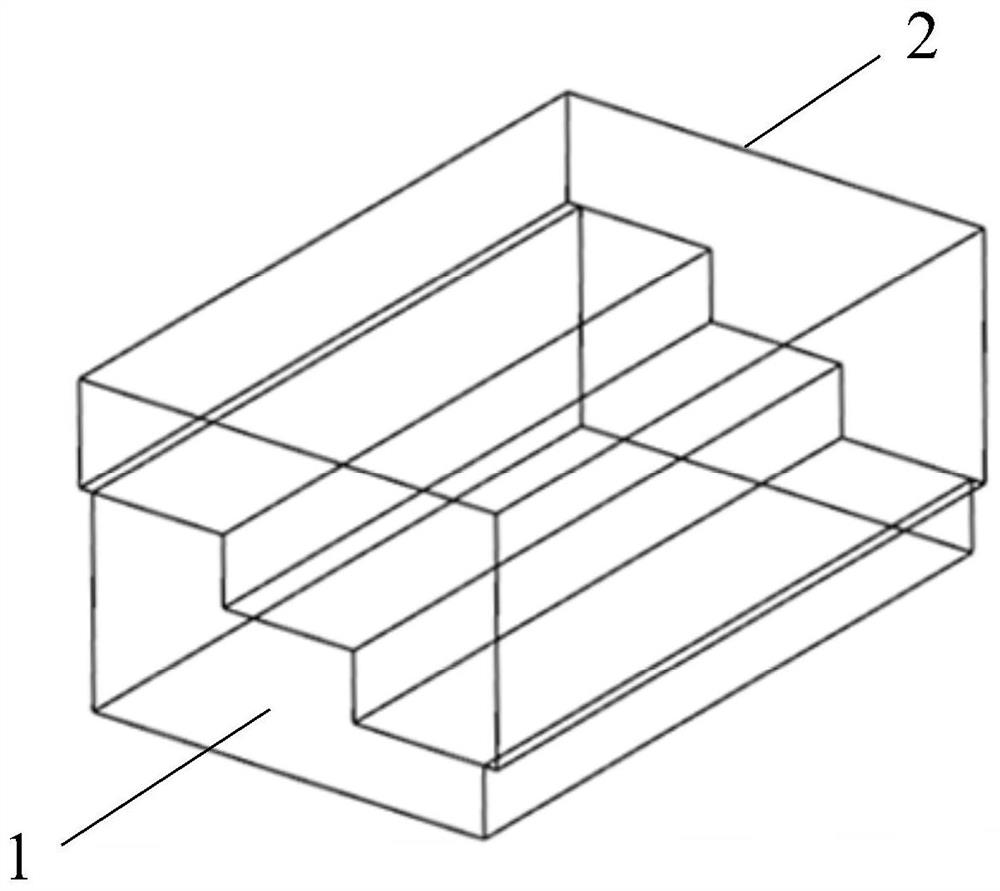

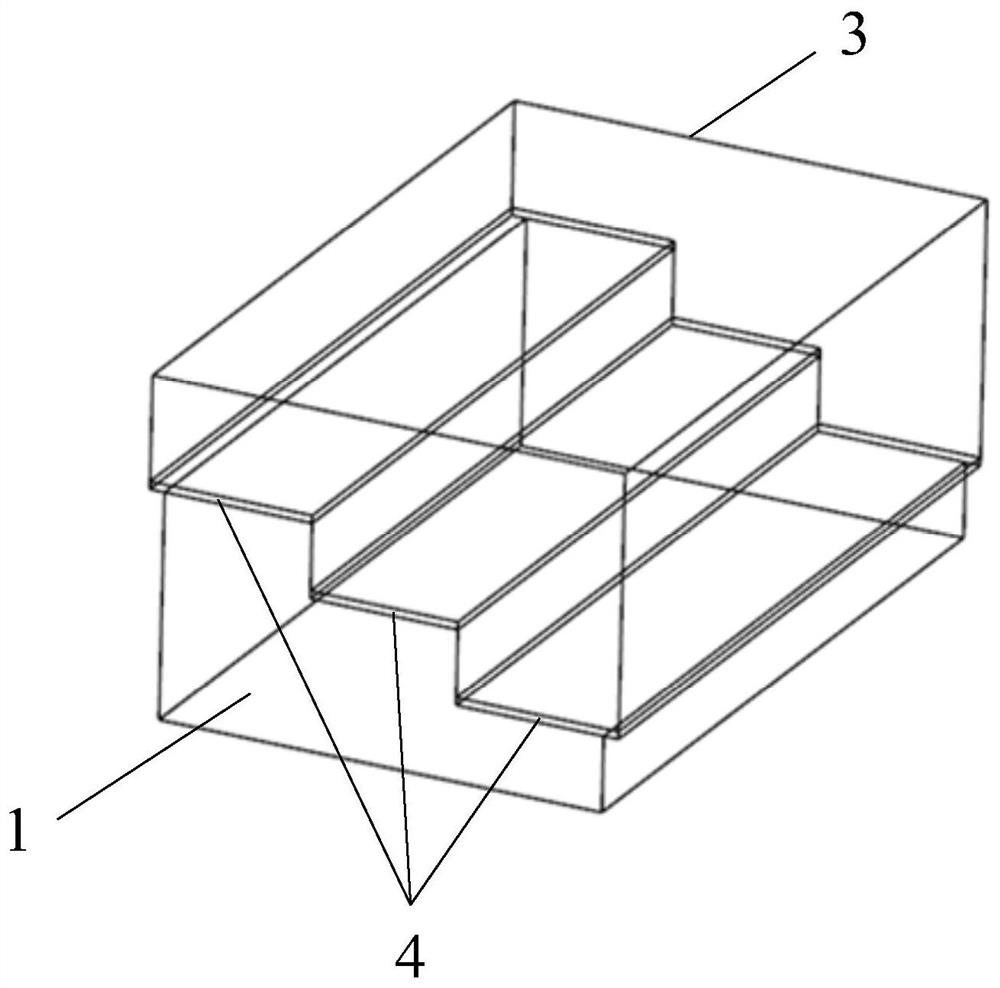

A composite material multi-step platform and its high-quality forming method

A composite material and molding method technology, which is applied in the field of composite material multi-step platform molding, can solve problems such as difficulty in ensuring the coordinated pressing of steps, and achieve the effects of improving product qualification rate and molding quality, low cost, and high molding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] For a 2mm-high composite ladder formed by a high step of 4mm and a low step of 2mm, the high-quality molding method includes the following steps:

[0059] ①Using P20 die steel (hard die steel) machine plus hard die.

[0060] ② Determine the compression amount of the composite material step (composite material step): 4*0.1=0.4 for the high step, 2*0.1=0.2 for the low step, and 1MPa for high-quality molding pressure (curing pressure).

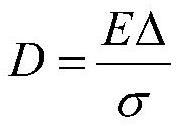

[0061] 3. It is determined that the replacement material is rubber (low modulus material), and its compression modulus is 7.8MPa, and the thickness of the low modulus material is matched with the modulus of the low modulus material:

[0062]

[0063] Determine the thickness of the replacement rubber: the high step is determined to be 3.12mm, and the low step is determined to be 1.56mm.

[0064] ④ According to the principle of equal thickness replacement, determine the replacement thickness of the high modulus material on the side of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com