Crushing pipe anti-bending device for motor train unit

A technology for crushing tubes and EMUs, used in transportation and packaging, railway car body parts, buffers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of a crush pipe anti-bending device for multiple train sets will be described in detail below in conjunction with the accompanying drawings and specific examples.

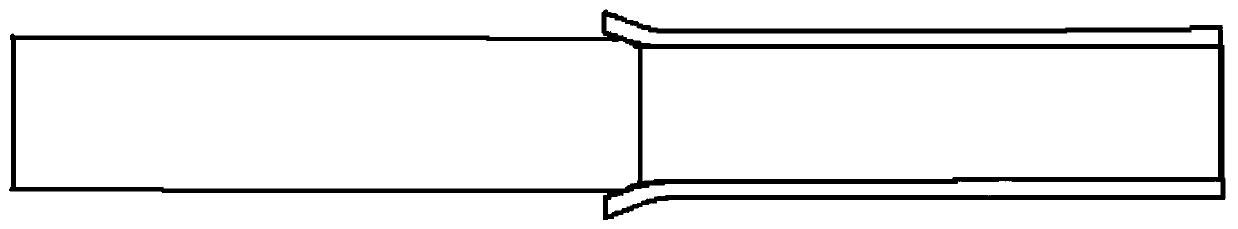

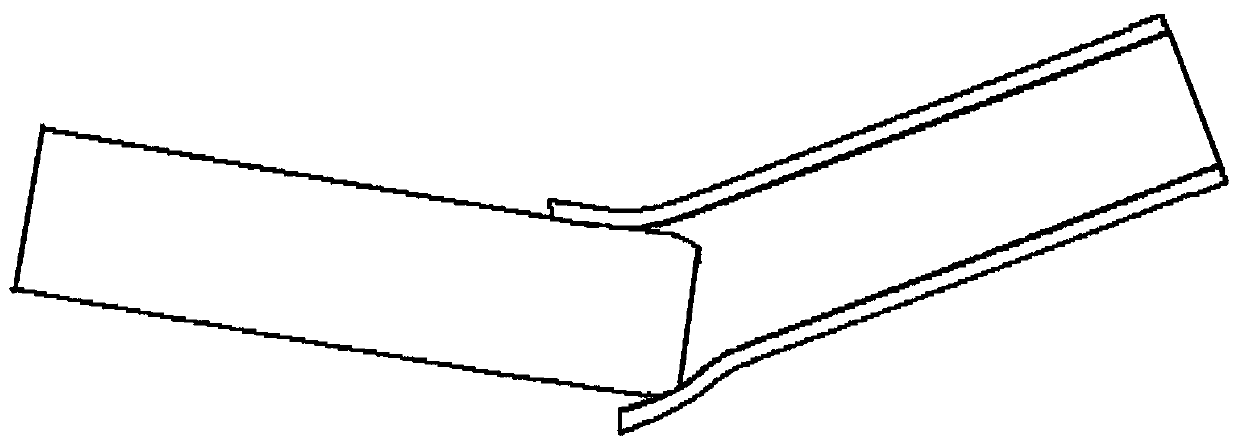

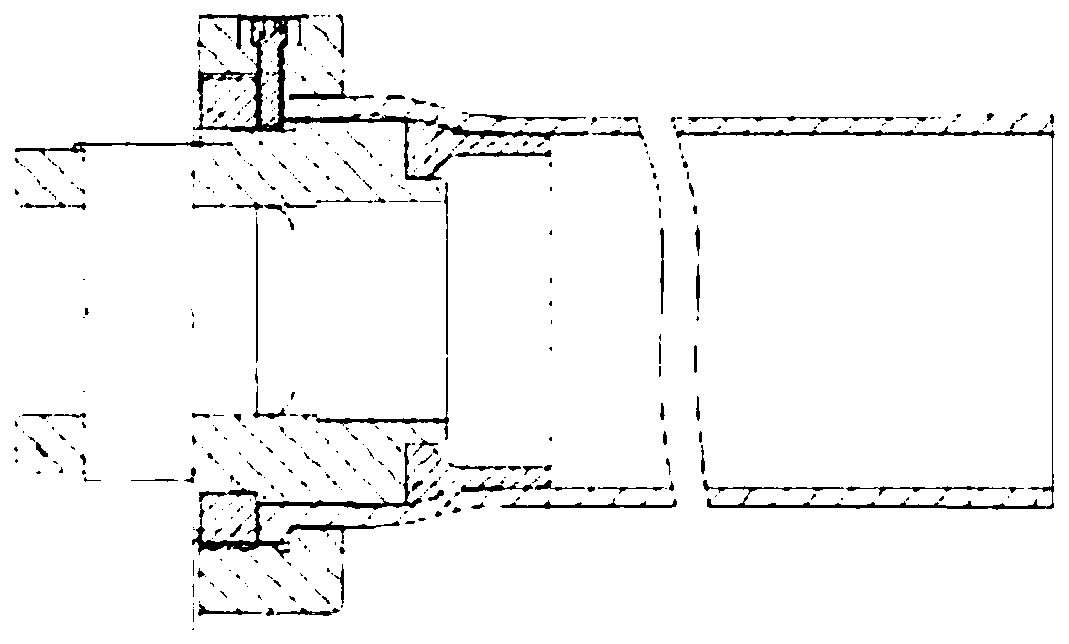

[0020] Such as figure 1 As shown, a crush pipe anti-bending device for EMUs includes a base 1 , a guide rod 3 , an expansion cone 4 , a contraction ring 5 , an inner sleeve 6 , a middle sleeve 2 , and an outer sleeve 7 . The guide rod 3 is coaxially arranged in the middle sleeve 2, a gap is provided between the middle sleeve 2 and the guide rod 3, a limit hole 10 is provided in the middle of the guide rod 3, and the middle sleeve 2 The head end of the guide rod 3 is fixed on the first base 1, and the tail end is open. The outer sleeve 7, the inner sleeve 6 and the positioning rod 9 are coaxially fitted sequentially from the outside to the inside. The outer sleeve 7 and the inner sleeve 6 are provided with a gap, the inner sleeve 6 and the positioning rod 9 are provided with a gap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com