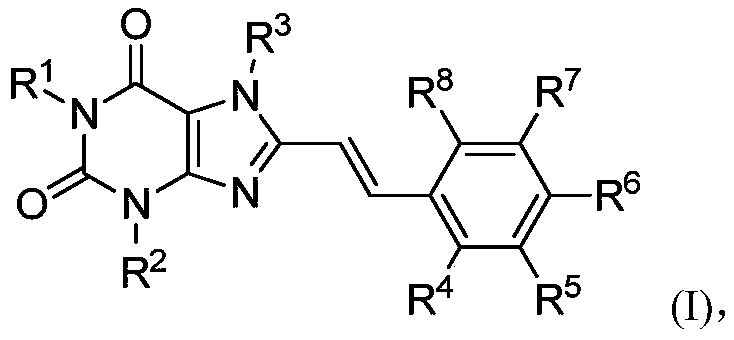

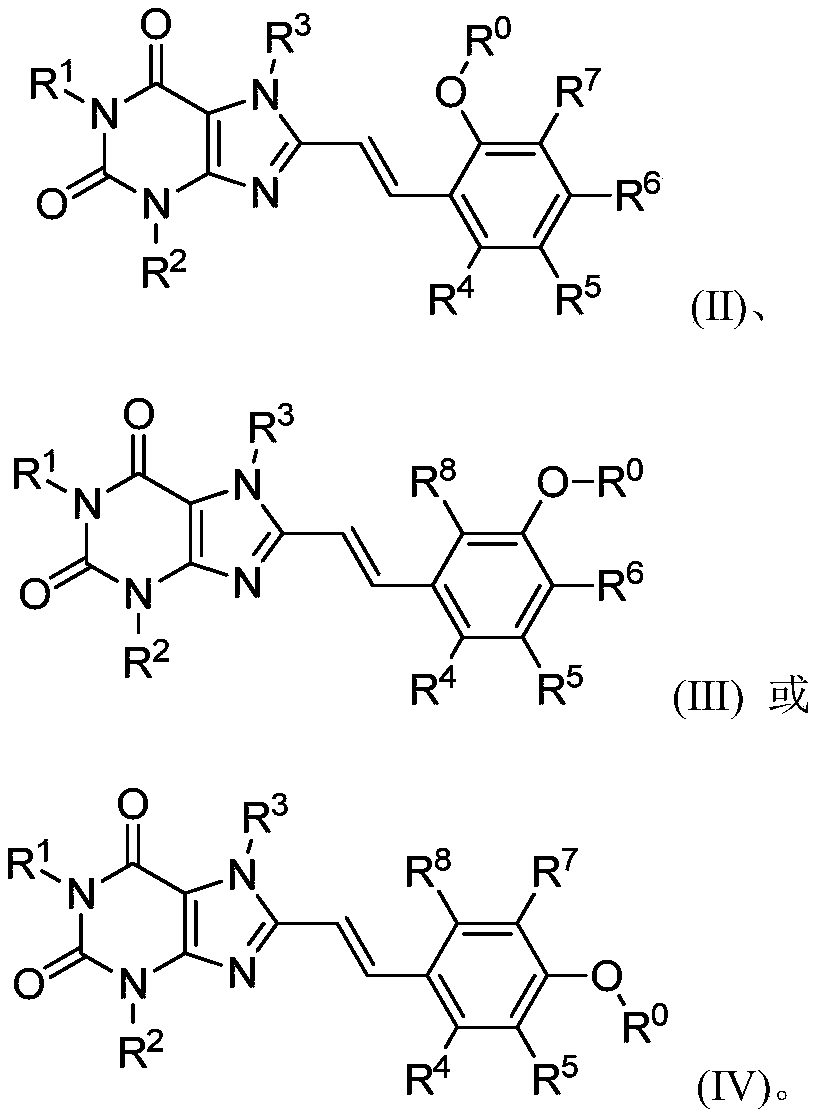

8-substituted styryl xanthine derivative and application thereof

An alkyl and group technology, which is applied in the direction of drug combinations, active ingredients of heterocyclic compounds, cardiovascular system diseases, etc., can solve problems such as distribution restrictions of adenosine A, achieve a good brain/plasma ratio, good clinical application prospects, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

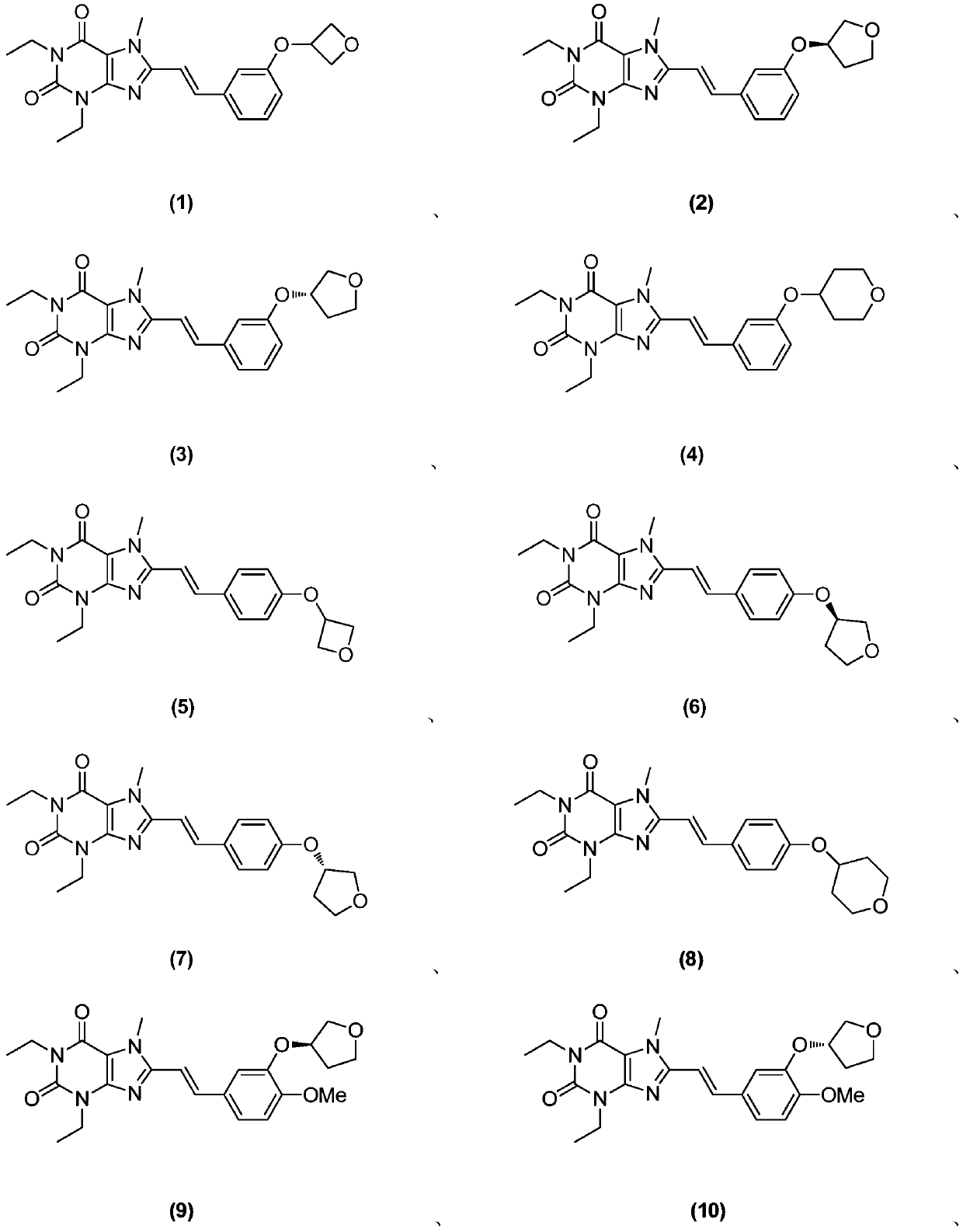

Embodiment 1

[0269] Example 1 (E)-1,3-diethyl-7-methyl-8-(3-(oxetan-3-yloxy)styryl)-1H-purine-2,6( Synthesis of 3H,7H)-diketones

[0270]

[0271] Step 1) Synthesis of oxetan-3-yl 4-methylbenzenesulfonate

[0272] Add p-toluenesulfonyl chloride (1.0g, 5.2mmol) and triethylamine (2.2mL, 15.7mmol) into a 100mL single-necked flask at 25°C, add dichloromethane (10mL), and then add oxetane in batches Alkan-3-ol (0.5g, 6.7mmol), continue to react for 24 hours; add water (40mL), then add dichloromethane (20mL), separate the liquid, collect the organic phase, spin dry under reduced pressure, and separate by column chromatography Purification (petroleum ether / ethyl acetate (v / v)=10 / 1~5 / 1) gave the title compound as a pale yellow solid (1.02 g, 85.2%).

[0273] MS(ESI,pos.ion)m / z:229.1[M+H] + ;

[0274] 1 H NMR (400MHz, CDCl 3 )δ (ppm) 7.81 (d, J = 8.2Hz, 2H), 7.39 (d, J = 8.1Hz, 2H), 5.38–5.28 (m, 1H), 4.76–4.66 (m, 4H), 2.49 (s ,3H).

[0275] Step 2) Synthesis of 3-(oxetan-3-yloxy)b...

Embodiment 2

[0291] Example 2 (R, E)-1,3-diethyl-7-methyl-8-(3-((tetrahydrofuran-3-yl)oxy)styryl)-1H-purine-2,6 Synthesis of (3H,7H)-diketones

[0292]

[0293] Step 1) Synthesis of (S)-tetrahydrofuran-3-yl 4-methylbenzenesulfonate

[0294] The title compound of this step was prepared by referring to the method described in step 1 of Example 1, that is, p-toluenesulfonyl chloride (3.6g, 18.9mmol), (S)-tetrahydrofuran-3-ol (1.5g, 17.0mmol) and triethylamine (3.5mL, 24.9mmol) was prepared by reaction in dichloromethane (20mL). The crude product was separated and purified by silica gel column chromatography (petroleum ether / ethyl acetate (v / v)=20 / 1) to obtain the title compound as red Brown oil (2.8 g, 68.0%).

[0295] MS(ESI,pos.ion)m / z:265.0[M+Na] + ;

[0296]1 H NMR (400MHz, CDCl3) δ (ppm) 7.80 (d, J = 8.3Hz, 2H), 7.36 (d, J = 8.1Hz, 2H), 5.17–5.06 (m, 1H), 3.92–3.78 (m, 4H), 2.46(s,3H), 2.13–2.04(m,2H).

[0297] Step 2) Synthesis of (R)-3-((tetrahydrofuran-3-yl)oxy)benzaldehy...

Embodiment 3

[0315] Example 3 (S, E)-1,3-diethyl-7-methyl-8-(3-((tetrahydrofuran-3-yl)oxy)styryl)-1H-purine-2,6 Synthesis of (3H,7H)-diketones

[0316]

[0317] Step 1) Synthesis of (R)-tetrahydrofuran-3-yl 4-methylbenzenesulfonate

[0318] The title compound of this step was prepared by referring to the method described in Step 1 of Example 1, that is, p-toluenesulfonyl chloride (3.0 g, 16 mmol), (R)-tetrahydrofuran-3-ol (1.5 g, 17.0 mmol) and triethylamine ( 3.5mL, 24.9mmol) was prepared by reaction in dichloromethane (20mL). The crude product was separated and purified by silica gel column chromatography (petroleum ether / ethyl acetate (v / v)=20 / 1) to obtain the title compound as reddish brown Oil (2.2 g, 58.0%).

[0319] MS(ESI,pos.ion)m / z:265.2[M+Na] + ;

[0320] 1 H NMR (400MHz, CDCl 3 )δ (ppm) 7.80 (d, J = 8.3Hz, 2H), 7.36 (d, J = 8.1Hz, 2H), 5.17–5.06 (m, 1H), 3.89–3.81 (m, 4H), 2.46 (s ,3H),2.13–2.04(m,2H).

[0321] Step 2) Synthesis of (S)-3-((tetrahydrofuran-3-yl)ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com