Dyeing method based on carbon dioxide supercritical dispersion mutual dissolution

A carbon dioxide and dyeing method technology, applied in the dyeing field, can solve the problems of high workload, low dyeing efficiency, and inability to discharge directly, so as to avoid the investment of manpower and material resources, improve the utilization rate, and ensure the uniformity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

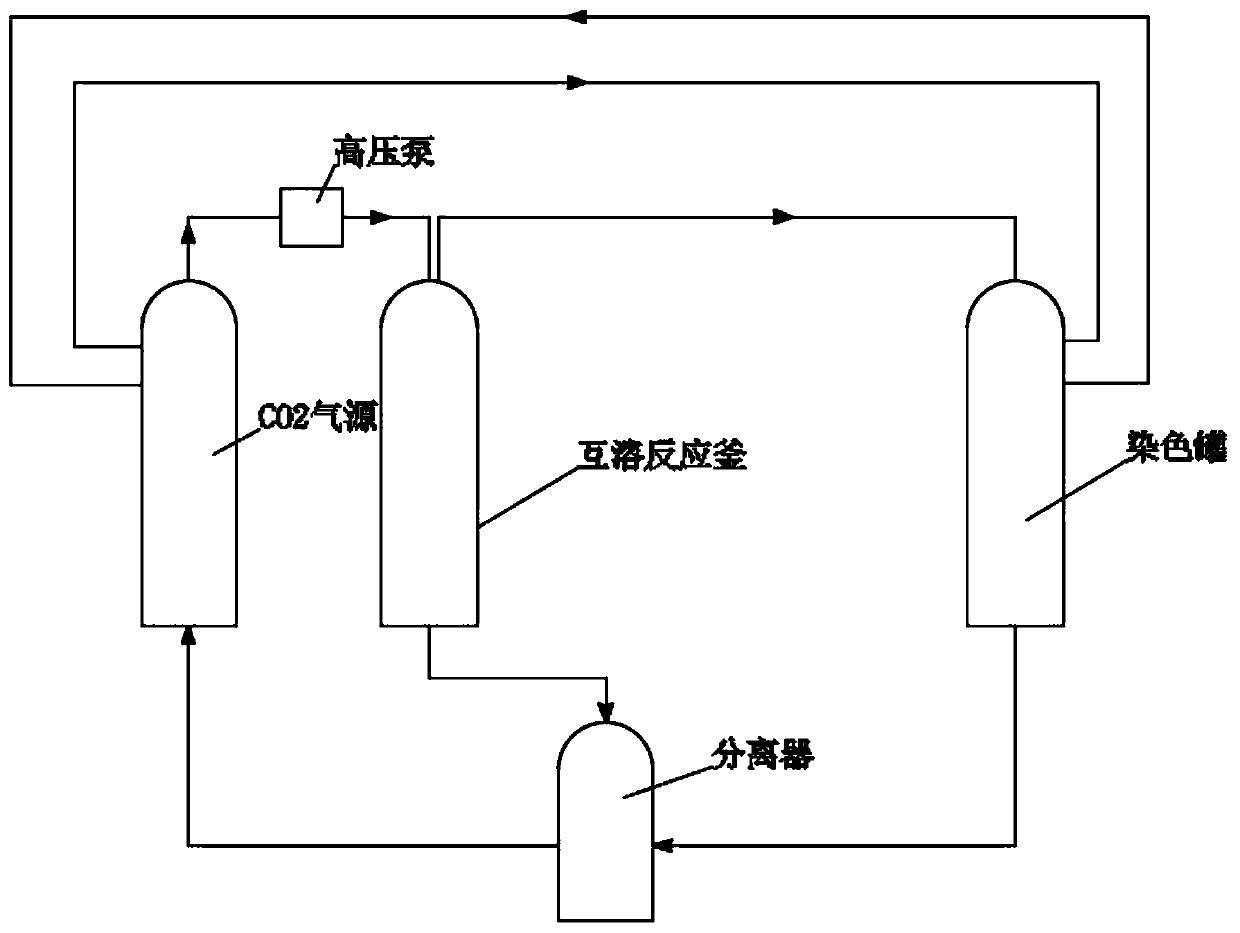

[0050] see figure 1 , a kind of dyeing method based on carbon dioxide supercritical dispersion and mutual dissolution, comprising the following steps:

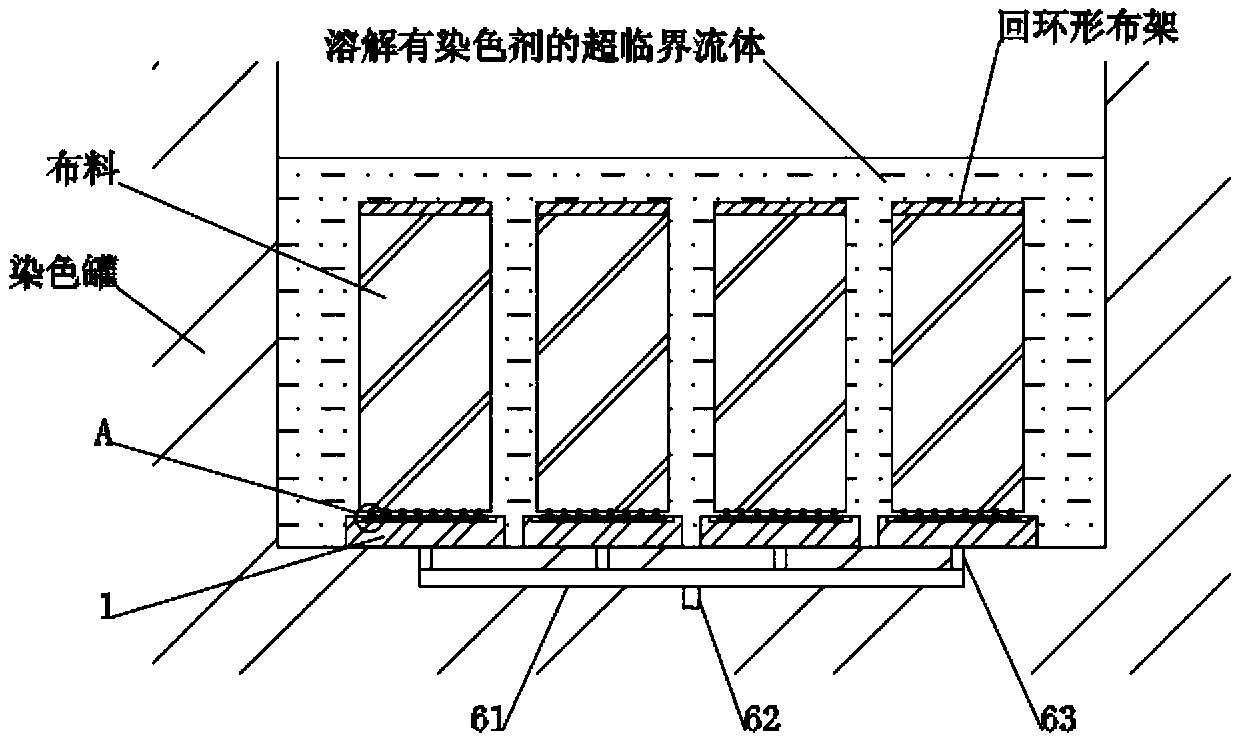

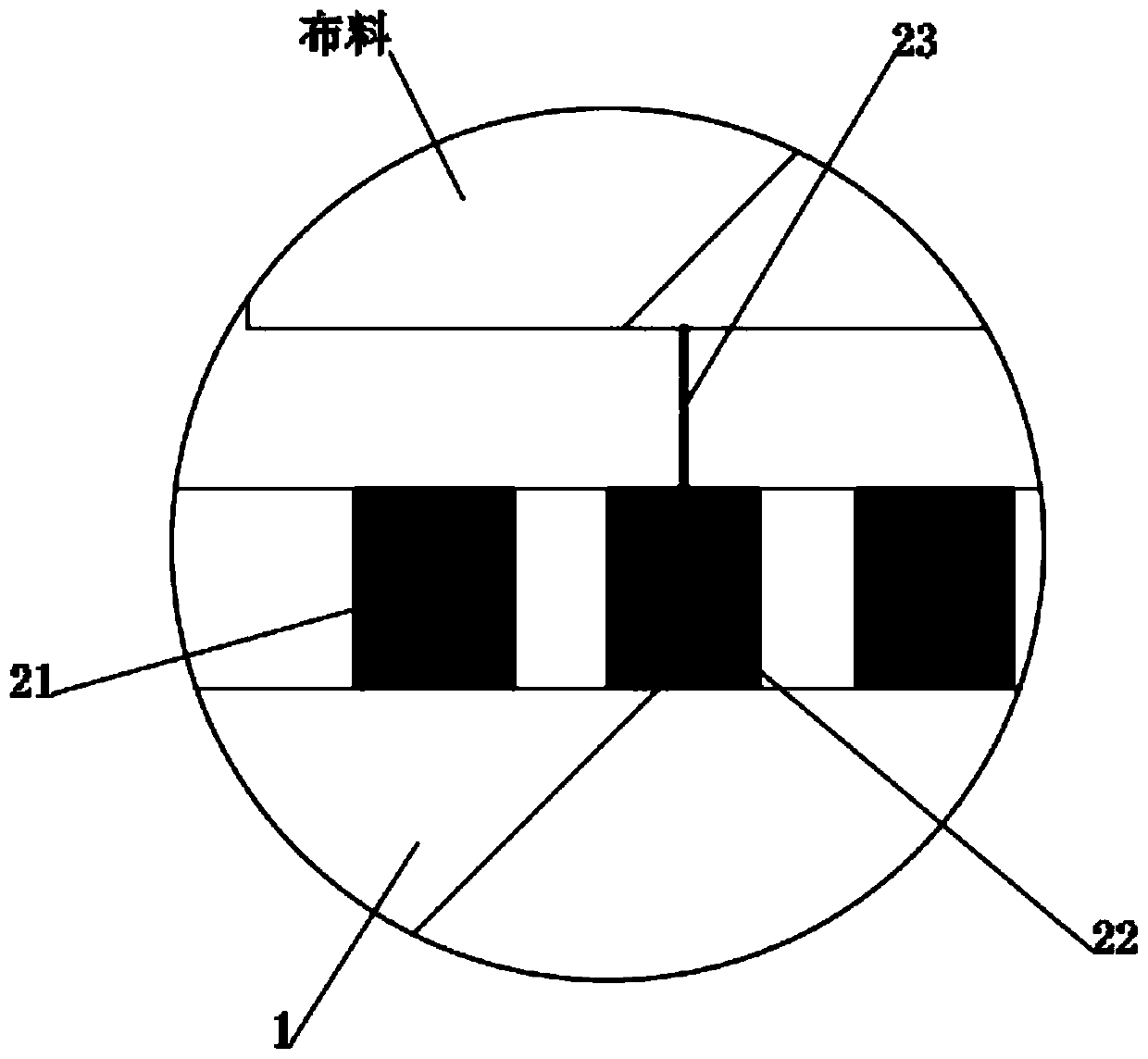

[0051] S1, first put the dyeing agent prepared according to the needs into the mutual dissolving reaction kettle, and put the cloth to be dyed on the spiral layer roll rack 3 of the dyeing tank, and then adjust the temperature and air pressure in the mutual dissolving reaction kettle;

[0052] S2. Pump CO2 from the CO2 gas source to the mutual dissolution reactor through the high-pressure pump, and the CO2 will be in a supercritical state in the mutual dissolution reactor to dissolve the dye;

[0053] S3, passing the supercritical fluid dissolved with the dyeing agent into the dyeing tank, and dyeing the cloth to be dyed on the spiral layer roll frame 3 of the dyeing tank;

[0054] S4. After the dyeing is finished, the dyed supercritical fluid dissolved in the dyeing agent in the dyeing tank and the remaining supercritical fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com