Retaining wall reverse filter drain hole embedded part and construction method thereof

A construction method and retaining wall technology, which are applied in waterway systems, water supply devices, sewer pipeline systems, etc., can solve the problems of difficulty in ensuring the construction quality of the reverse filter layer or filter bag, complicated construction procedures, and many mutual interferences. The effect of reducing the investment of personnel and machinery in the construction of the retaining wall anti-filter structure, saving the construction period and ensuring the stability of the soil mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

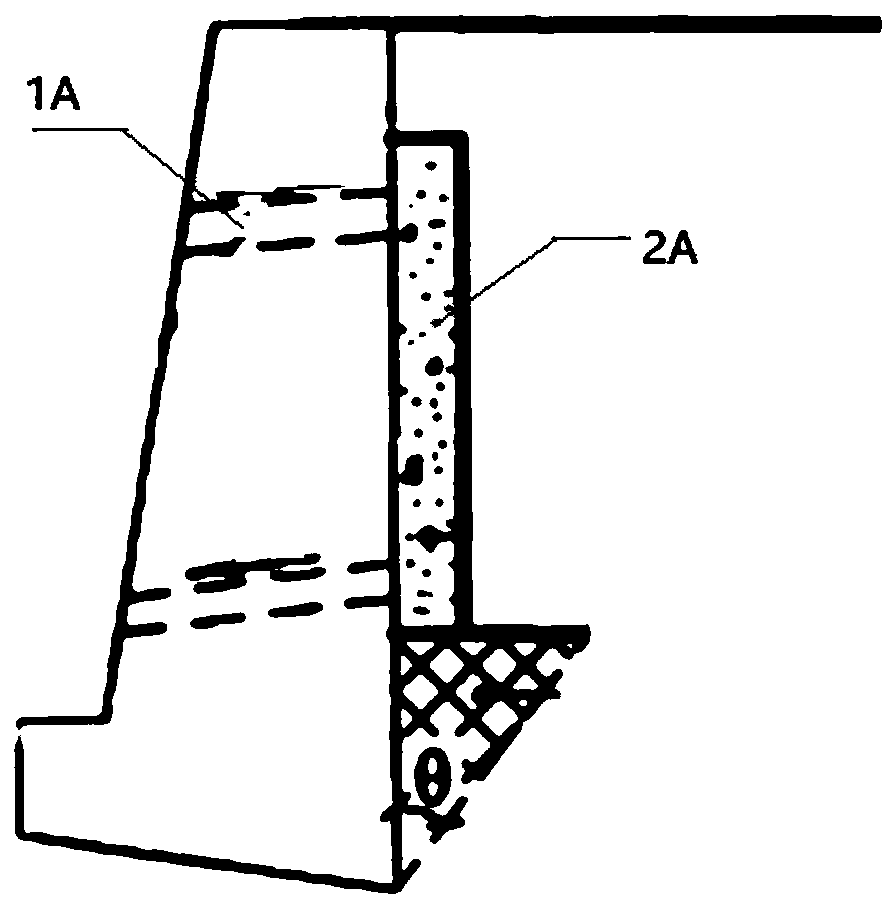

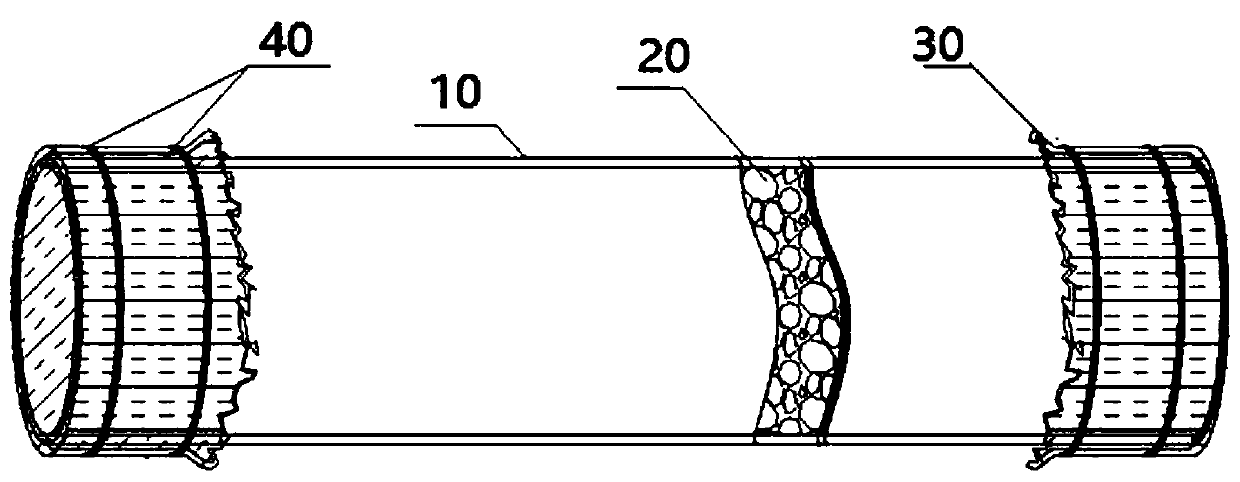

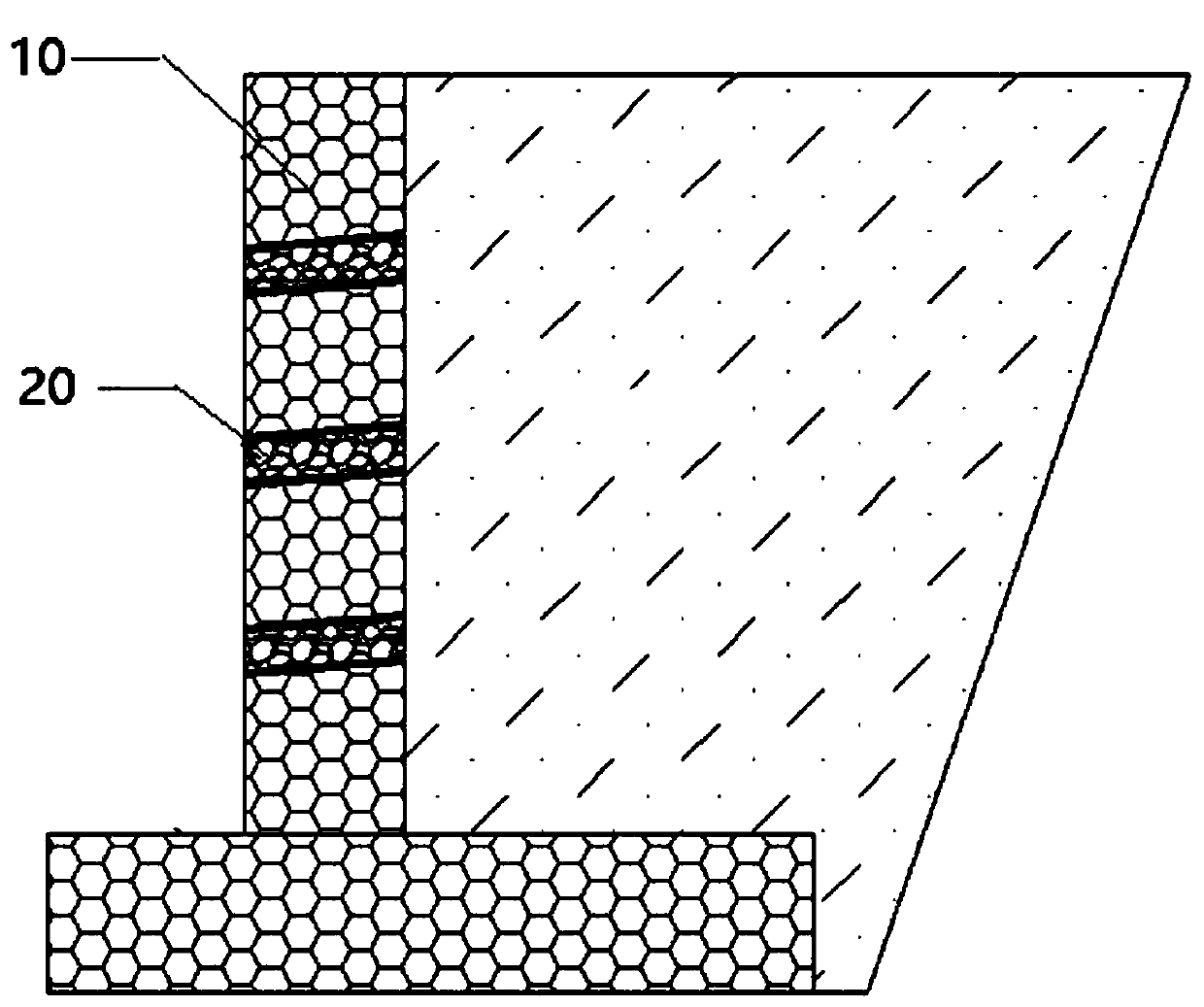

[0031] Such as Figure 2-5 As shown, the present invention provides a pre-embedded component 1 for reverse filtration weep holes in a retaining wall, including a casing 10, at least one drainage reverse filter layer 20, and at least two permeable layers 30; wherein the drainage reverse filter The layer 20 is horizontally intercepted and arranged in the casing 10 to further intercept the water flowing through the casing 10; two layers of the water-permeable layer 30 are respectively coated on both ends of the casing 10 to prevent the inflow The water inside the casing 10 is filtered. The sleeve 10 may be implemented as a PVC sleeve in actual implementation.

[0032] In the above-mentioned embodiment, the pre-embedded part of the anti-filtration drain hole of the retaining wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com