Stiffened steel concrete connecting joint and application method thereof

A technology for connecting joints and concrete, which is applied in the direction of construction and building structure, and can solve problems such as insufficient anchorage length, influence on the strength of steel columns, and errors in drilling holes, so as to facilitate quality control, improve operation efficiency, and ensure anchorage quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

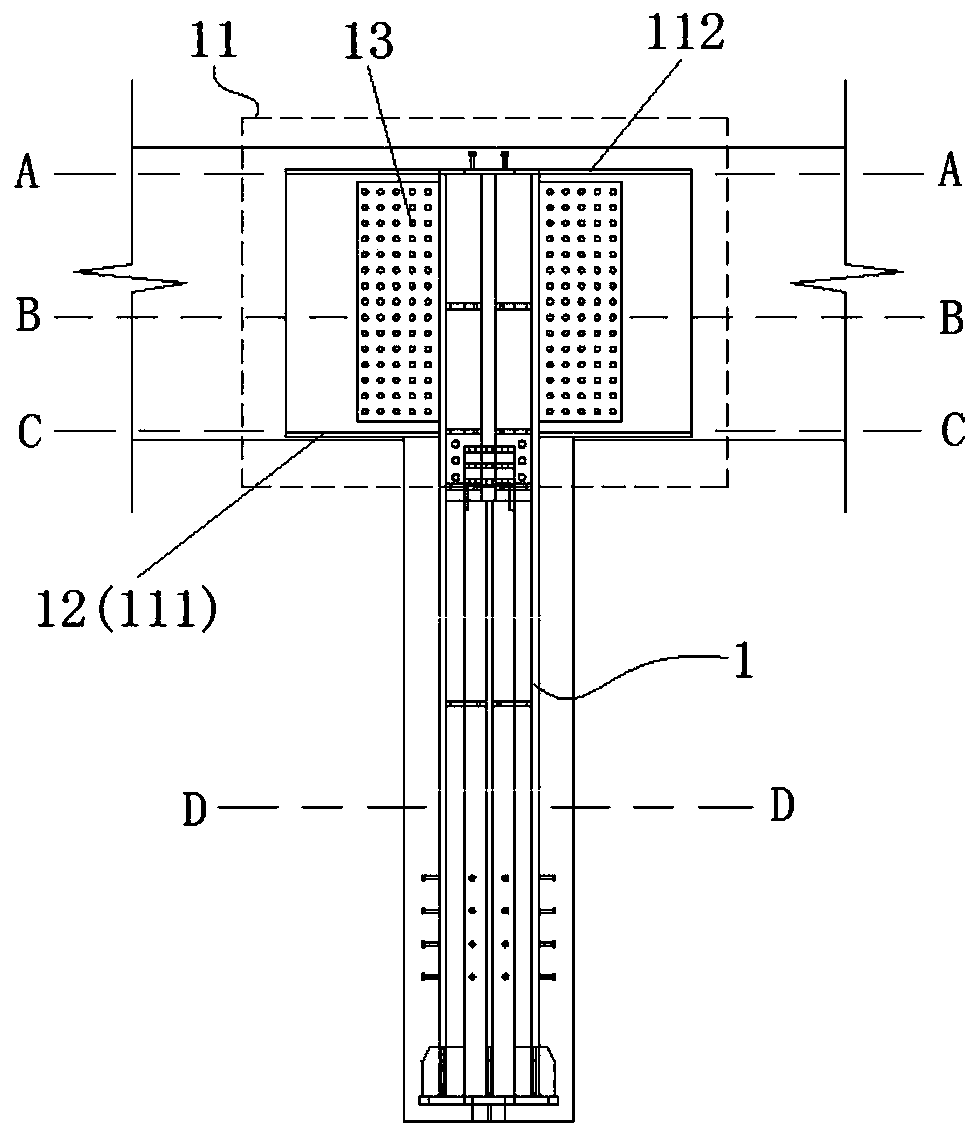

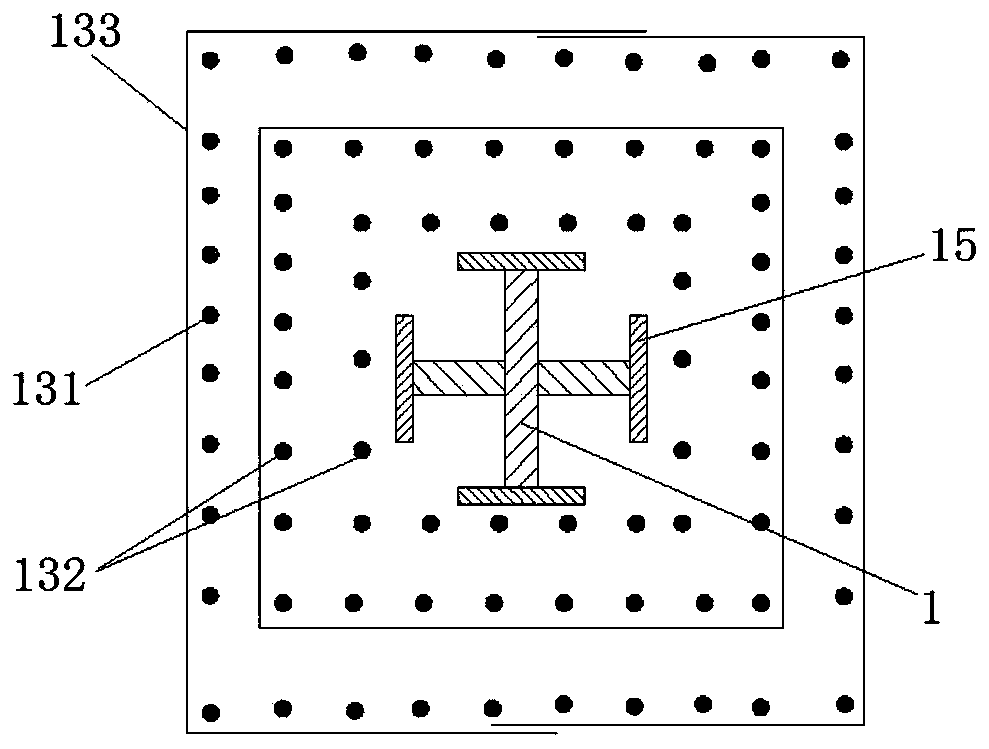

[0051] Such as Figure 1-9 As shown, this embodiment provides a steel-concrete connection node, including steel columns 1 and several beams 2 .

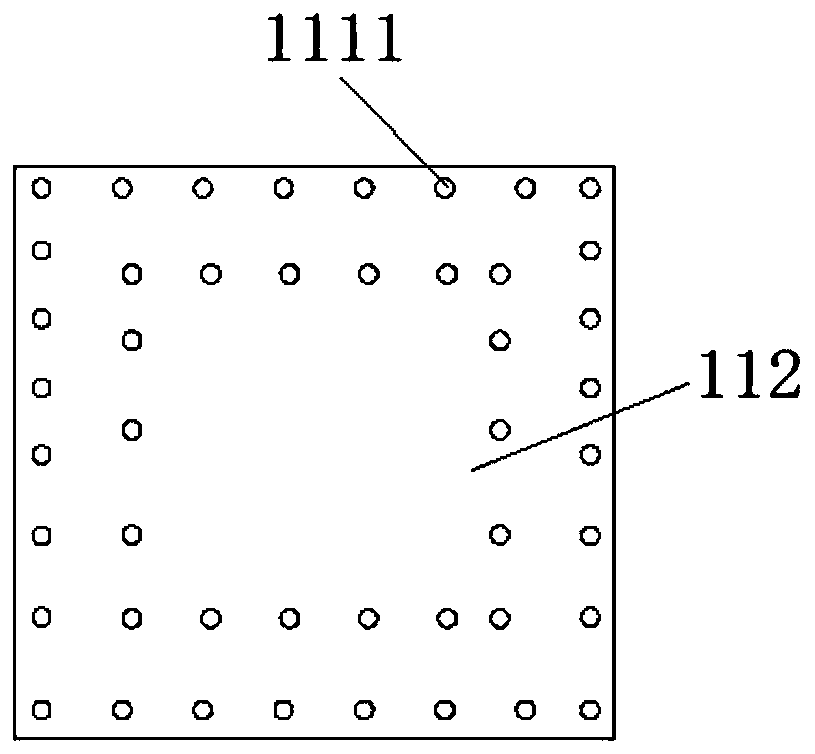

[0052] Further, the beam connection part 11 is arranged on the steel column 1, and the bottom end of the beam connection part 11 is provided with several connection steel plates 111, and the connection steel plates 111 are provided with via holes 1111, and the several connection steel plates 111 It is welded and connected with the shaped steel column 1 to form a support platform 12 , and several node steel bars pass through the through holes 1111 to form a reinforcement cage 13 on the support platform 12 .

[0053] As a preferred solution, a top steel plate 112 is provided at the top of the beam connecting portion 11, and a plurality of via holes 1111 are also provided on the top steel plate 112; so that on the shaped steel column 1, the A space is formed between the top steel plate 112 and the support platform 12 for setting the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com