Optimization control method for combustion of quadrangular tangential boiler based on optimization of air distribution mode

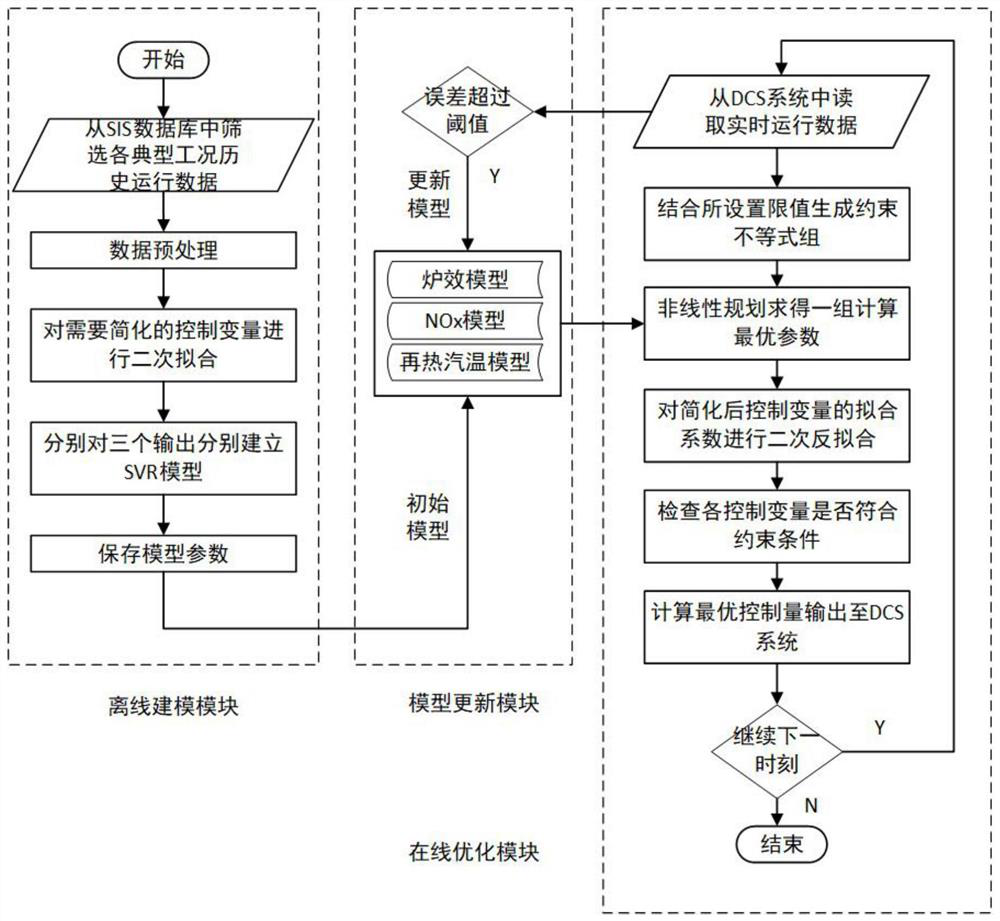

A technology of four-corner tangential circle and boiler combustion, which is applied in the direction of combustion control, manufacturing computing system, character and pattern recognition, etc. It can solve the problem of online model updating, combustion optimization, difficulty in online solution, slow algorithm calculation speed, and high data sparsity, etc. problem, to achieve the effect of ensuring self-adaptive ability, improving computing speed and reducing input volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0146] Example: A 600MW unit adopts the SG-2028 / 17.5-M908 boiler manufactured by Shanghai Boiler Factory, with subcritical parameters, four-corner tangential combustion mode, one-time intermediate reheating, single furnace balanced ventilation, solid slag discharge, tight seal, π-type drum furnace with all-steel structure. Equipped with 6 sets of medium-speed coal mills A-F, 5 of which are in operation and 1 is in standby. The number of coal feeders is T=6, the number of burn-off air layers is F1=7, the number of perimeter air layers is F2=6, and the number of secondary air layers is F3=7.

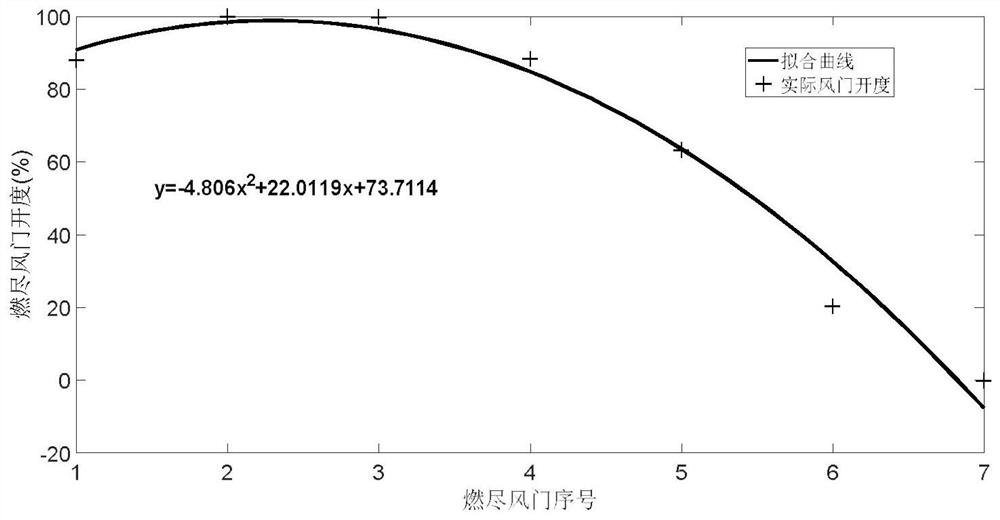

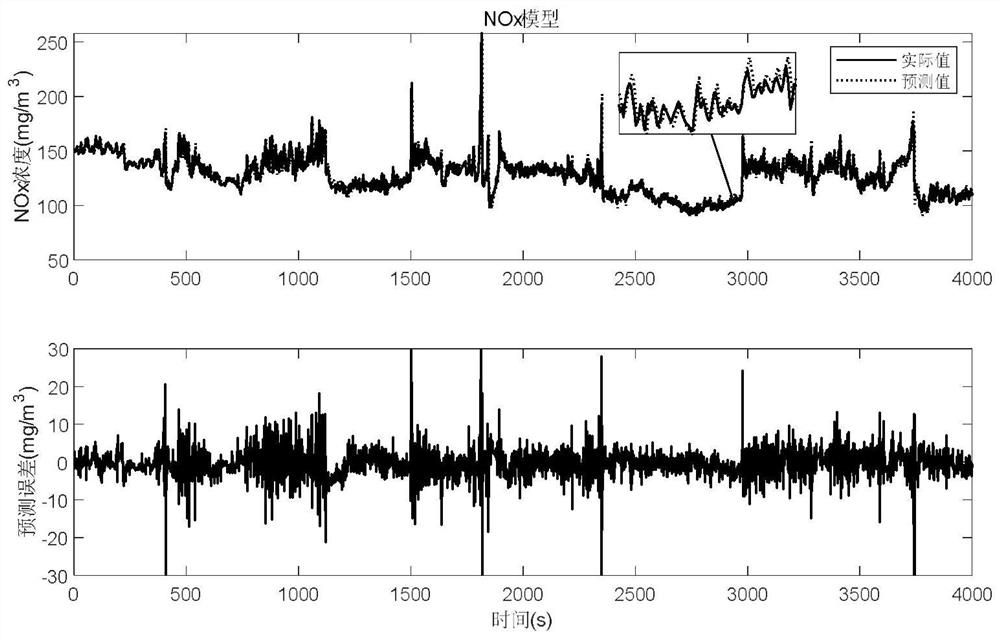

[0147] Step 1: Screen a total of 500 sets of operating data under various typical working conditions from the SIS system. The specific operating data include the model input shown in Table 1, boiler efficiency, NOx concentration at the inlet of the denitrification system (SCR), and reheat steam temperature output. The least squares fitting is carried out on the four types of control quan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com