Fire test furnace cooling and purifying system and method

A fire test furnace and purification system technology, which is applied in the field of fire test furnace cooling and purification system, can solve the problems of smoke exhaust pipe damage, inability to effectively control the pressure of the furnace and smoke exhaust pipe, lack of flue gas cooling, etc., to improve the purification capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

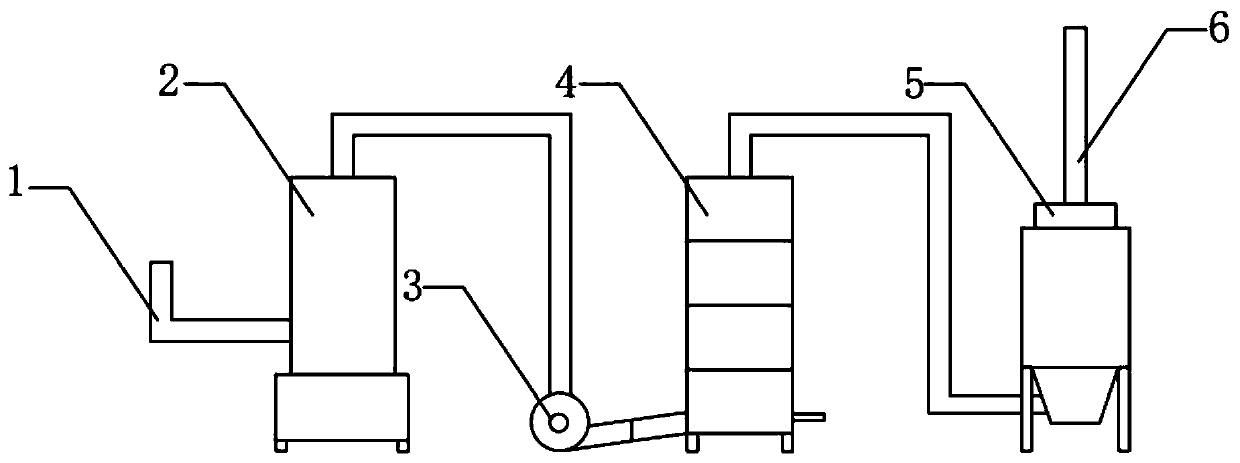

[0034] Such as figure 1 As shown, Embodiment 1 of the present disclosure provides a cooling and purification system for a fire test furnace, including a fire test furnace smoke exhaust pipe 1, the fire test furnace smoke exhaust port has a shutter, and the fire test furnace smoke exhaust pipe 1 The end is connected to the air inlet near the bottom of the cooling tower 2, and the upper outlet of the cooling tower 2 is connected with a centrifugal fan 3, and the centrifugal fan 3 is connected to a plurality of drying box groups 4, and the drying box group 4 passes through the pipeline It is connected with the electrostatic precipitator 5, and the upper end of the electrostatic precipitator 5 is connected to the high-altitude chimney 6.

[0035] Described purification system also comprises master controller, and described master controller collects the parameter data and flue gas data of cooling water tower 2, centrifugal fan 3, drying box group 4 and electrostatic precipitator 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com