Centering system and method for large-caliber concave aspheric surface

A technology of aspheric surface and target ball, which is applied in the field of centering system of large-diameter concave aspheric surface, can solve the problems of insufficient and high centering accuracy, and achieve the effects of improving work efficiency, reducing measurement difficulty, and reducing optical design difficulty

Active Publication Date: 2020-04-10

BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

View PDF9 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The technical solution of the present invention is to provide a centering system and method for a large-diameter concave aspheric surface to improve the centering accuracy of the large-diameter concave aspheric mirror, in view of the situation that the centering accuracy of the large-diameter concave aspheric mirror is not enough or the accuracy and range of the test instrument are too high. Central accuracy, improve test convenience, and reduce the cost of test instruments

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

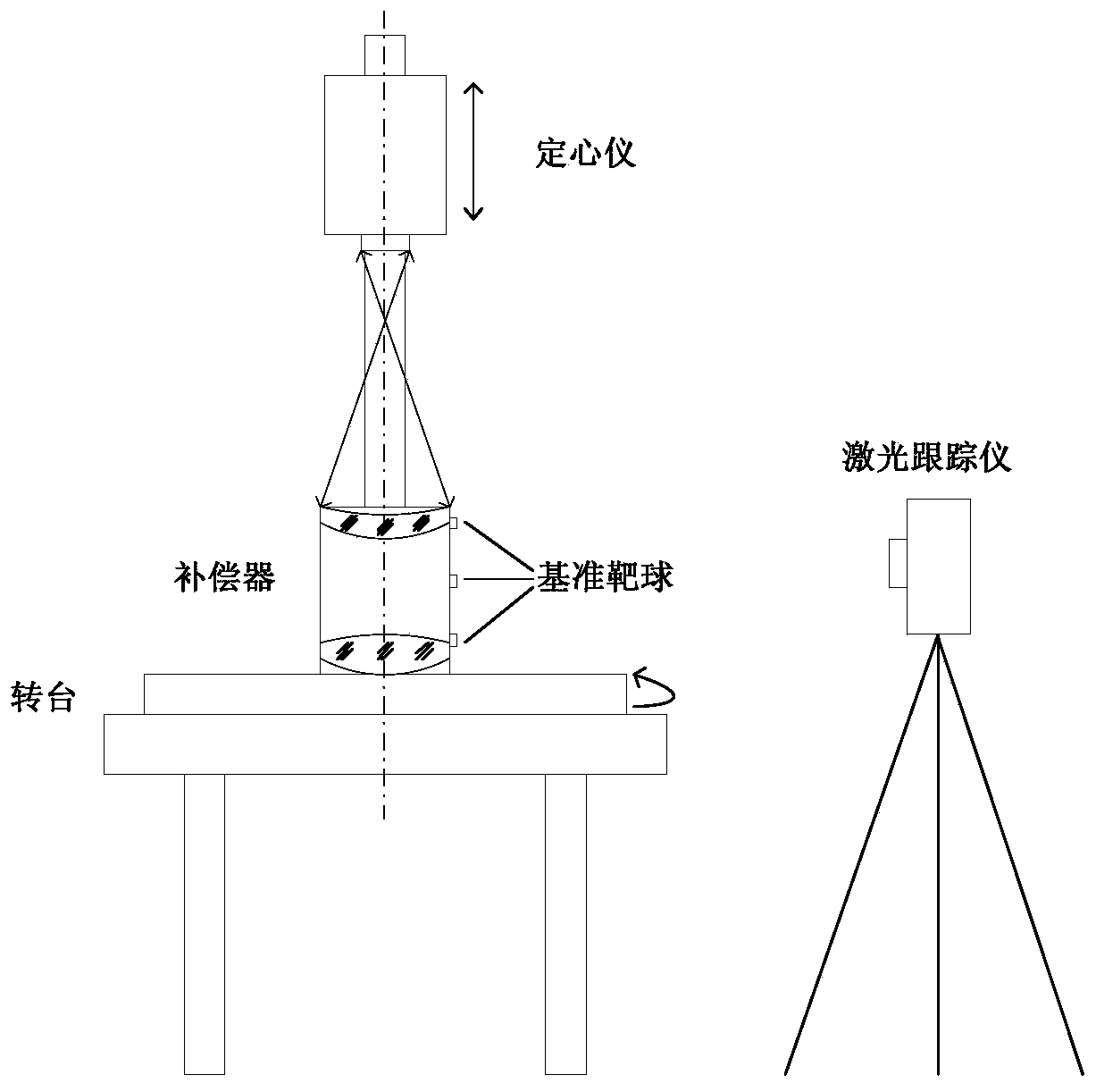

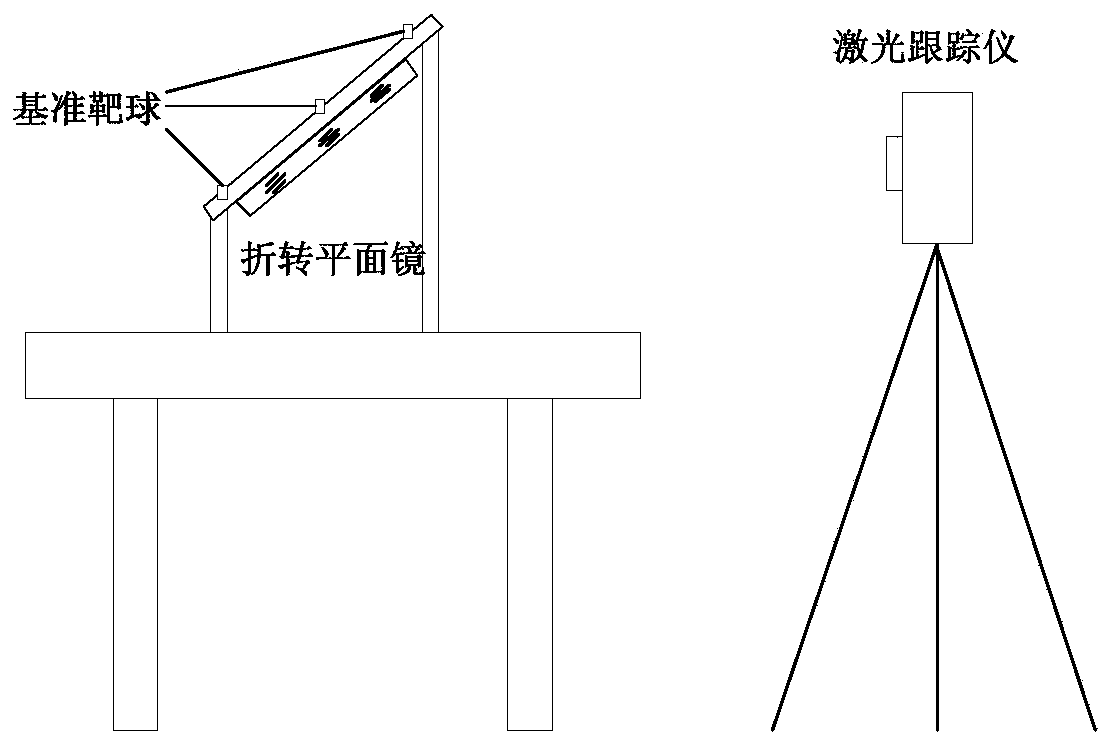

[0085] The test method mentioned in the invention is applied in the process of testing the optical axis of the primary mirror of the remote sensor lens of a certain type of remote sensing satellite. The test site is an optical laboratory, and the temperature and humidity requirements of the laboratory are 20±2°C and 30%-60% humidity. Stick the SMR firmly on the appropriate positions of the compensator, folding plane mirror and primary mirror.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

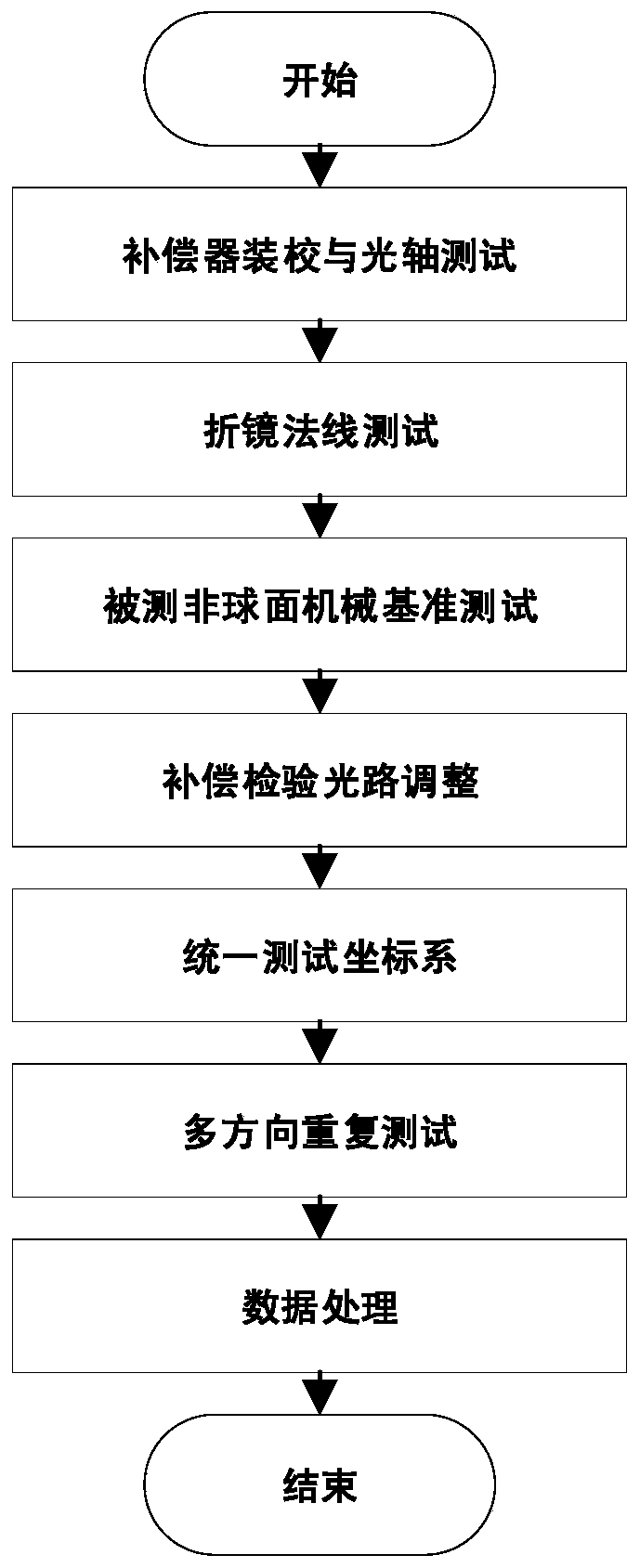

The invention relates to a centering system and method for a large-caliber concave aspheric surface, and belongs to the technical field of space optical adjustment and test, in a zero compensation interference test light path for converting an optical axis into a vertical optical axis, optical axes of an interferometer, a compensator and a tested aspheric surface are superposed through position adjustment and system aberration test; the optical axis of the compensator, the normal of the folding mirror and the mechanical reference of the measured aspheric surface are measured and calculated byusing a laser tracker; the relative position relationship between the optical axis and the mechanical reference is embodied in an inspection optical path through a coordinate system conversion method;and the angular eccentricity and linear eccentricity of the aspheric optical axis and the mechanical reference axis thereof are calculated. High-precision centering measurement of the large-apertureconcave aspheric surface is completed.

Description

technical field [0001] The invention relates to a centering system and method for a large-diameter concave aspheric surface. The system and method are mainly applied to the centering of the main reflector of a large-diameter optical remote sensor lens with a coaxial design, and can improve the optical axis of the main reflector. The invention relates to the accuracy of centering measurement relative to its structural reference, and belongs to the technical field of space optics assembly and adjustment testing. Background technique [0002] With the increasing resolution of remote sensors for earth observation, coaxial total reflection optical systems with large aperture and long focal length have been frequently used in the design of remote sensors in recent years. The base of the coaxial total reflection optical system with large aperture and long focal length is the main reflector, which is generally a concave aspheric surface, and its reflecting surface is a quadratic or ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M11/02

CPCG01M11/02G01M11/0221

Inventor 陈佳夷李斌王聪王海超霍腾飞王昀栗孟娟于宗伟王向东冀翼

Owner BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com