Method for designing bionic structure of vehicle roof cover reinforcing rib

A technology of structural design and roof cover, applied in design optimization/simulation, instrumentation, electrical digital data processing, etc., can solve problems such as single cross-section shape, conservative rib structure design, etc., and achieve the effect of improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

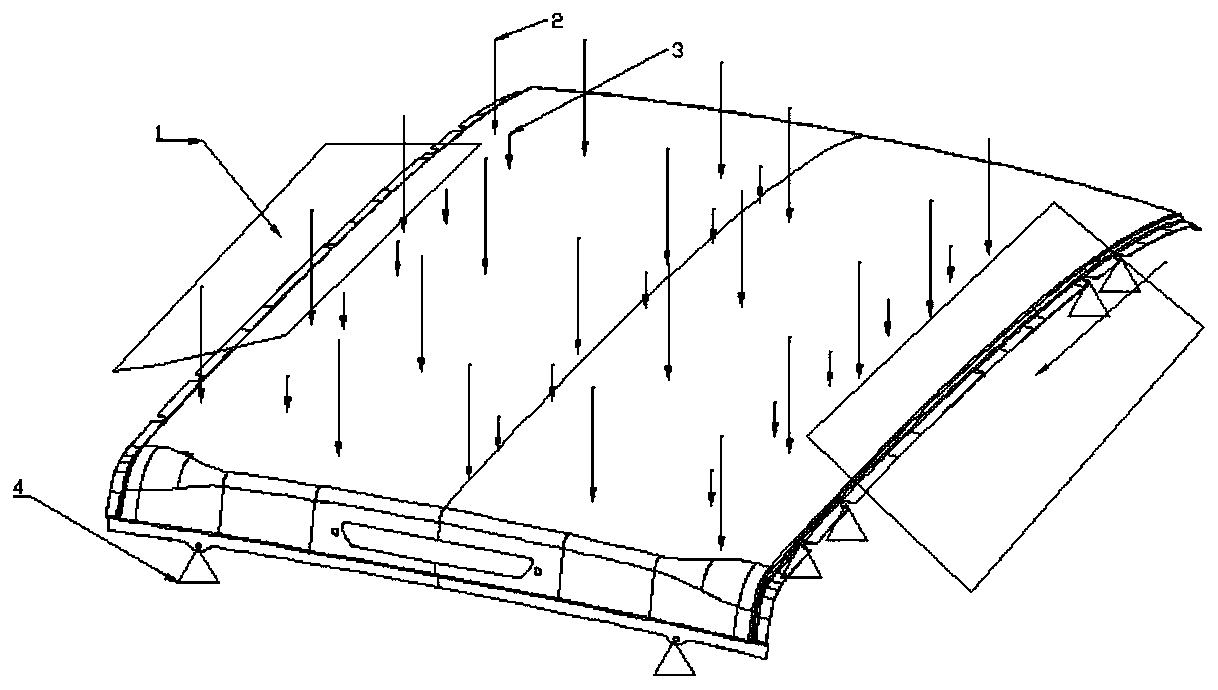

[0027] Such as figure 1 As shown in Fig. 1, the 3D structural modeling of the roof of the car is carried out, and the mid-surface is extracted, the geometry is cleaned and the mesh is divided to obtain the finite element model of the roof.

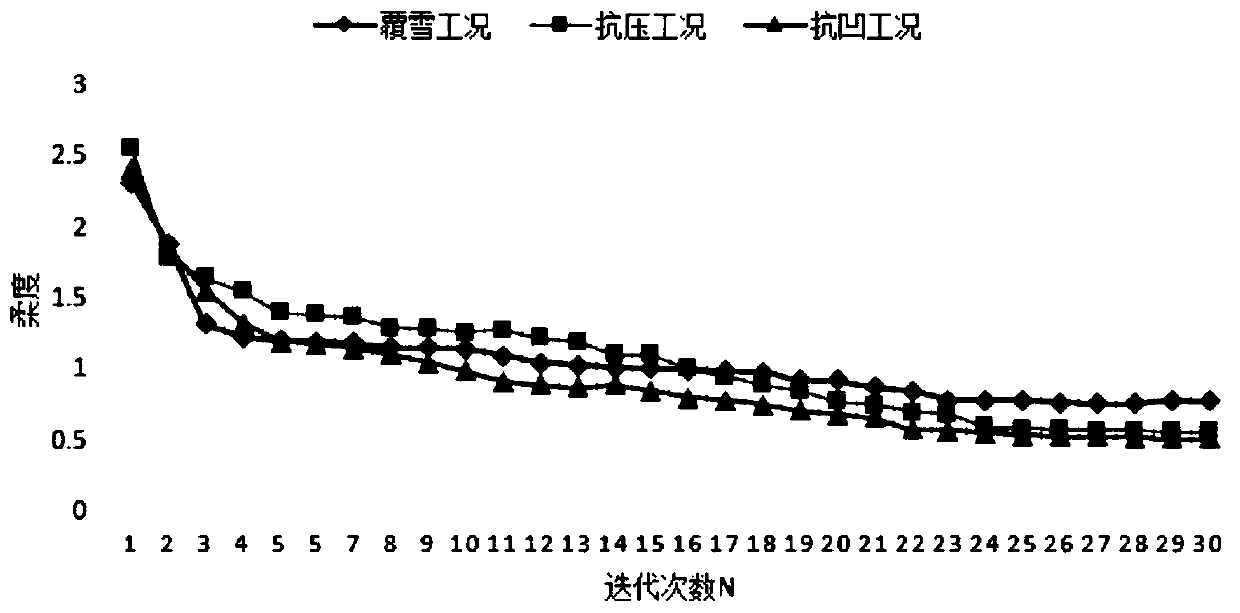

[0028] Such as figure 2 As shown, the snow crushing resistance, compression resistance and dent resistance performance of the finite element model of the roof cover were calculated and analyzed respectively. Six degrees of freedom are fully constrained around the connection between the roof and the frame; for the anti-snow crushing performance, the roof is loaded with a uniform load, the direction is vertically downward, and the snow pressure thickness is 90mm and 160mm respectively. The snow thickness formula is:

[0029] Therefore, for the loading methods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com