Method for calculating temperature field of laser ablation carbon fiber target material

A technology of laser ablation and calculation method, which is applied in calculation, computer-aided design, design optimization/simulation, etc., can solve the problem of not considering the thermal physical properties of the element sequence stripped carbon fiber target, inaccurate calculation of burn-through time, carbon fiber temperature field, etc. Problems such as low distribution accuracy can achieve the effect of avoiding abnormal temperature, reducing error and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

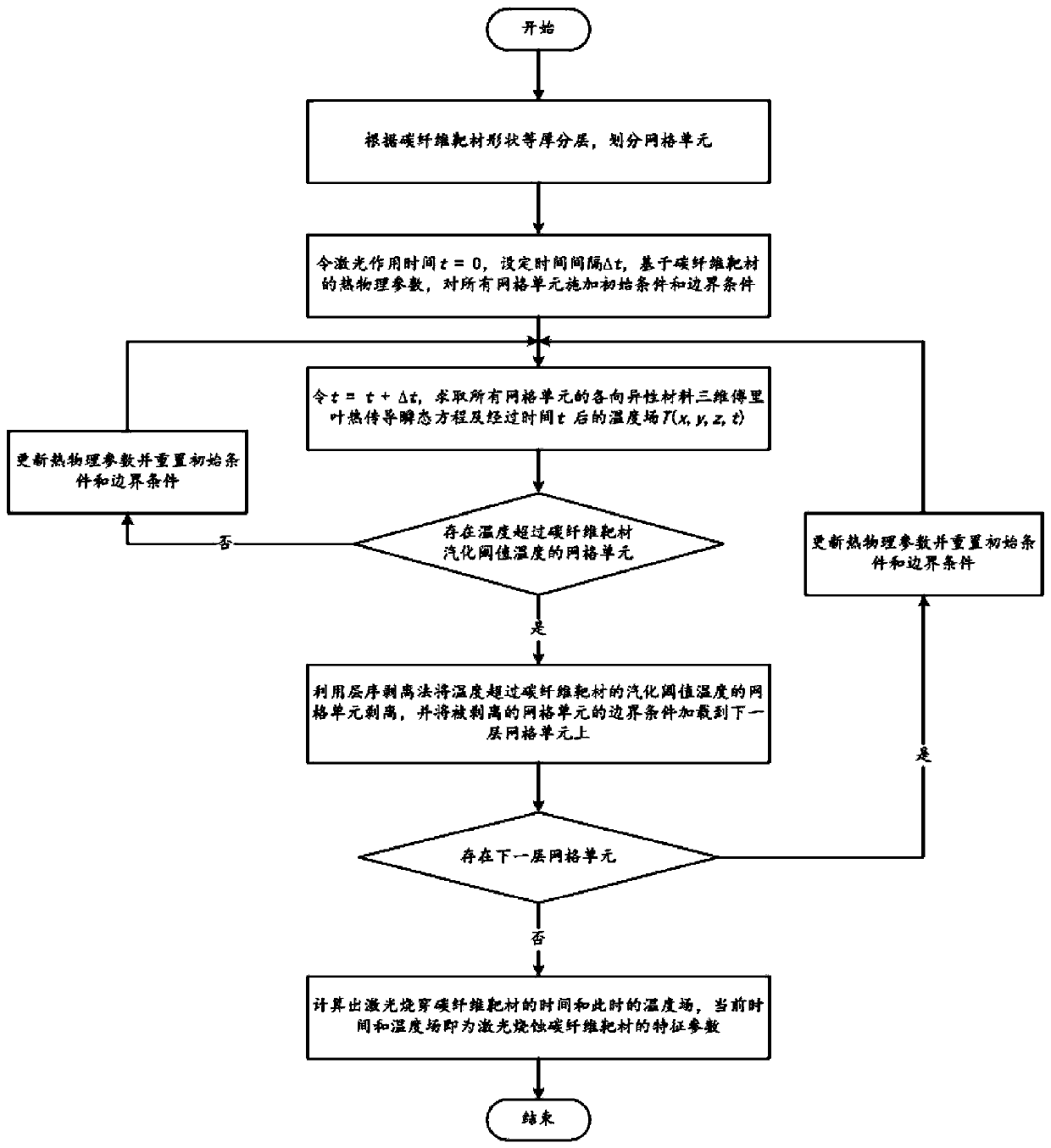

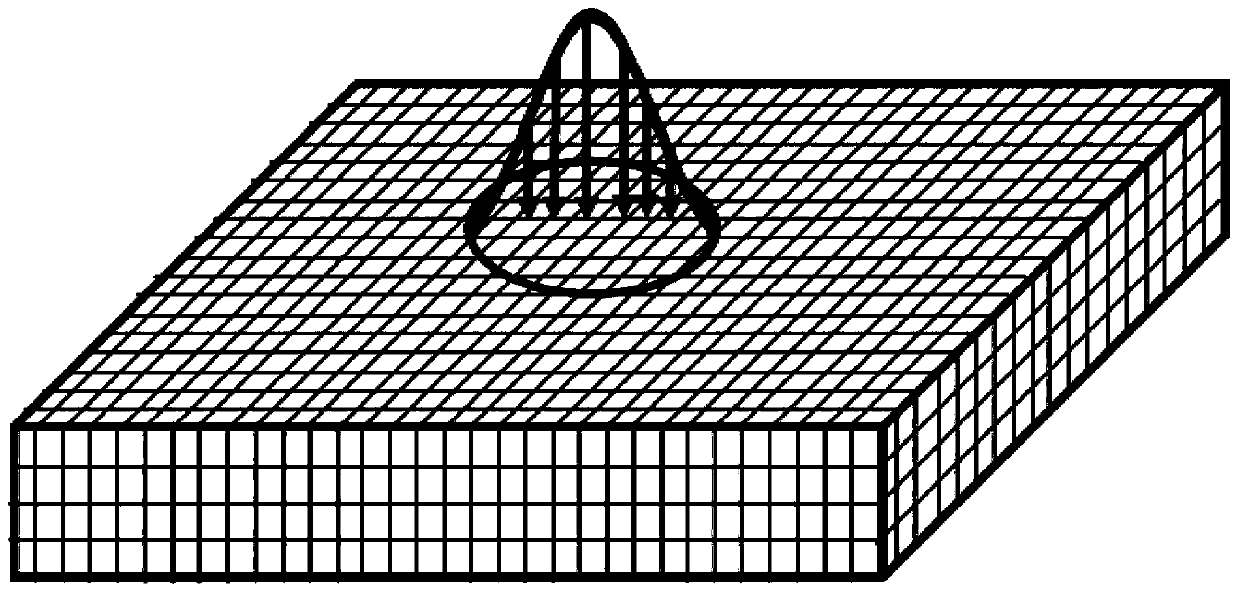

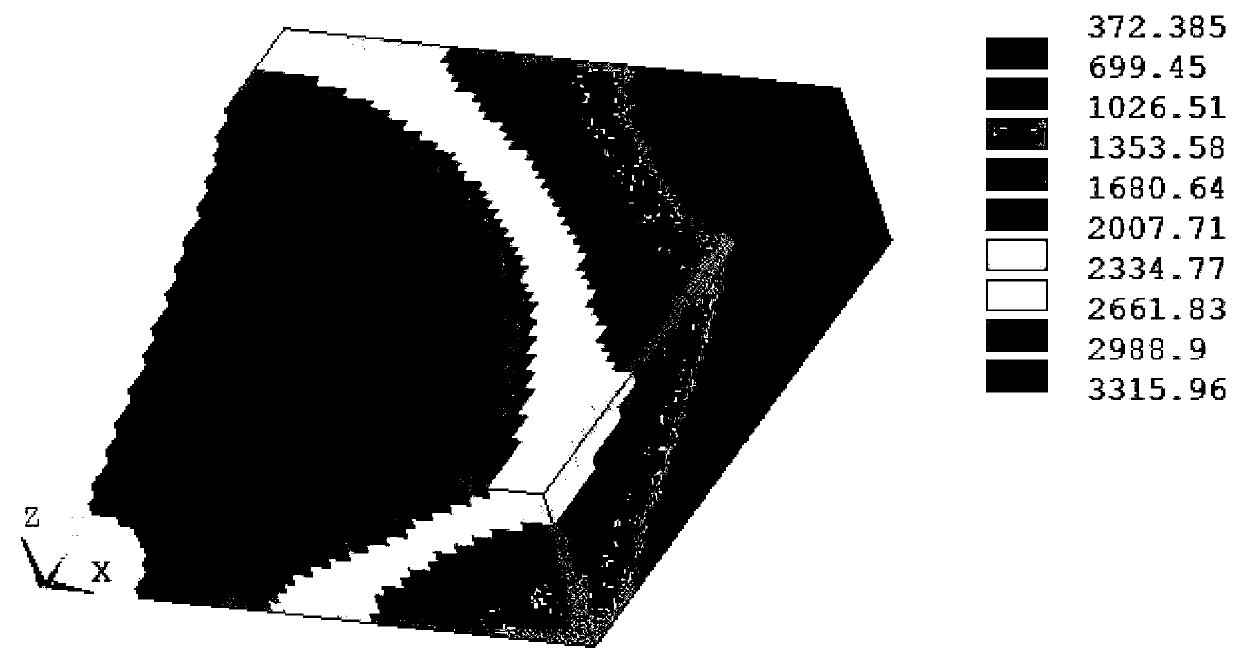

[0055] In the prior art, when calculating the temperature field and burn-through time of laser ablation carbon fiber targets, the carbon fiber material is usually regarded as an isotropic medium, and its thermophysical parameters are also treated as constants. During the calculation process, the two-dimensional The temperature field is rotated to directly obtain the three-dimensional temperature field, ignoring the fact that the surface of the carbon fiber target is peeled off, resulting in a large error in the calculation of the temperature field and burn-through time of the carbon fiber target. The inventors of the present application found in the research: (1) the thermal physical parameters of the carbon fiber target should not be treated as constants, but should be regarded as values that vary with temperature; (2) for the laser ablation process The unit whose surface temperature of the carbon fiber target exceeds the temperature threshold should be peeled off. In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com