Method and device for automatically checking pressing plate

A technology of automatic calibration and pressing, which is applied in image data processing, instrument, character and pattern recognition, etc., to achieve the effect of improving efficiency, strong reproducibility and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

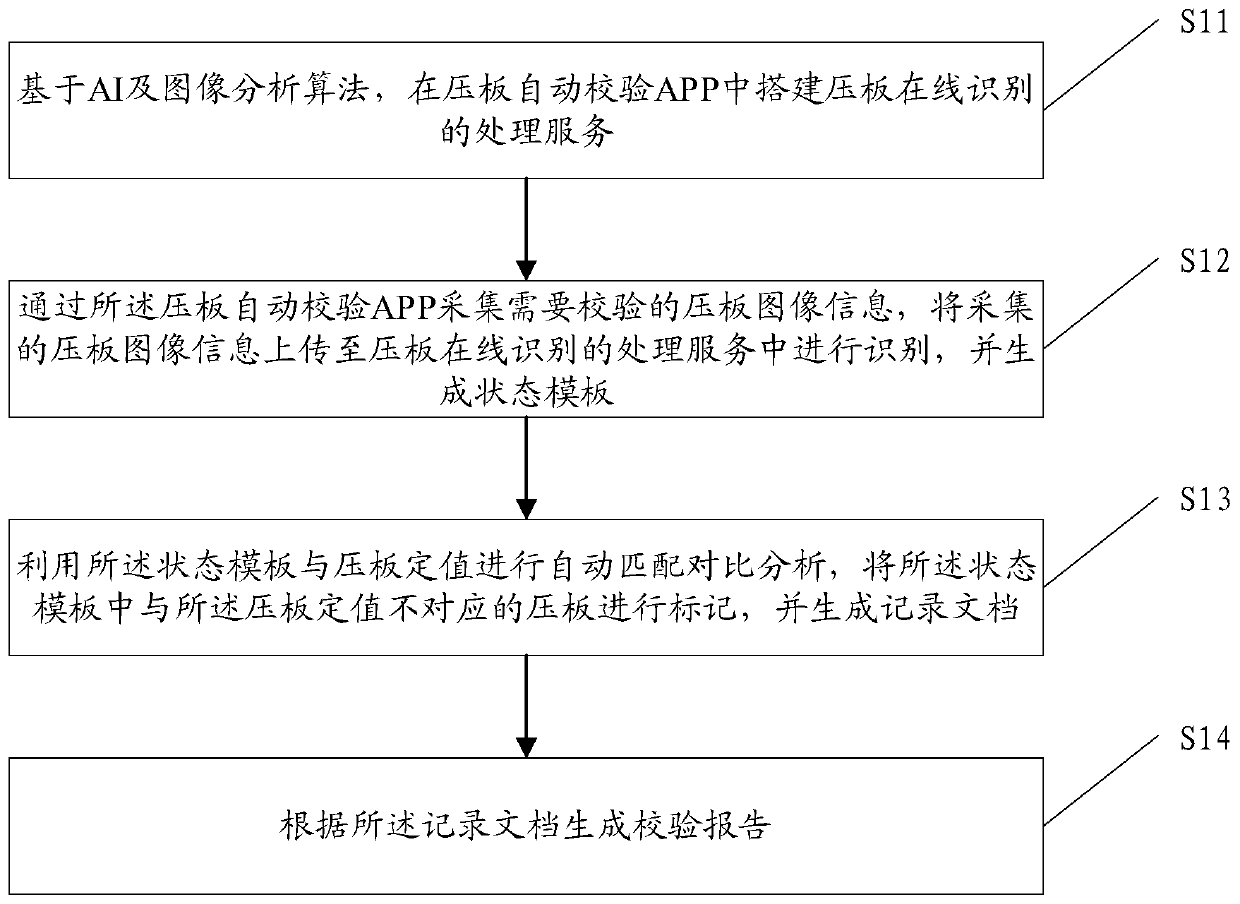

[0037] see figure 1 , figure 1 It is a schematic flow chart of a method for automatic verification of the pressing plate in the implementation of the present invention.

[0038] like figure 1 Shown, a kind of method for platen automatic verification, described method comprises:

[0039] S11: Based on AI and image analysis algorithms, build a processing service for online platen recognition in the platen automatic verification APP;

[0040] Specifically, the AI (Artificial Intelligence) refers to artificial intelligence. The fields of AI technology research include language processing, image recognition, and language recognition. The automatic verification APP of the pressure plate mainly adopts the technology of image recognition in AI technology. Video coding technology based on MPEG series is the mainstream direction of video codec technology development at present. This kind of MPEG series compression technology is commonly used in the remote viewing system running on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com