Photovoltaic panel frame and assembly equipment thereof

A technology for assembling equipment and photovoltaic panels, applied in assembly machines, photovoltaic power generation, photovoltaic modules, etc., can solve problems such as low installation efficiency, manual installation, and damage to photovoltaic panels, and achieve the effect of improving assembly efficiency and reducing the probability of collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

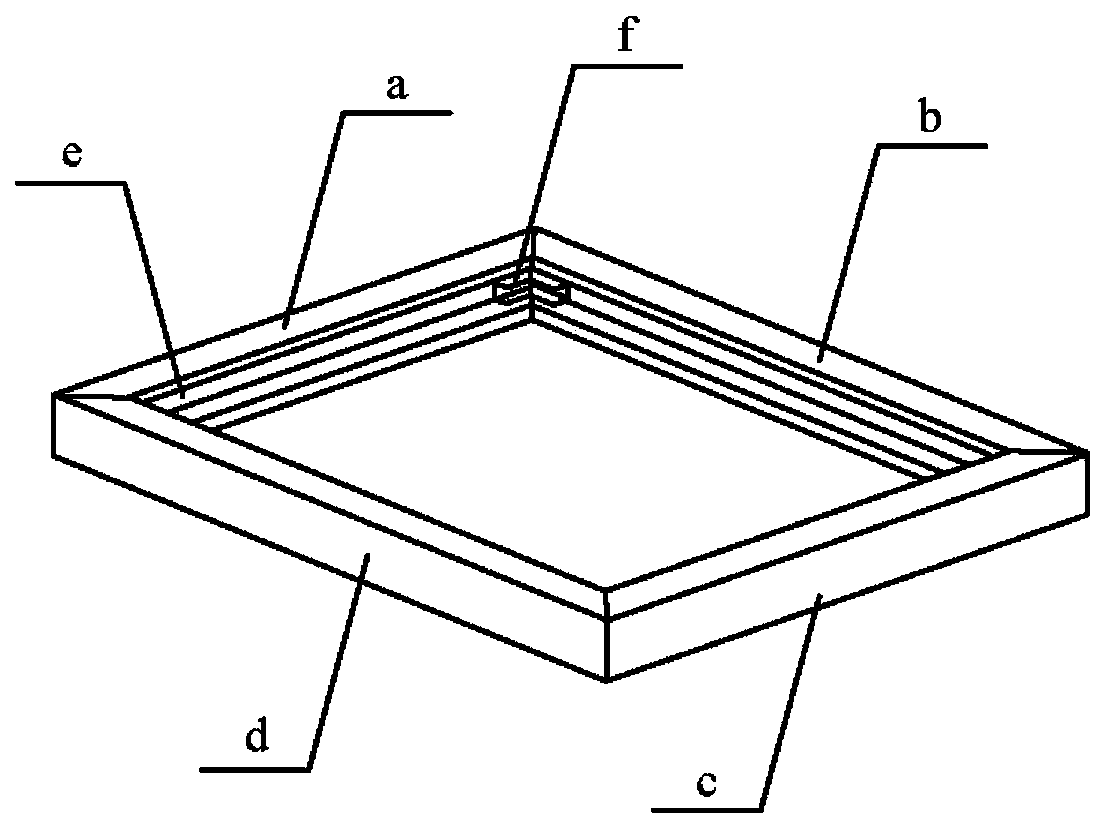

[0025] Such as Figure 1-4 As shown, the present invention provides a technical solution: a photovoltaic panel frame includes frame a, frame b, frame c, frame d, slot e and corner connector f, the frame a, frame b, frame c and Frame d is set to the same shape, both ends are set to a 45° inclination angle, and is made of aluminum alloy; the slot e is set on the inside of frame a, frame b, frame c and frame d; the described The connector f is set in an "L" shape and is made of rubber material. The corner connector f can connect frame a, frame b, frame c and frame d into a square frame. Protect.

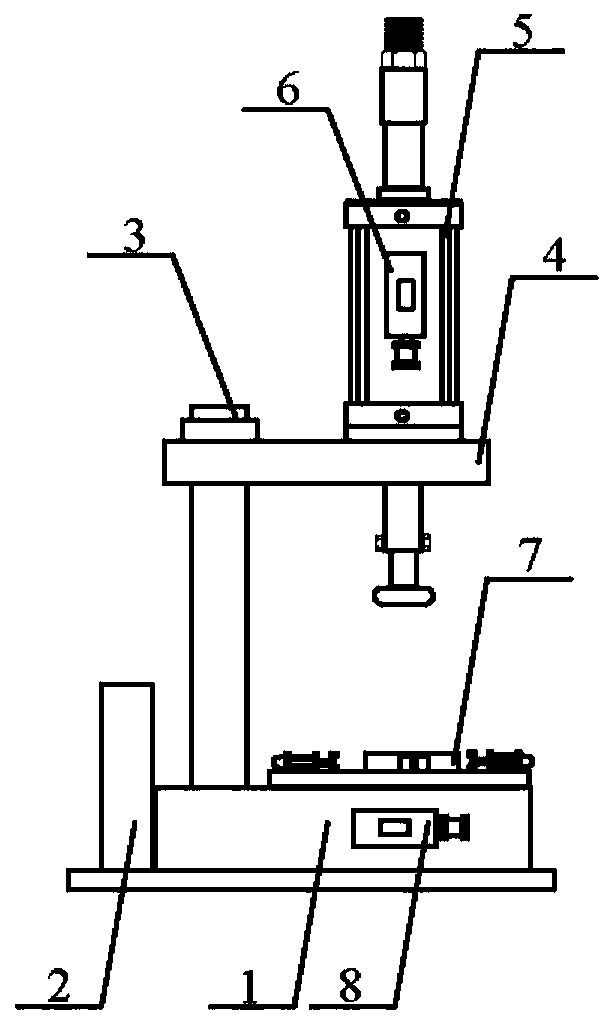

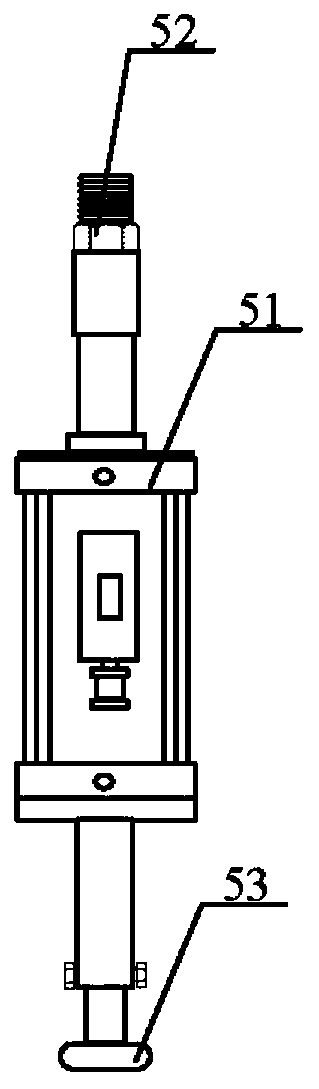

[0026] A photovoltaic panel frame assembly equipment includes a machine base 1, an air control cabinet 2, a column 3, a top seat 4, a clamping mechanism 5, a first pneumatic solenoid valve 6, an assembly mechanism 7 and a second air control solenoid valve 8, the The air control cabinet 2 is installed on one side of the base 1 through bolts, and the air control cabinet 2 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com