Adapter ring of industrial camera lens and CCD and control method

An industrial camera and control method technology, which is applied to color TV parts, TV system parts, TVs, etc., can solve the problems of inability to perform remote control, separate power supply for the adapter ring, and configuration requirements, etc., to reduce conversion , reduce equipment and intermediate operations, and avoid the effect of complex wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

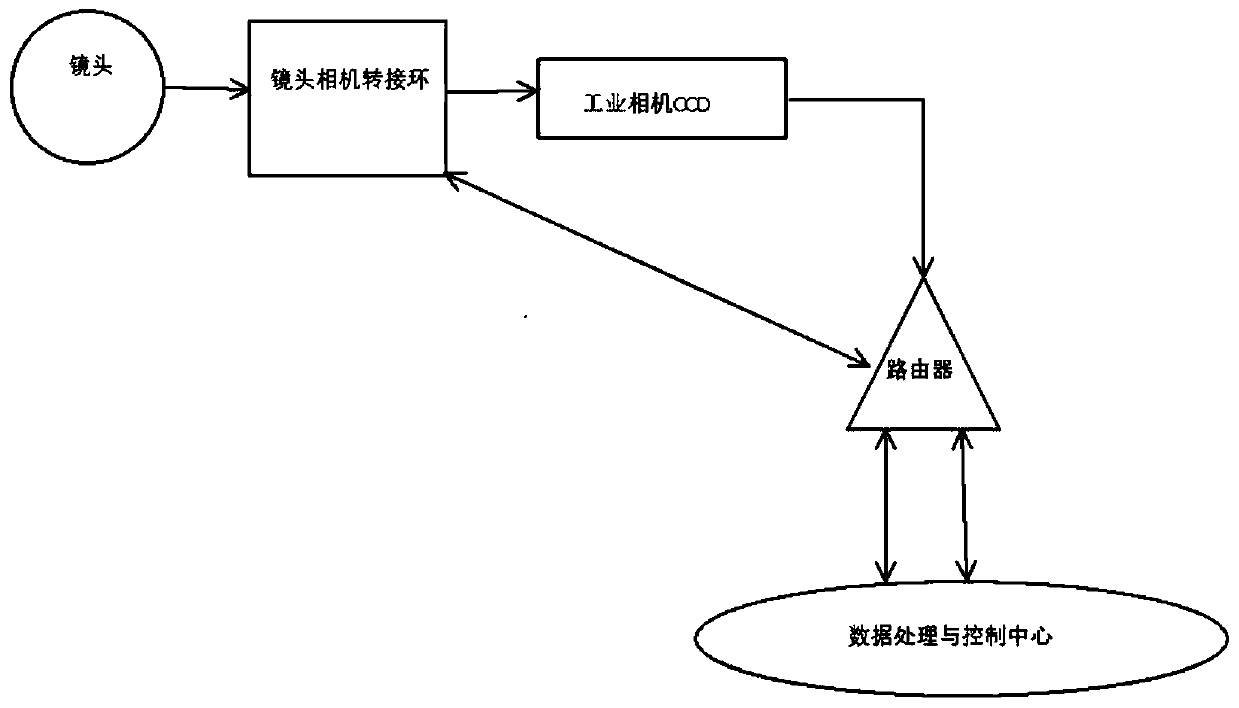

[0054] see figure 1 , an adapter ring for an industrial camera lens and a CCD, the adapter ring is respectively connected to the lens and the CCD through a mechanical bayonet, and both sides of the adapter ring are provided with bayonet sockets for respectively snapping the lens and the CCD .

[0055] At the same time, the adapter ring is connected to the router through the network port, and the router is further connected (including wired connection and wireless connection) to the control device through the network port.

[0056] The control device is used for data processing and switching ring control.

[0057] The control device utilizes a router to obtain data and control the lens through industrial Ethernet.

[0058] The adapter ring provides power through the POE power supply of the router, so as to omit a separate power supply connector.

[0059] Preferably, a lens control protocol is integrated in the adapter ring to realize control of the lens.

[0060] Further, a...

Embodiment 2

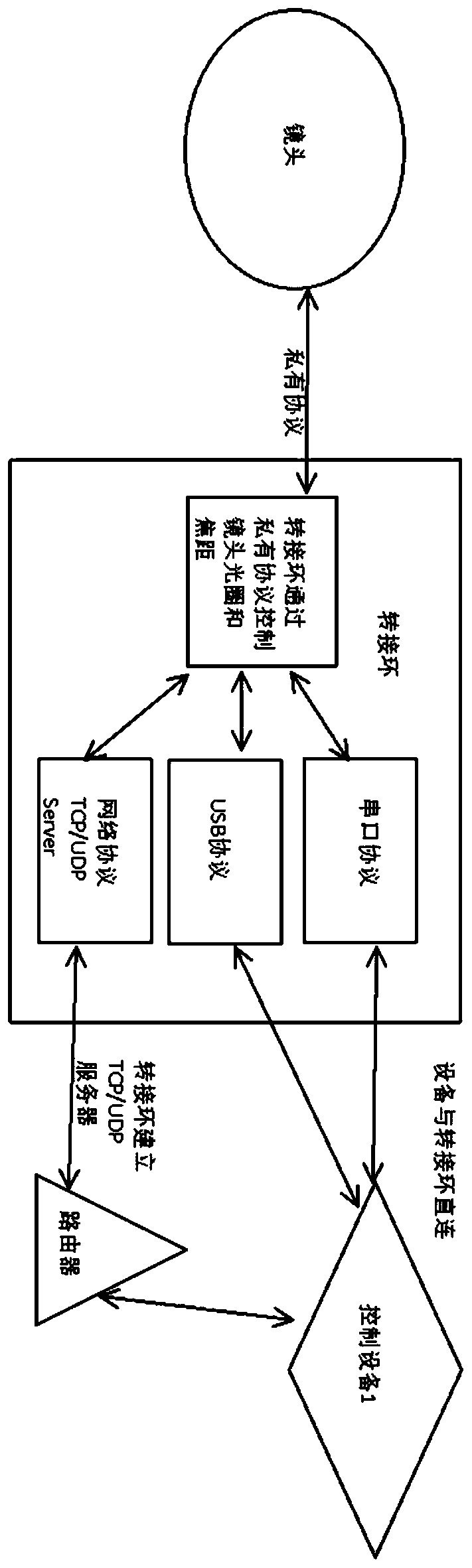

[0068] On the basis of Embodiment 1, this embodiment further proposes a control method for an adapter ring between an industrial camera lens and a CCD. see figure 2 , the control method is specifically:

[0069] (1) Use an adapter ring to connect the lens and the industrial camera CCD respectively.

[0070] (2) After power-on, the micro control unit bootloader (MCU Bootloader) guides the adapter ring program to start.

[0071] (3) The adapter ring monitors the connection signal with the lens, and sends a command to detect whether the lens exists and is in a working state;

[0072] If the lens is in working condition, send a command to obtain lens parameters, including model, lens focal length range, lens aperture range and other information.

[0073] (4) According to the lens model, load the library file of the corresponding lens, so that the adapter ring can correctly control the movement of the lens, and can obtain the position status information of the lens.

[0074] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com