Constant temperature welding laser controller

A controller and laser technology, used in welding equipment, laser welding equipment, manufacturing tools, etc., to achieve the effects of strong anti-interference ability, large-scale and high-precision temperature detection, and flexible calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

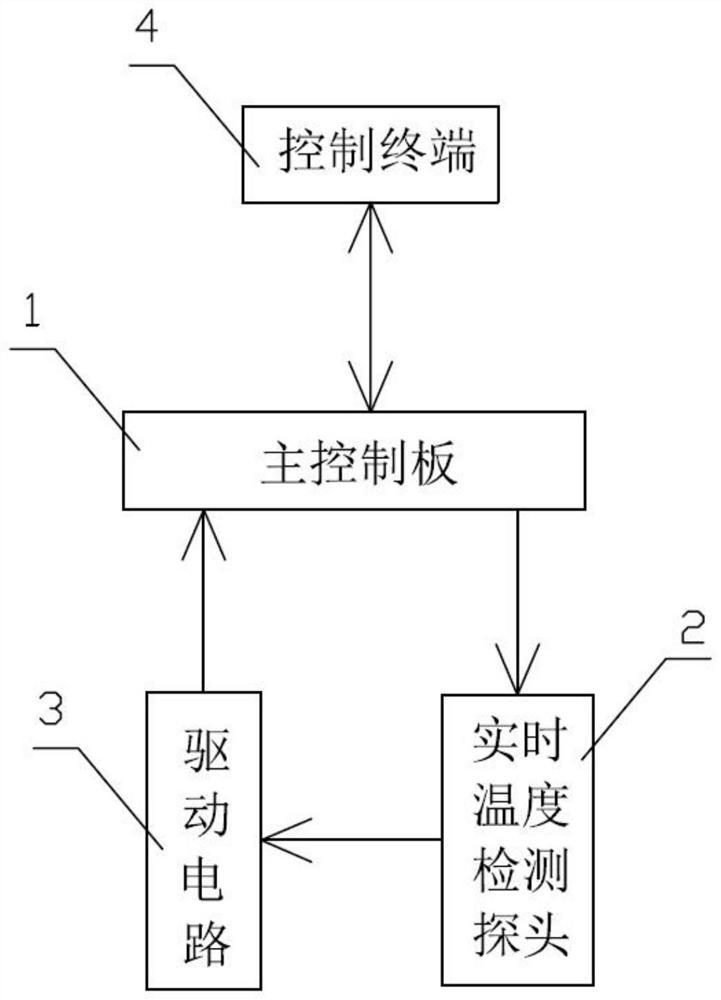

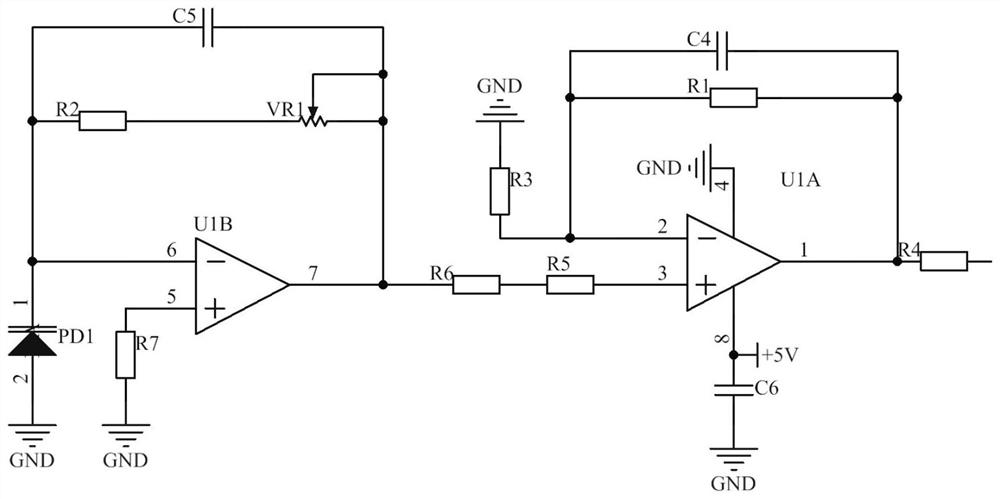

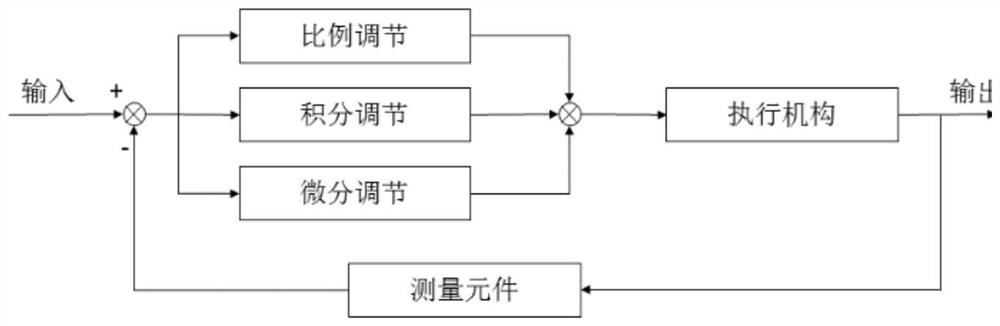

[0017] combined with figure 1 to attach Figure 4 , the invention discloses a constant temperature welding laser controller, the controller and the laser controlled by it are split structure; it includes a main control board 1 and a real-time temperature detection probe 2; the main control The board 1 is used to combine the real-time temperature information, and output the laser power adjustment signal to the laser after the precise algorithm operation carried in the microprocessor; the real-time temperature detection probe 2 is used to realize the non-contact real-time temperature detection of the welding point , the real-time temperature detection probe 2 is a photodiode, and the photodiode is connected with a drive circuit 3; the drive circuit 3 is connected with the control center signal on the main control board 1, and the drive circuit 3 is used to det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com