Water spraying device for milling based on precision numerical control machine tool

A water spraying device and milling technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of moving distances, reducing cooling effects, and unpredictable position cooling, etc., to achieve safe use. Convenience, improve cooling effect, avoid dead angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

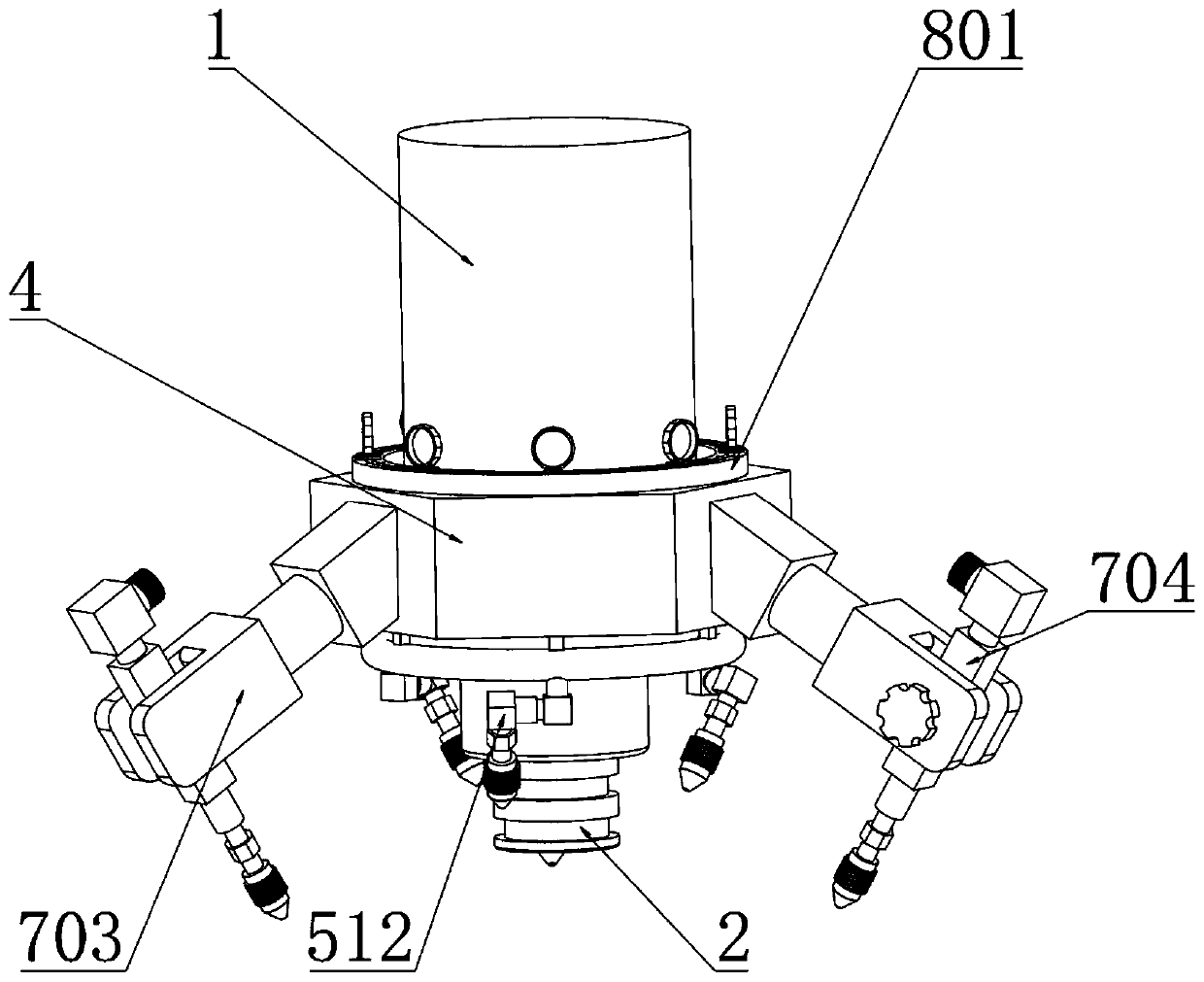

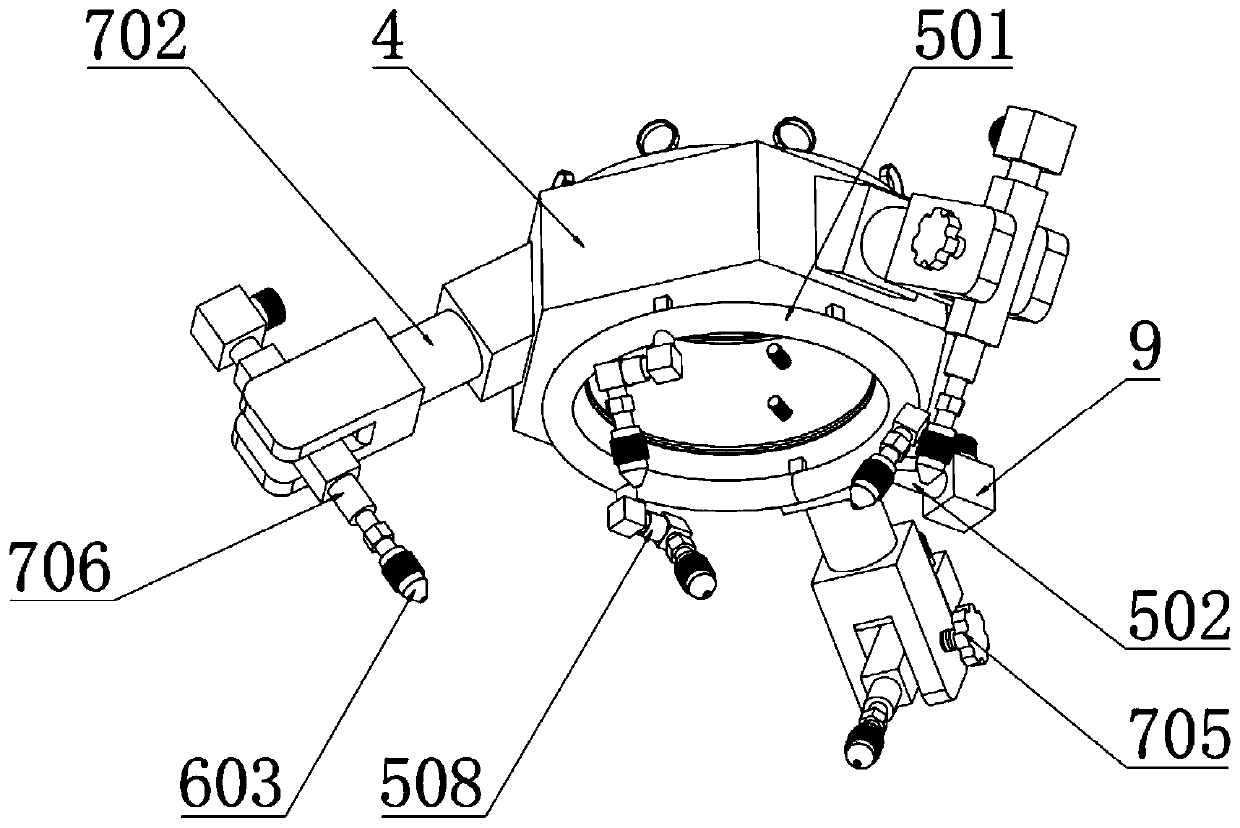

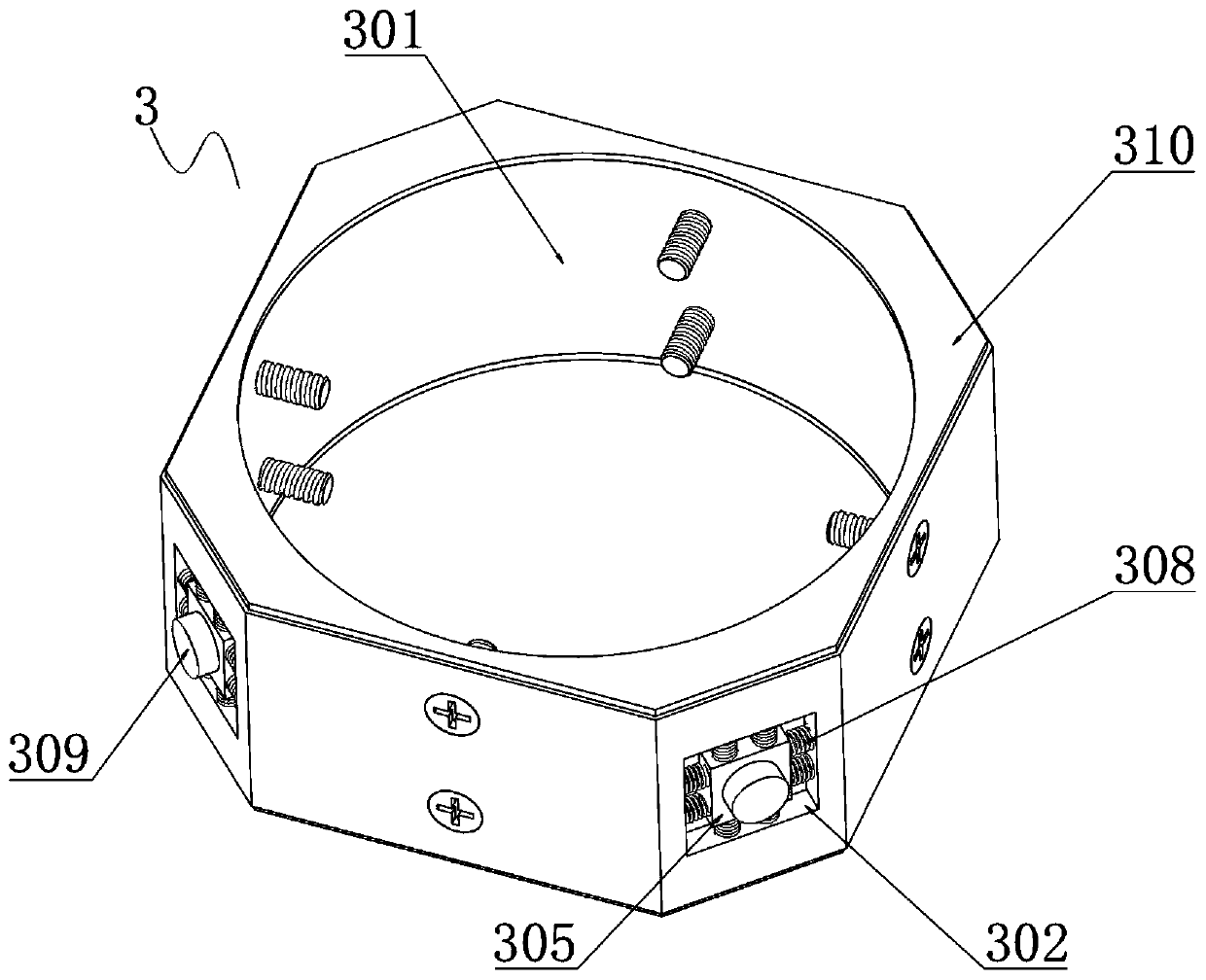

[0051] Example: such as Figure 1-9 As shown, the present invention provides a kind of technical scheme, a kind of water spraying device based on the milling processing of precision numerical control machine tool, comprising:

[0052] The shock absorbing mechanism 3 is used to buffer the vibration of the water spray device to prevent the water spray device from shaking during the processing and prevent the coolant from being sprayed to the correct position;

[0053] The tool cooling mechanism 5 is used to cool the cutting tool to prevent the cutting tool from being overheated and affecting the machining accuracy;

[0054] The water spray mechanism 6 is used to maintain the speed at which the coolant is sprayed, so that the coolant can be accurately sprayed to the cooling position;

[0055] The workpiece cooling mechanism 7 is used to cool the workpiece in processing and flush the chips on the surface of the workpiece at the same time;

[0056] The pipeline arrangement mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com