Ceramic tile cutting device

A technology for cutting equipment and ceramic tiles, which is applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc. It can solve the problems of cumbersome manual feeding operations, inaccurate feeding, and low safety, so as to improve cutting efficiency, Ease of operation and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

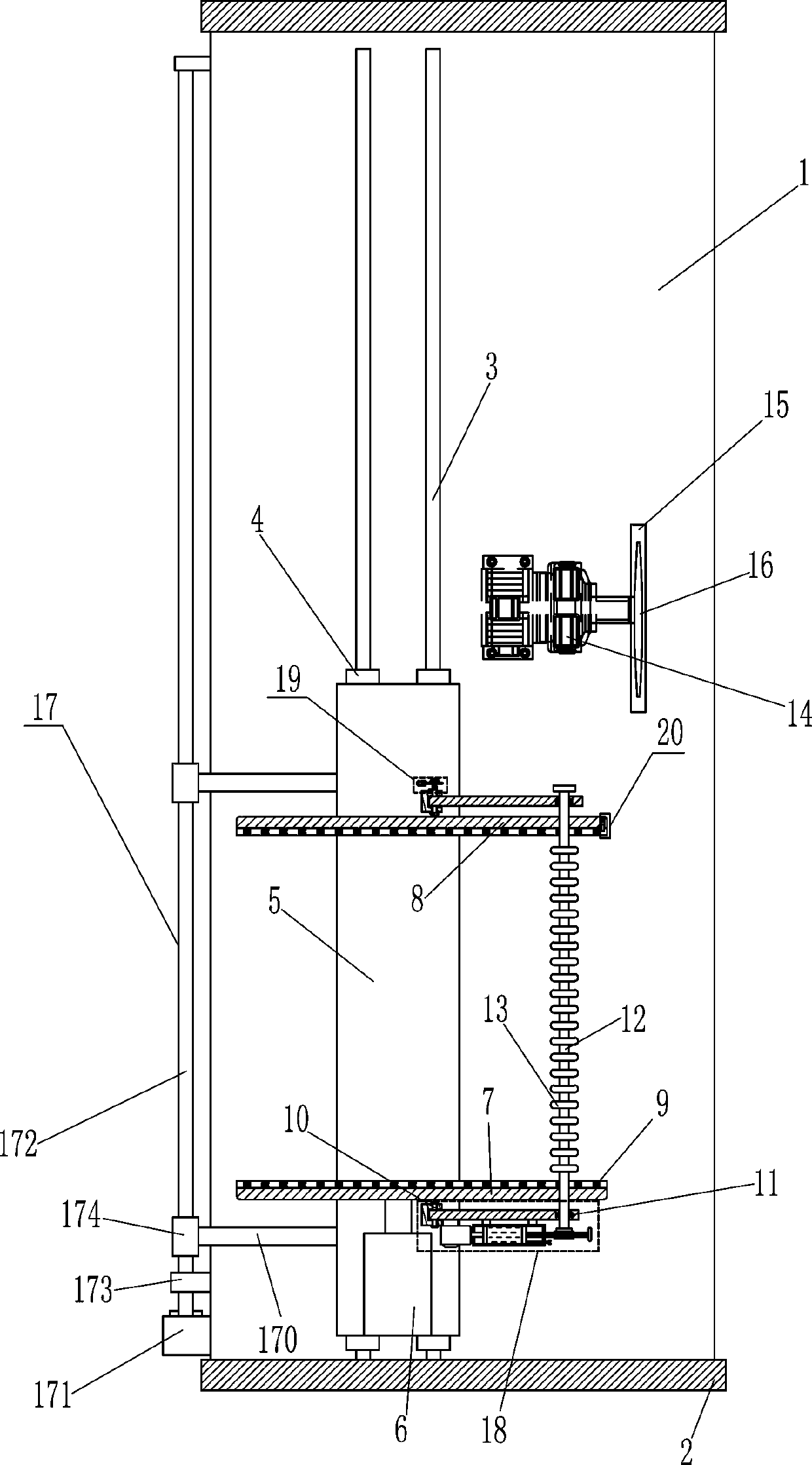

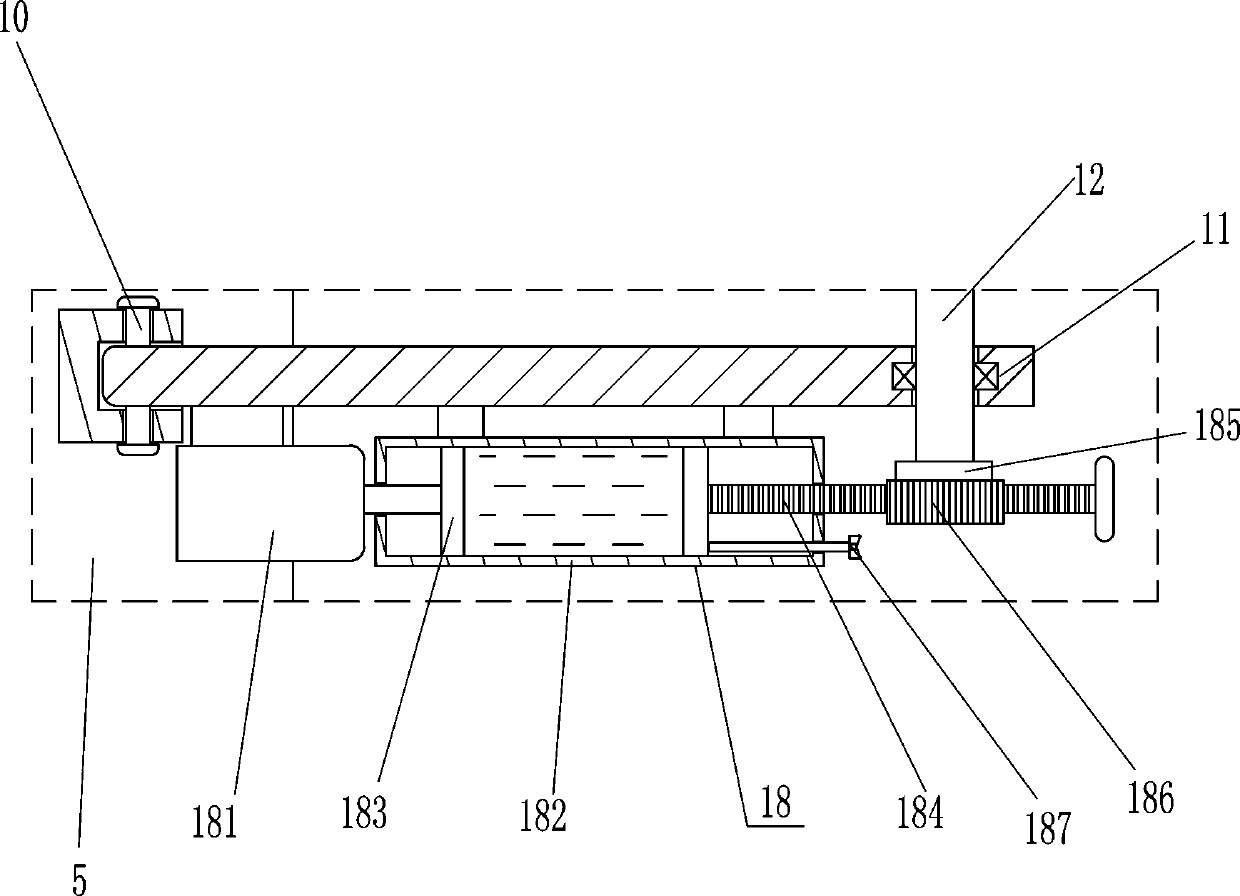

[0017] A tile cutting equipment such as figure 1 As shown, it includes a bottom plate 1, a baffle plate 2, a slide rail 3, a first slider 4, a mounting seat 5, a first cylinder 6, a moving deck 7, a fixed deck 8, a pulley 9, a rotating shaft 10, and a torsion spring 101 , swing bar 11, transmission rod 12, rubber roller 13, first motor 14, emery wheel 16 and driving mechanism 17, base plate 1 front and rear sides are connected with baffle plate 2, base plate 1 is connected with baffle plate 2 by the mode of welding connection, base plate 1 The left side of the top is symmetrically provided with a slide rail 3, the slide rail 3 is provided with a first slider 4, the top of the first slider 4 on the left and right sides is connected with a mounting seat 5, and the top front side of the mounting seat 5 is provided with a first cylinder 6 , the telescopic rod of the first cylinder 6 is connected with a movable deck 7, and the rear side of the top of the mounting base 5 is provided...

Embodiment 2

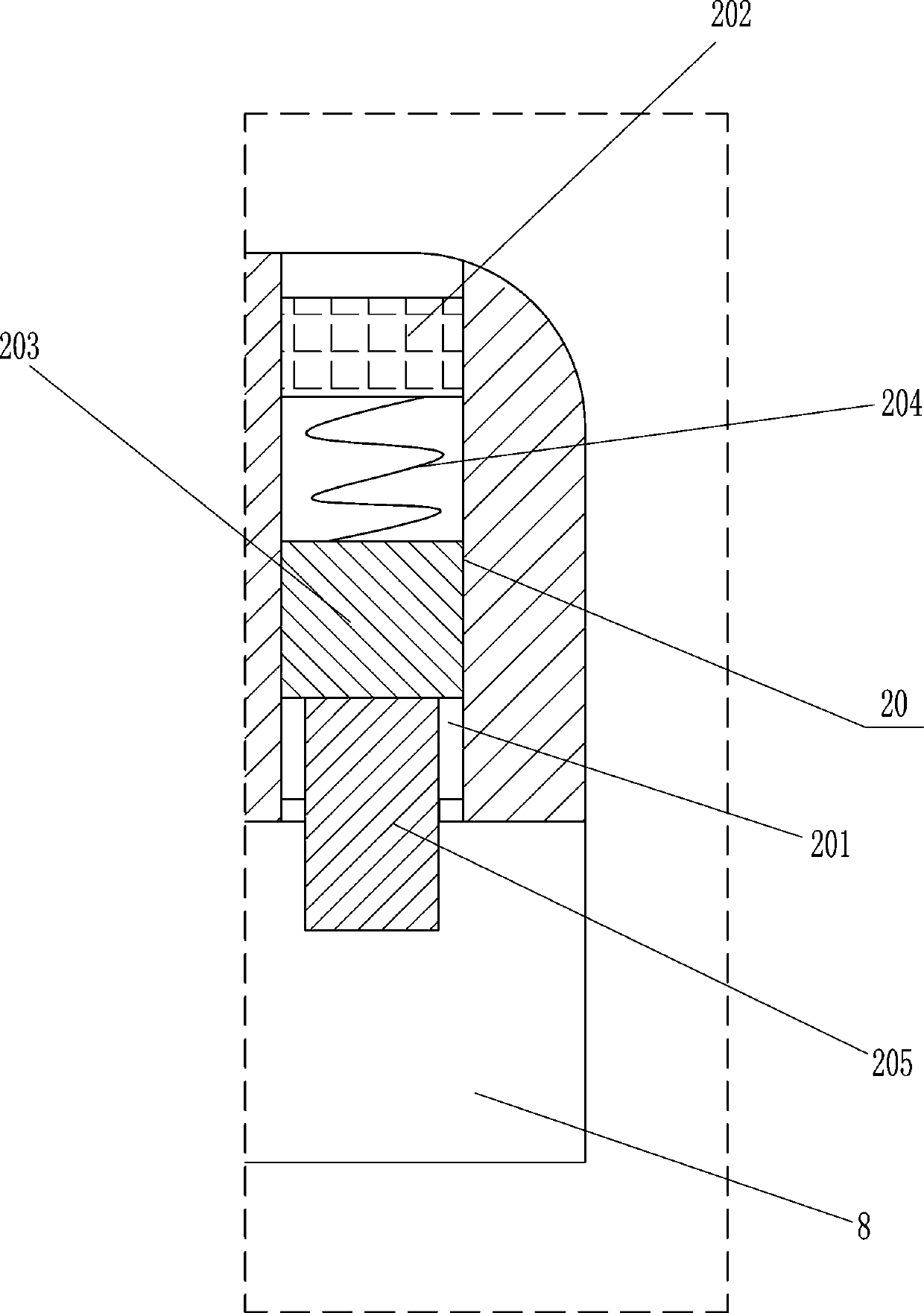

[0019] A tile cutting equipment such as figure 1 As shown, it includes a bottom plate 1, a baffle plate 2, a slide rail 3, a first slider 4, a mounting seat 5, a first cylinder 6, a moving deck 7, a fixed deck 8, a pulley 9, a rotating shaft 10, and a torsion spring 101 , swing bar 11, transmission rod 12, rubber roller 13, first motor 14, emery wheel 16 and driving mechanism 17, base plate 1 front and rear sides are connected with baffle plate 2, base plate 1 top left side is symmetrically provided with slide rail 3, slide rail 3 is provided with a first slider 4, the top of the first slider 4 on the left and right sides is connected with a mounting seat 5, and the front side of the top of the mounting seat 5 is provided with a first cylinder 6, and the telescopic rod of the first cylinder 6 is connected with a mobile card seat 7. There is a fixed deck 8 on the rear side of the top of the mounting base 5, and a plurality of pulleys 9 are provided on the inner bottom of the mo...

Embodiment 3

[0022] A tile cutting equipment such as Figure 1-2As shown, it includes a bottom plate 1, a baffle plate 2, a slide rail 3, a first slider 4, a mounting seat 5, a first cylinder 6, a moving deck 7, a fixed deck 8, a pulley 9, a rotating shaft 10, and a torsion spring 101 , swing bar 11, transmission rod 12, rubber roller 13, first motor 14, emery wheel 16 and driving mechanism 17, base plate 1 front and rear sides are connected with baffle plate 2, base plate 1 top left side is symmetrically provided with slide rail 3, slide rail 3 is provided with a first slider 4, the top of the first slider 4 on the left and right sides is connected with a mounting seat 5, and the front side of the top of the mounting seat 5 is provided with a first cylinder 6, and the telescopic rod of the first cylinder 6 is connected with a mobile card seat 7. There is a fixed deck 8 on the rear side of the top of the mounting base 5, and a plurality of pulleys 9 are provided on the inner bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com