Sectional type bin body capable of achieving continuous high-pressure feeding of powder and using method thereof

A segmented, powder material technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of powder medicines that cannot be measured, adjusted and controlled, and cannot work continuously and normally, so as to improve construction efficiency and replace inaccuracy. Sexuality, the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] When the dry spraying method is used for the construction of the mixing pile, a segmented bin body that can realize continuous high-pressure feeding of the powder according to the present invention is used for construction. The parameters of the mixing pile are: the mixing amount of the curing agent is 25%, and the pile The diameter is 800mm, and the pile length is 30m. The specific construction steps are as follows:

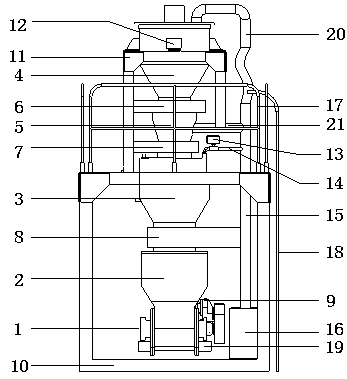

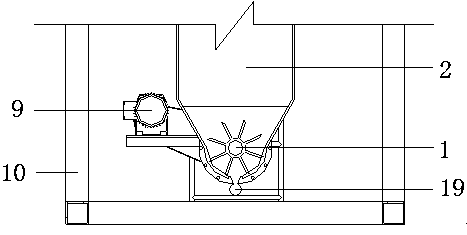

[0036] Such as Figure 1-2As shown, a segmented bin that can realize continuous high-pressure feeding of powder is characterized in that it includes a rotary feeder 1, a feeding funnel 2, an intermediate hopper 3, a metering funnel 4, an exhaust chamber 5, a valve module, Motor 9, base bracket 10, upper bracket 11, mass meter 12, ball valve 13, connecting pipe 14, exhaust pipe 15, dust removal box 16, guardrail 17, ladder 18, powder passage 19, flexible conduit 20, pressure relief pipe 21. The valve module includes No. 1 valve 6, No. 2 valve 7, and No. ...

Embodiment 2

[0059] When using powder medicament to restore the soil of the polluted site, a segmented bin body that can realize powder continuous high-pressure feeding according to the present invention is used for construction, and the dosage of medicament is 1%. The specific construction steps are as follows:

[0060] Such as Figure 1-2 As shown, a segmented bin that can realize continuous high-pressure feeding of powder is characterized in that it includes a rotary feeder 1, a feeding funnel 2, an intermediate hopper 3, a metering funnel 4, an exhaust chamber 5, a valve module, Motor 9, base bracket 10, upper bracket 11, mass meter 12, ball valve 13, connecting pipe 14, exhaust pipe 15, dust removal box 16, guardrail 17, ladder 18, powder passage 19, flexible conduit 20, pressure relief pipe 21. The valve module includes No. 1 valve 6, No. 2 valve 7, and No. 3 valve 8; the base bracket 10 and the upper bracket 11 are welded by square steel, and the bottom bracket and the upper bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com