Automatic water quality monitoring and dosing system for circulating cooling water of diesel engine

A circulating cooling water and automatic monitoring technology, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of adding anti-rust maintenance agents and not being able to grasp water quality changes in time , to achieve the effect of facilitating data processing, improving sensitivity and reliability, and convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

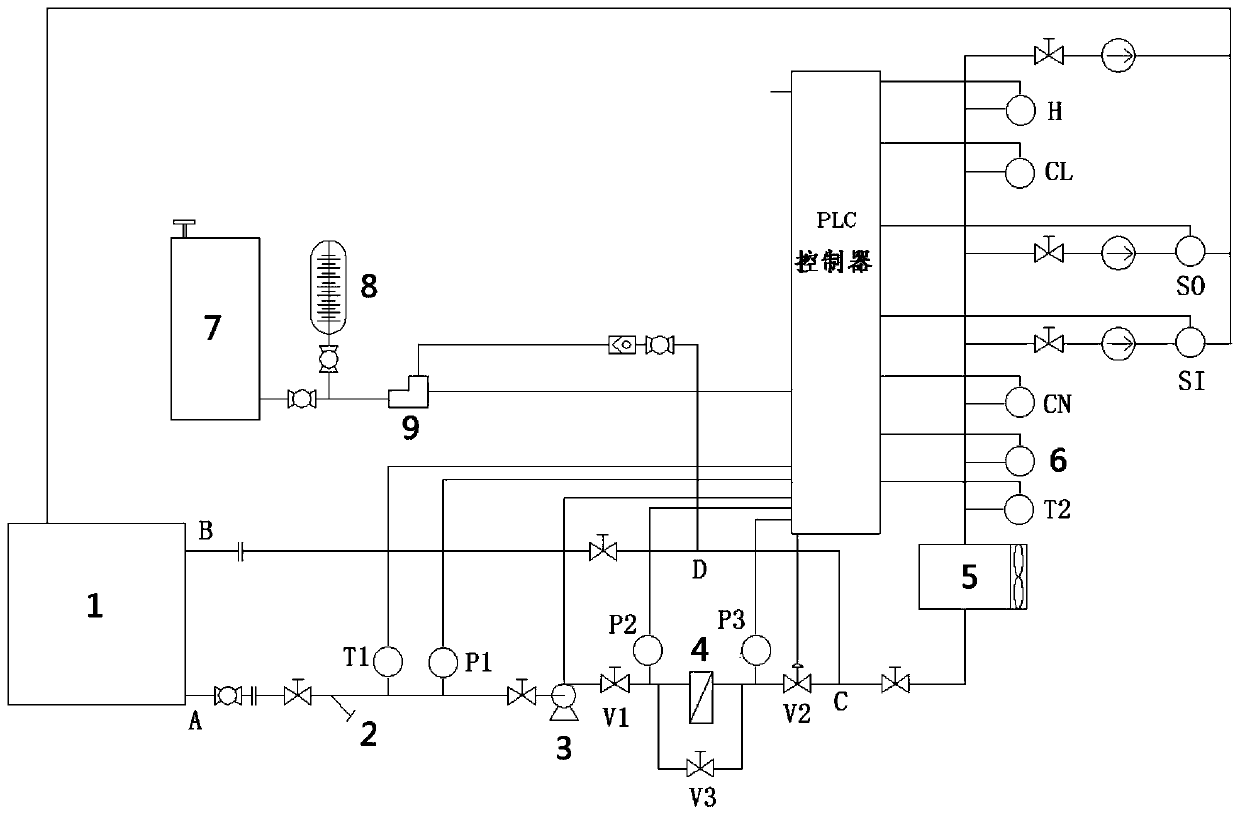

[0037] The water quality automatic monitoring and dosing system of diesel engine circulating cooling water of the present invention, see figure 1 , including a circulating filtration circuit, a water quality monitoring circuit, a dosing device and an automatic control display device; these four components realize the integrated structure of the skid to facilitate the transfer and transportation of the device. Now respectively explain as follows.

[0038] 1. The circulation filtration circuit is used to filter and purify the circulation cooling water, including the water tank 1, the water inlet filter 2, the circulation pump 3 and the filter bag filter 4.

[0039]The water tank 1 is used to store cooling water, and is provided with a water outlet A and a water return port B. In order to distribute the added medicament evenly in the water tank 1, the water outlet A and the water return port B should be located on both sides of the water tank 1. The relative position of the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com