Sewer well lid and well lid assembly

A technology for sewers and manhole covers, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve time-consuming and labor-intensive problems, and achieve the effects of avoiding pipe burst accidents, improving safety, and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a sewer manhole cover, comprising the following raw materials in parts by weight: 7-9 parts of styrene, 6-8 parts of polystyrene, 60-80 parts of 109 resin, 90-110 parts of stone powder, 0.03-0.05 parts Calcium hydroxide, 1.5-2 parts of zinc stearate, 0.015-0.02 parts of tert-butyl ester, 10-20 parts of ethylene, 30-50 parts of glass fiber.

[0034] The production process is as follows: first add stone powder, glass fiber, 109 resin, and polystyrene into the mixing equipment, and then add other components and stir until they are evenly mixed. The mixing equipment is an existing mixer, and will not be described here. Preheat the mold to 120-150°C, first pour the mixture into the lower mold to cover the bottom of the lower mold, then put the steel skeleton, then pour the mixture to cover the steel skeleton, and finally cover the upper mold, at 250-300 Hold the pressure for 8-15 minutes under the hydraulic pressure of 1 ton, and demould.

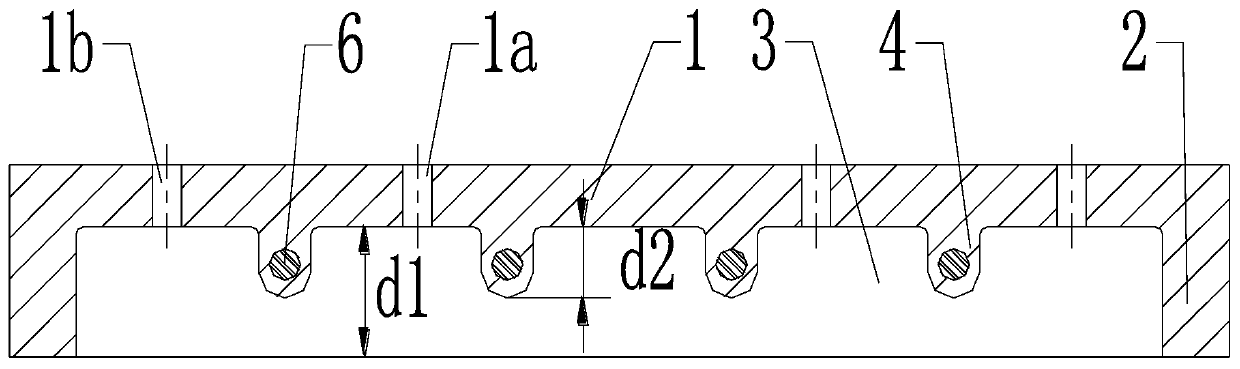

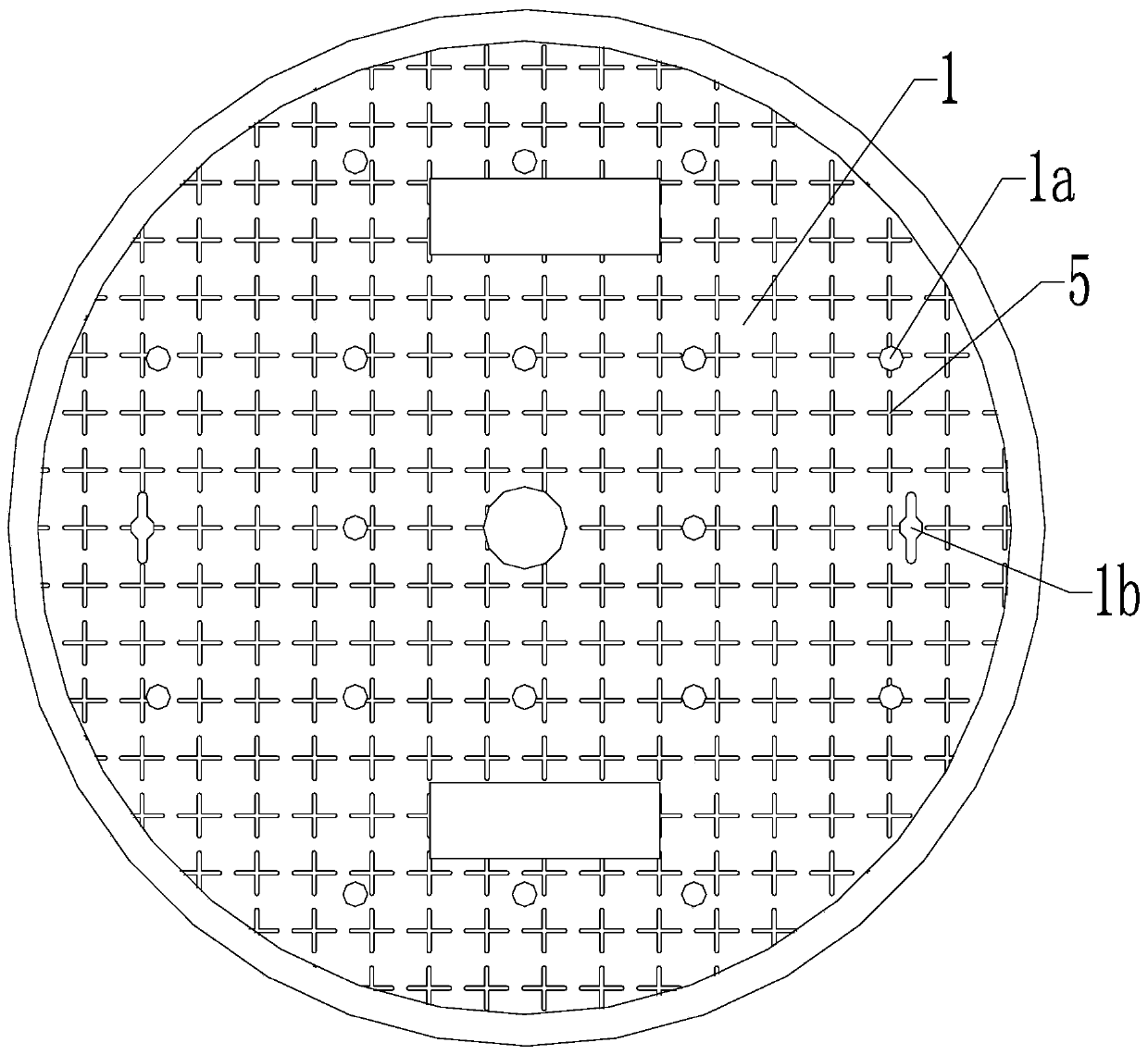

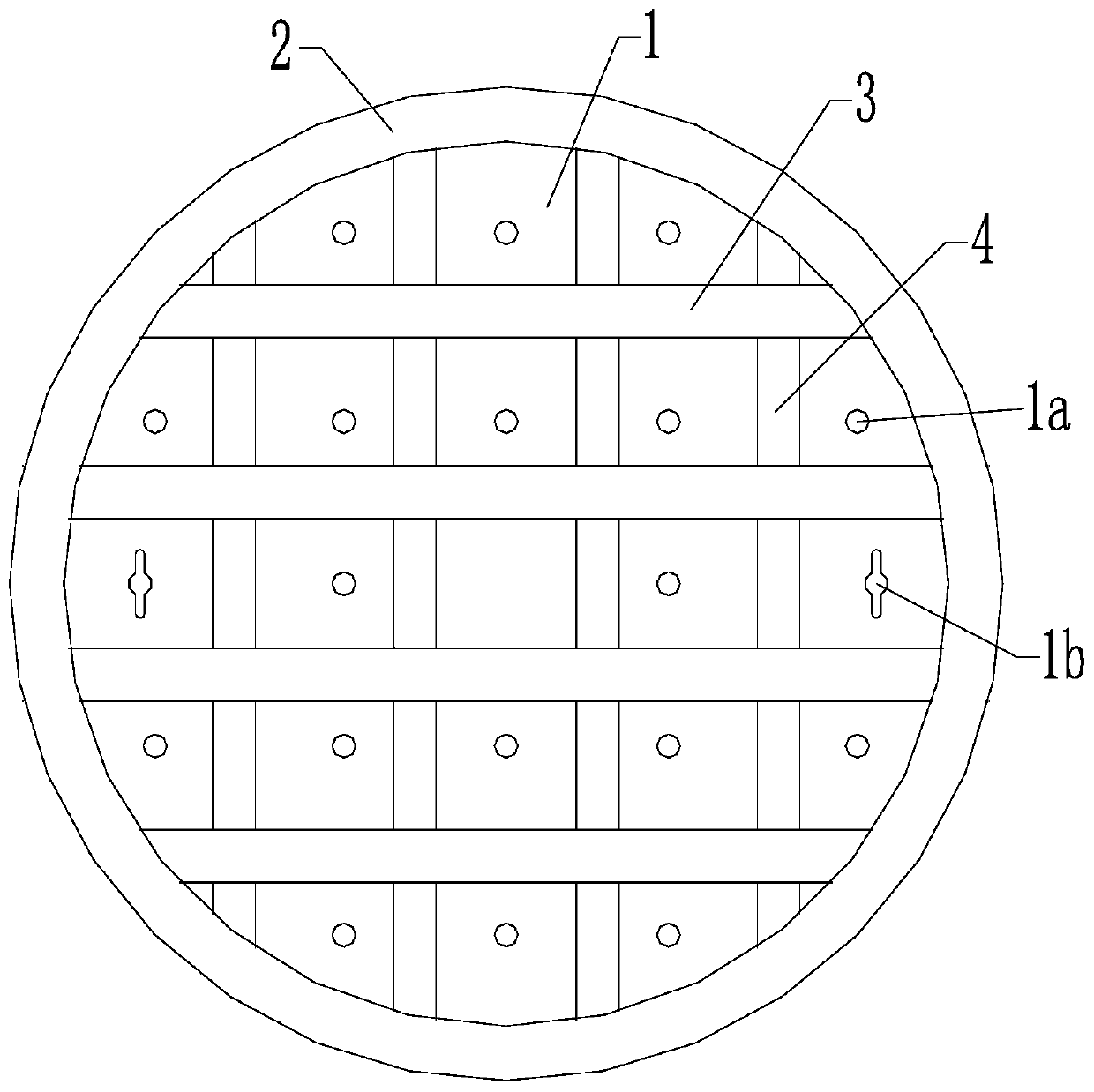

[0035] I...

Embodiment 2

[0041] Such as Figure 6 and Figure 7 As shown, this embodiment provides a sewer manhole cover assembly, including the sewer manhole cover described in Embodiment 1, and also includes a circular well seat 8, the lower end of which is extended inward to form a ring-shaped support portion 8a , the top surface of the support portion 8a is against the bottom surface of the well cover support ring 2, and an anti-falling net 9 is fixed at the lower end of the well base 8, and the anti-falling net 9 is arranged facing the opening of the well base 8. The lower end of the well base 8 extends outward circumferentially to form an annular mounting ring 8b, and the outer wall of the well base 8 protrudes outward to form a plurality of circumferentially uniform reinforcing blocks 8c, and the lower end of the reinforcing block 8c is in contact with the mounting ring. The top surfaces of 8b are integrally connected. In this embodiment, preferably, there are eight reinforcing blocks 8c even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com