Oil-based shale cuttings proppant and preparation method thereof

A technology of proppant and cuttings, applied in the field of oil and gas field development and research, to solve the problem of environmental pollution, realize the effective utilization of waste, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing an oil-based shale cuttings proppant, comprising the following steps:

[0035] 1. Add 5g of phenolic resin to 50ml of ethanol, stir magnetically for 15 minutes to obtain a binder solution, then add 5g of oil-based shale cuttings to it, and stir mechanically for 15 minutes to obtain a cuttings mixed solution.

[0036] 2. Add 25g of industrial ceramsite into the cuttings mixed solution, mechanically stir for 60s, filter, wash with deionized water, and dry at a drying temperature of 40°C-100°C to obtain an oil-based shale cuttings proppant.

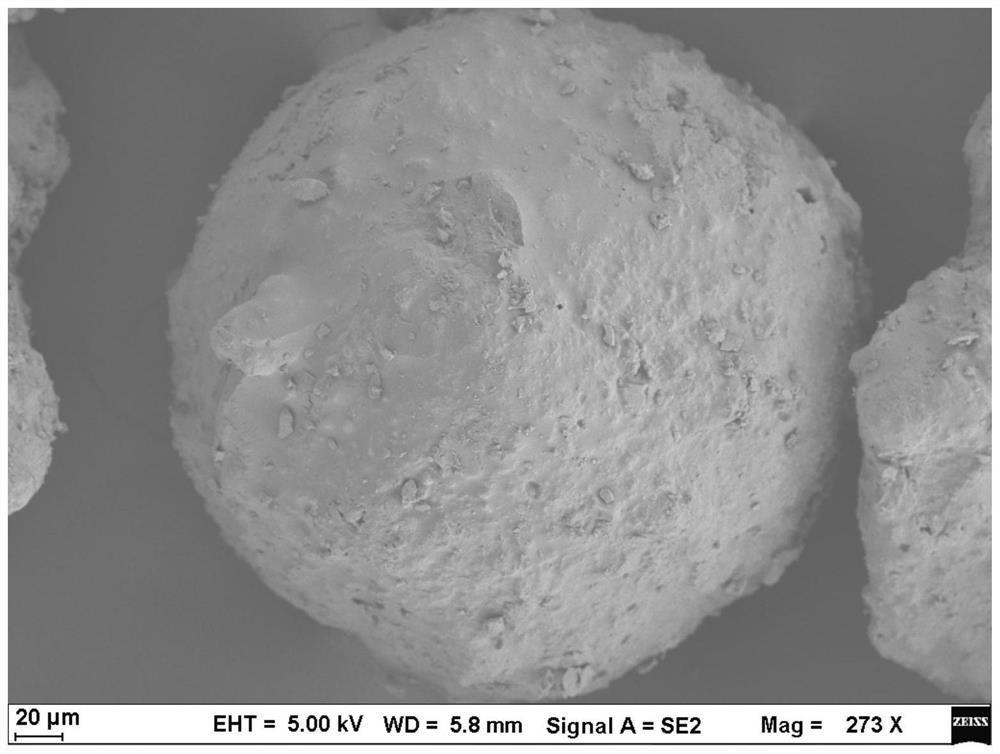

[0037] figure 1 SEM image of the oil-based shale cuttings proppant prepared for this example. From figure 1 It can be seen from the figure that the surface of oil-based shale cuttings is smooth, and the original unevenness on the surface of industrial ceramsite is basically filled by oil-based shale cuttings and binder to become a round sphere.

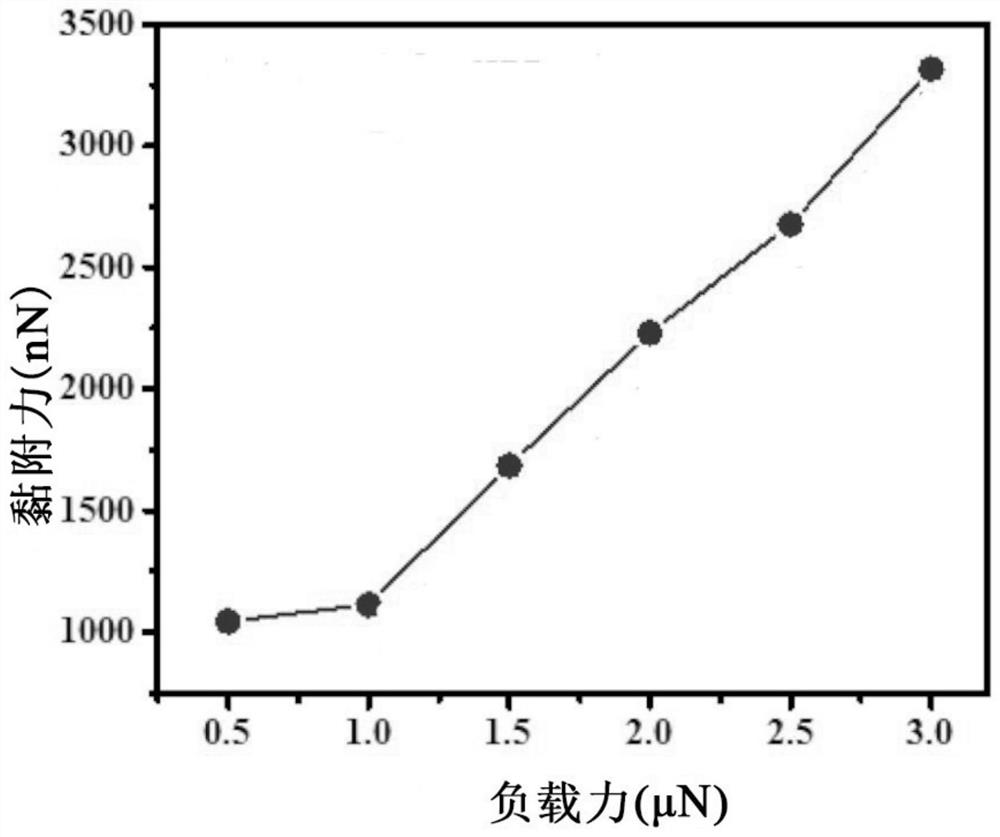

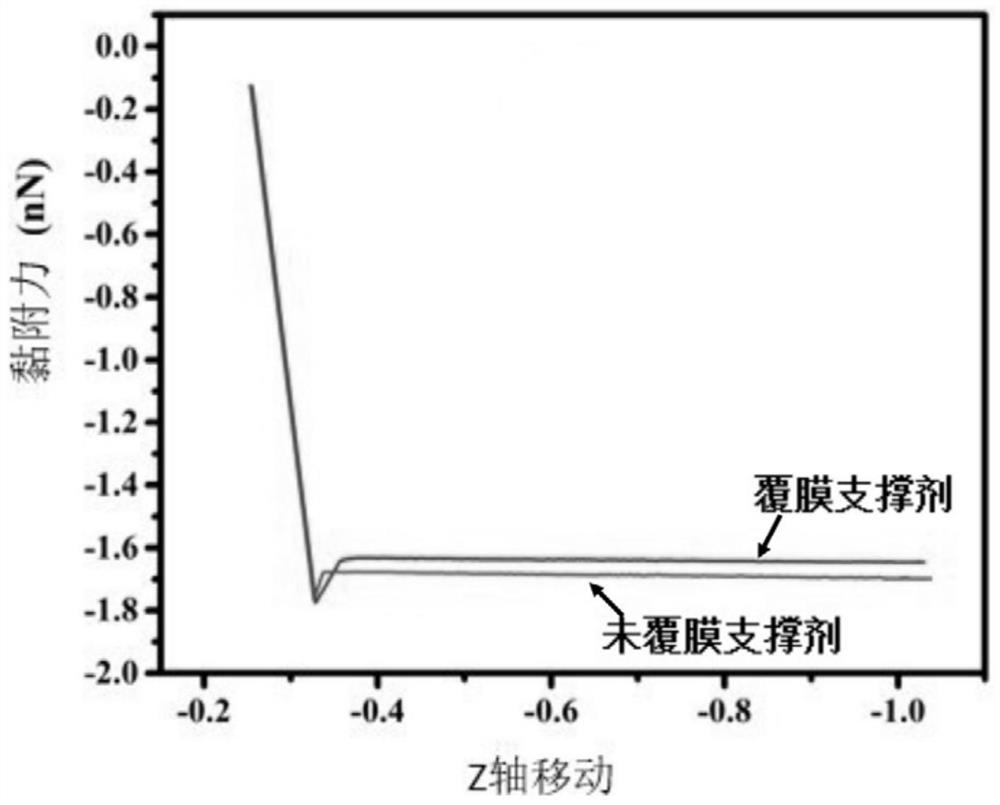

[0038] figure 2 , image 3 It is th...

Embodiment 2

[0041] This embodiment provides a method for preparing an oil-based shale cuttings proppant, comprising the following steps:

[0042] 1. Add 10g of phenolic resin to 50ml of ethanol, stir magnetically for 15 minutes to obtain a binder solution, then add 15g of oil-based shale cuttings to it, and stir mechanically for 15 minutes to obtain a cuttings mixed solution.

[0043] 2. Add 15g of industrial ceramsite into the cuttings mixed solution, mechanically stir for 600s, filter, wash with deionized water, and dry at a drying temperature of 40°C-100°C to obtain an oil-based shale cuttings proppant.

[0044] Figure 5 SEM image of the oil-based shale cuttings proppant prepared for this example. From Figure 5 It can be clearly observed that the surface of the proppant is covered with relatively thick oil-based shale cuttings and binder.

Embodiment 3

[0046]This embodiment provides a method for preparing an oil-based shale cuttings proppant, comprising the following steps:

[0047] 1. Add 10g of phenolic resin to 50ml of ethanol, stir magnetically for 15 minutes to obtain a binder solution, then add 10g of oil-based shale cuttings to it, and stir mechanically for 15 minutes to obtain a cuttings mixed solution.

[0048] 2. Add 25g of industrial ceramsite into the cuttings mixed solution, mechanically stir for 3 hours, filter, wash with deionized water, and dry at a drying temperature of 40°C-100°C to obtain the oil-based shale cuttings proppant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com