Local vacuum casting method for aluminum alloy

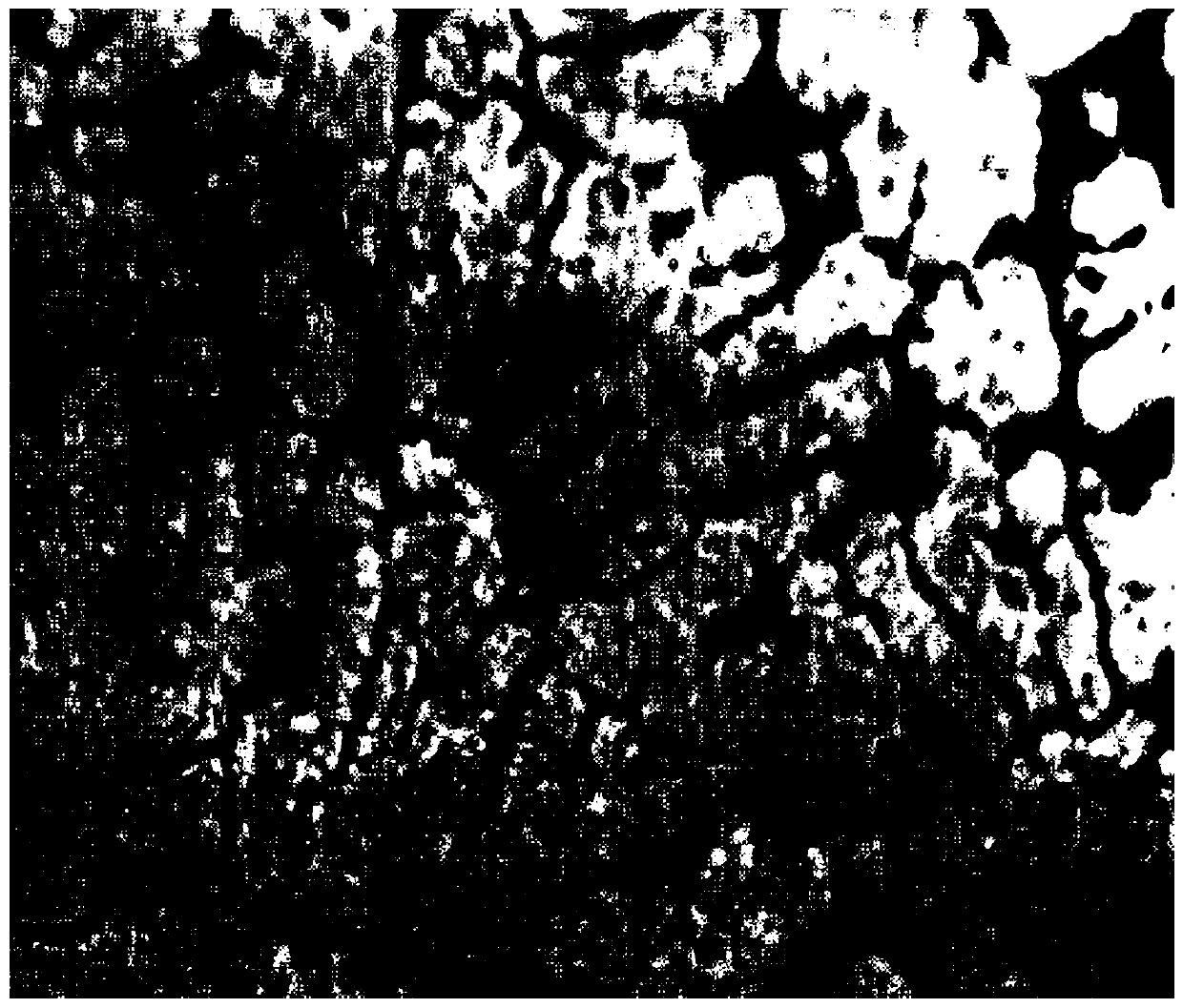

A partial vacuum, aluminum alloy technology, applied in the field of partial vacuum casting of aluminum alloys, can solve the problems of high energy consumption, thick dendrites, and no specific solutions are proposed, and achieve stable dendrite spacing, fewer hole defects, and improved rolling. The effect of the slag phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

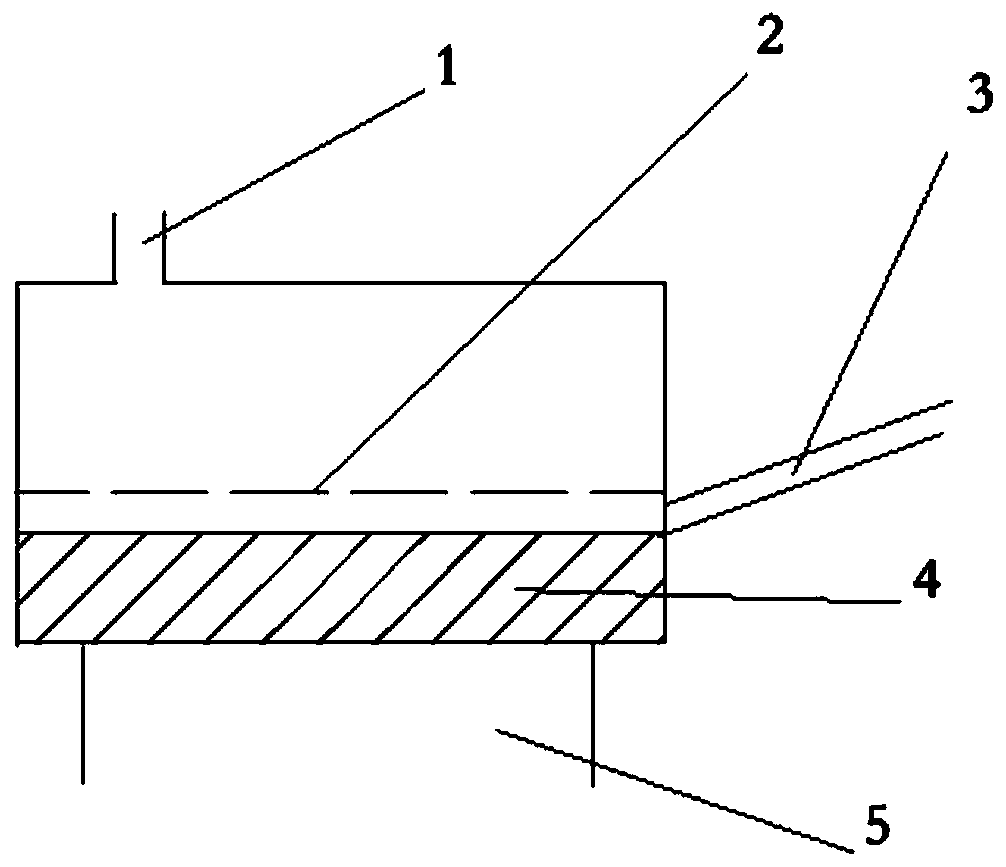

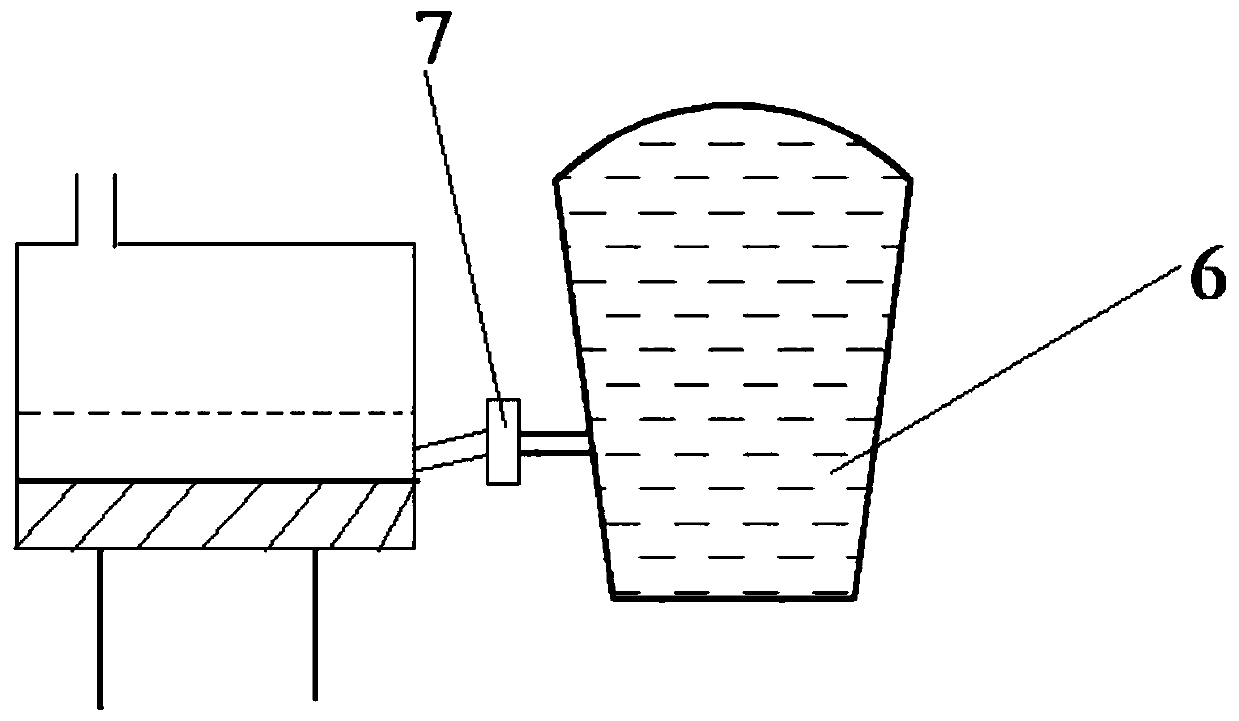

Method used

Image

Examples

Embodiment 1

[0036] A method for aluminum alloy partial vacuum casting, comprising the following steps:

[0037] (1) Based on the total weight of the aluminum alloy, the aluminum alloy elements include 4.2% Mg, 0.03% Mn, 0.02% Cr, 0.35% Fe, 0.07% Ti, 0.25% Cu, and 0.25% trace elements %, the balance is Al and other inevitable impurities, the single content of other inevitable impurities is ≤0.05%, and the total amount is ≤0.15%;

[0038] (2) Add aluminum ingots to the smelting furnace of the vacuum electromagnetic guide device, and heat the aluminum ingots in the smelting furnace to melt into melt one;

[0039] (3) Carry out ultrasonic vibration treatment and mechanical stirring treatment to melt one, continue to add the above-mentioned components Mn, Cr, Fe, Ti in the weight percentage in the melting furnace, control the melt temperature in the melting furnace to be 650-750 ℃ to The alloy is completely melted, and the temperature is maintained at 650°C, and Mg 4.18% is added until the ...

Embodiment 2

[0045] A method for aluminum alloy partial vacuum casting, comprising the following steps:

[0046] (1) Based on the total weight of the aluminum alloy, the aluminum alloy elements include Mg5.5%, Mn0.35%, Cr0.25%, Fe0.65%, Ti0.12%, Cu0.45%, Trace elements 0.35%, the balance is Al and other inevitable impurities, the single content of other inevitable impurities is ≤0.05%, and the total amount is ≤0.15%;

[0047] (2) Add aluminum ingots to the smelting furnace of the vacuum electromagnetic guide device, and heat the aluminum ingots in the smelting furnace to melt into melt one;

[0048] (3) Carry out ultrasonic vibration treatment and mechanical stirring treatment to melt one, continue to add the above-mentioned components Mn, Cr, Fe, Ti in the weight percentage in the melting furnace, control the melt temperature in the melting furnace to be 650-750 ℃ to The alloy is completely melted, and the temperature is kept at 750°C, and Mg 5.42% is added until the melt is uniform to...

Embodiment 3

[0054] A method for aluminum alloy partial vacuum casting, comprising the following steps:

[0055] (1) Based on the total weight of the aluminum alloy, the aluminum alloy elements include 5.0% of Mg, 0.3% of Mn, 0.15% of Cr, 0.45% of Fe, 0.09% of Ti, 0.32% of Cu, and 0.30% of trace elements %, the balance is Al and other inevitable impurities, the single content of other inevitable impurities is ≤0.05%, and the total amount is ≤0.15%;

[0056] (2) Add aluminum ingots to the smelting furnace of the vacuum electromagnetic guide device, and heat the aluminum ingots in the smelting furnace to melt into melt one;

[0057] (3) Carry out ultrasonic vibration treatment and mechanical stirring treatment to the melt, continue to add the above-mentioned components Mn, Cr, Fe, Ti in the weight percentage to the melting furnace, and control the temperature of the melt in the melting furnace to 700 ° C until the alloy is completely Melt, and keep the temperature at 700°C and add Mg4.73% t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com