A kind of process of coating CuO film on the surface of cubic boron nitride

A cubic boron nitride, thin film technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of low CBN abrasive holding force and short service life of grinding wheel, and achieve good wettability, Extended service life, small grain size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

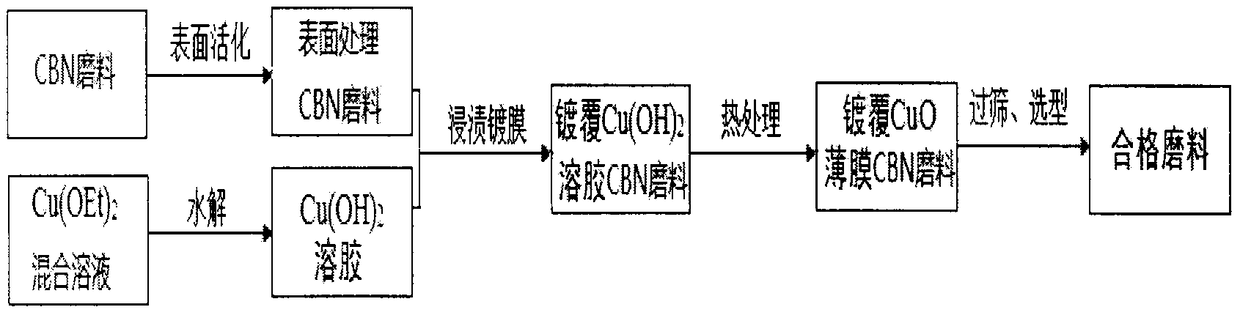

[0020] see figure 1 , in an embodiment of the present invention, a process for coating a CuO film on the surface of cubic boron nitride comprises the following steps:

[0021] (1) Carry out surface treatment to CBN abrasive: first CBN abrasive is immersed in the NaOH solution that temperature is 40 ℃, concentration is 1mol / L, carries out activation treatment to the surface, treatment time is 1.5 hours, then rinses abrasive surface with deionized water, Until the pH of the cleaning solution is 7.0, finally use ultrasonic waves with a frequency of 60KHz to clean the surface of the abrasive in an anhydrous ethanol medium for 0.5 hours, and dry the cleaned CBN abrasive at 60°C for use.

[0022] (2) Preparation of CBN abrasives coated with CuO film on the surface: in chemically pure Cu(OEt) 2 Add analytically pure triethanolamine to the solution, Cu(OEt) 2 The volume ratio with triethanolamine is 100:1, the mixed solution is stirred at a high speed at 6000 rpm for 1 hour, and the...

Embodiment 2

[0024] see figure 1 , in an embodiment of the present invention, a process for coating a CuO film on the surface of cubic boron nitride comprises the following steps:

[0025] (1) Surface treatment of CBN abrasives: First, CBN abrasives are immersed in a NaOH solution with a temperature of 50°C and a concentration of 1mol / L, and the surface is activated for 1 hour, and then the surface of the abrasives is rinsed with deionized water. Until the pH of the cleaning solution is 7.5, finally use ultrasonic waves with a frequency of 40KHz to clean the surface of the abrasive in an anhydrous ethanol medium for 1.5 hours, and dry the cleaned CBN abrasive at 60°C for use.

[0026] (2) Preparation of CBN abrasives coated with CuO film on the surface: in chemically pure Cu(OEt) 2 Add analytically pure triethanolamine to the solution, Cu(OEt) 2 The volume ratio with triethanolamine was 100:1, and the mixed solution was stirred at 2000 rpm for 1.5 hours, and then to Cu(OEt) under high-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com