New energy automobile power battery powder dryer

A technology for new energy vehicles and power batteries, which is applied in the directions of drying solid materials, drying gas layout, non-progressive dryers, etc. Easy to use and improve the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

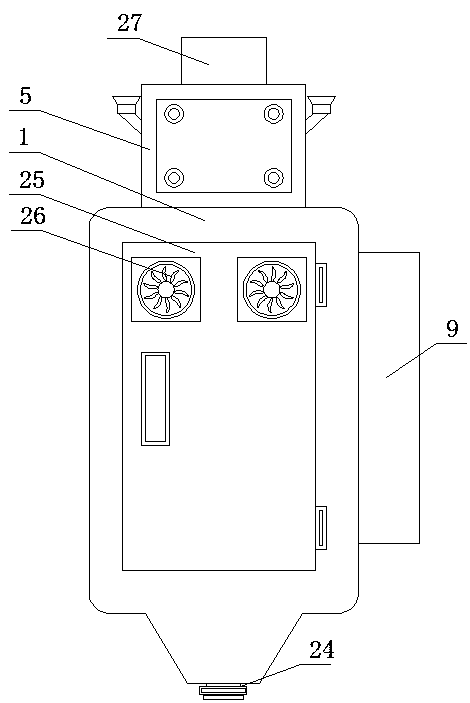

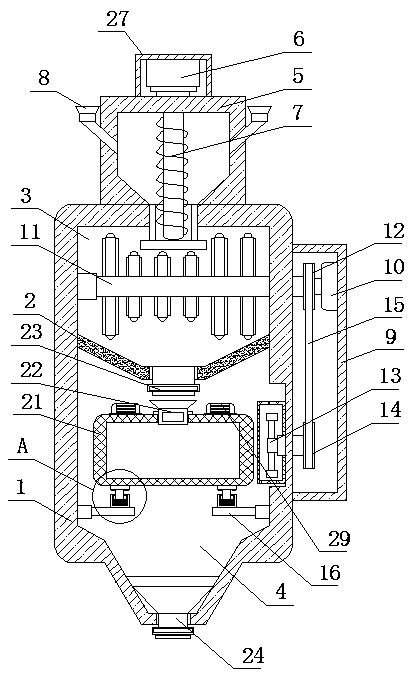

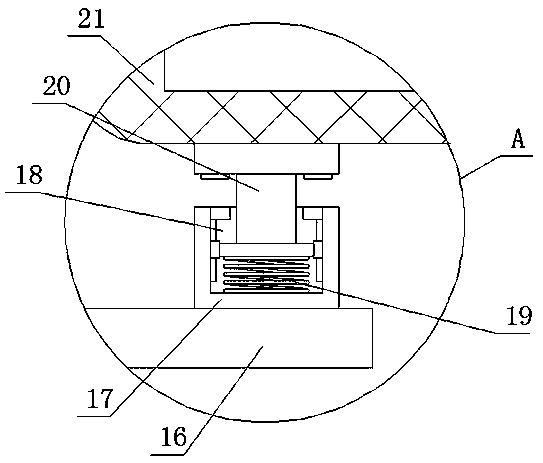

[0026] refer to Figure 1-5 , a new energy vehicle power battery powder dryer, including a housing 1, a suitable partition 2 is fixedly installed in the housing 1, and the partition 2 divides the housing 1 into a drying chamber 3 and a screening chamber 4. A delivery box 5 is fixedly installed on the top of the housing 1. A feeding assembly is arranged inside the delivery box 5. A through hole communicating with the housing 1 is opened at the bottom of the delivery box 5. The inner wall of one side of the drying chamber 3 rotates A rotating shaft 11 is provided, an opening is opened on one side of the housing 1, and a box door 25 is hinged on the opening for sealing and rotating, and a hot air blower 26 is arranged on the box door 25, and the air outlet of the hot air blower 26 extends into the drying chamber 3 , the bottom inner wall of the drying chamber 3 is provided with a feeding pipe 23, the feeding pipe 23 is provided with a first electric valve, the inner walls of both...

Embodiment 2

[0028]The feeding assembly includes a protective box 27 fixedly installed on the top of the delivery box 5. A driving motor 6 is fixedly installed in the protective box 27. The output shaft of the driving motor 6 extends into the delivery box 5 and is fixedly installed with a screw propulsion shaft 7. The screw propulsion shaft The bottom of 7 extends into the through hole, and both sides of the delivery box 5 are fixedly connected with the feed pipe 8 connected to each other. By using the feed pipe 8, the battery powder can be put into the delivery box 5. When in the drying chamber 3, start the driving motor 6 at this time to drive the screw propulsion shaft 7 to rotate, and the screw propulsion shaft 7 can put the powder into the drying chamber 3, and the screw propulsion shaft 7 can be used to feed the powder to the drying chamber in a regular and quantitative manner. In the dry chamber 3; the power assembly includes a mounting box 9 fixedly installed on one side of the hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com