Processing device for meat ball food

A kind of processing equipment and meatball technology, which is applied in the direction of meat processing, application, meat extrusion, etc., can solve the problems of loose meatballs, small forming force, poor forming effect, etc., and achieve convenient and fast forming, good extrusion effect, and convenient raw material processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

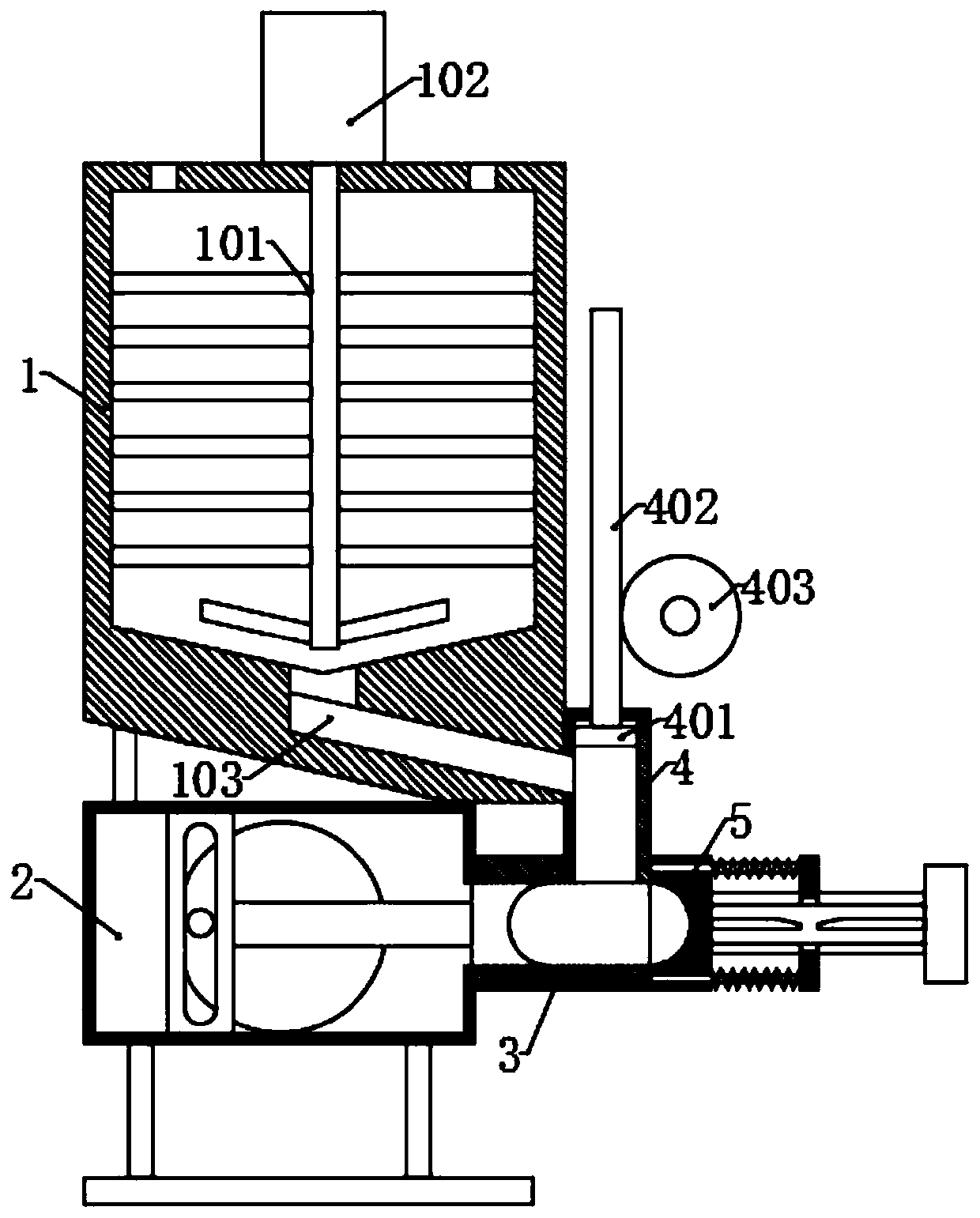

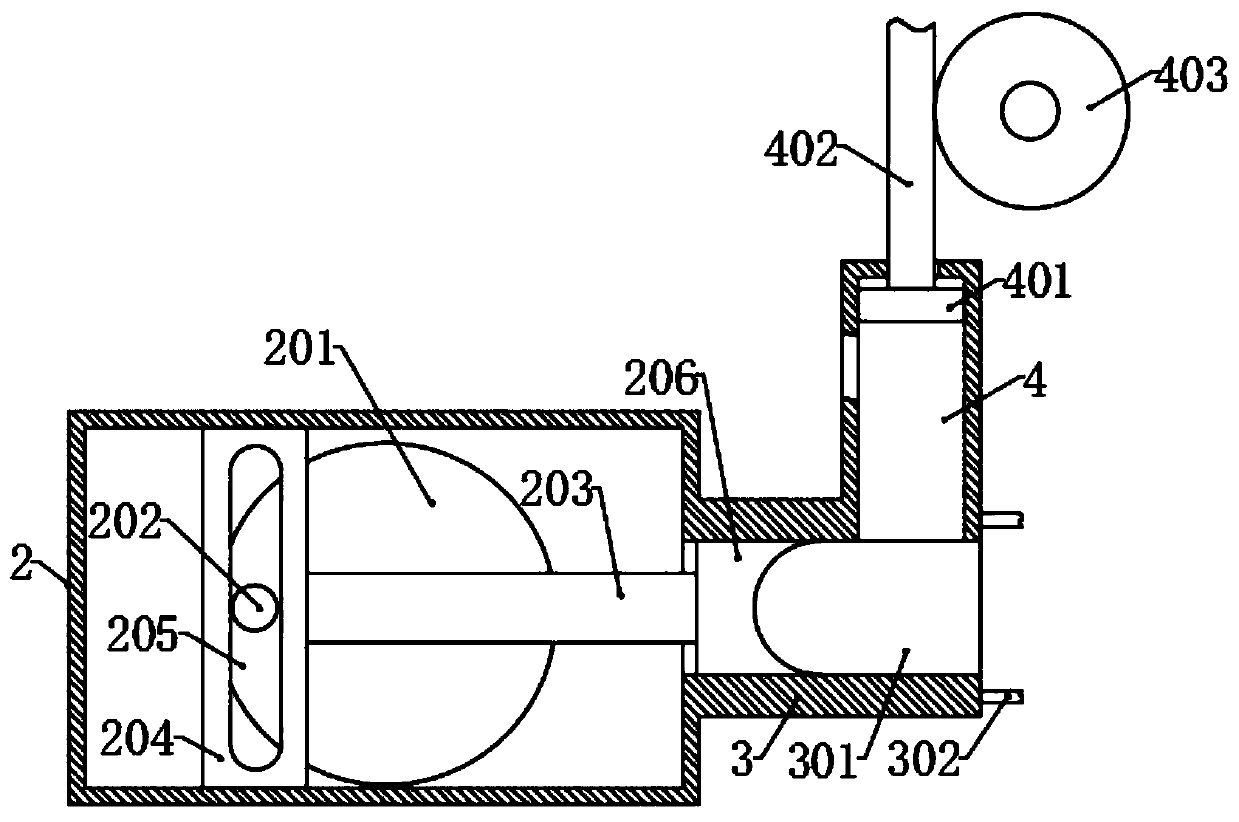

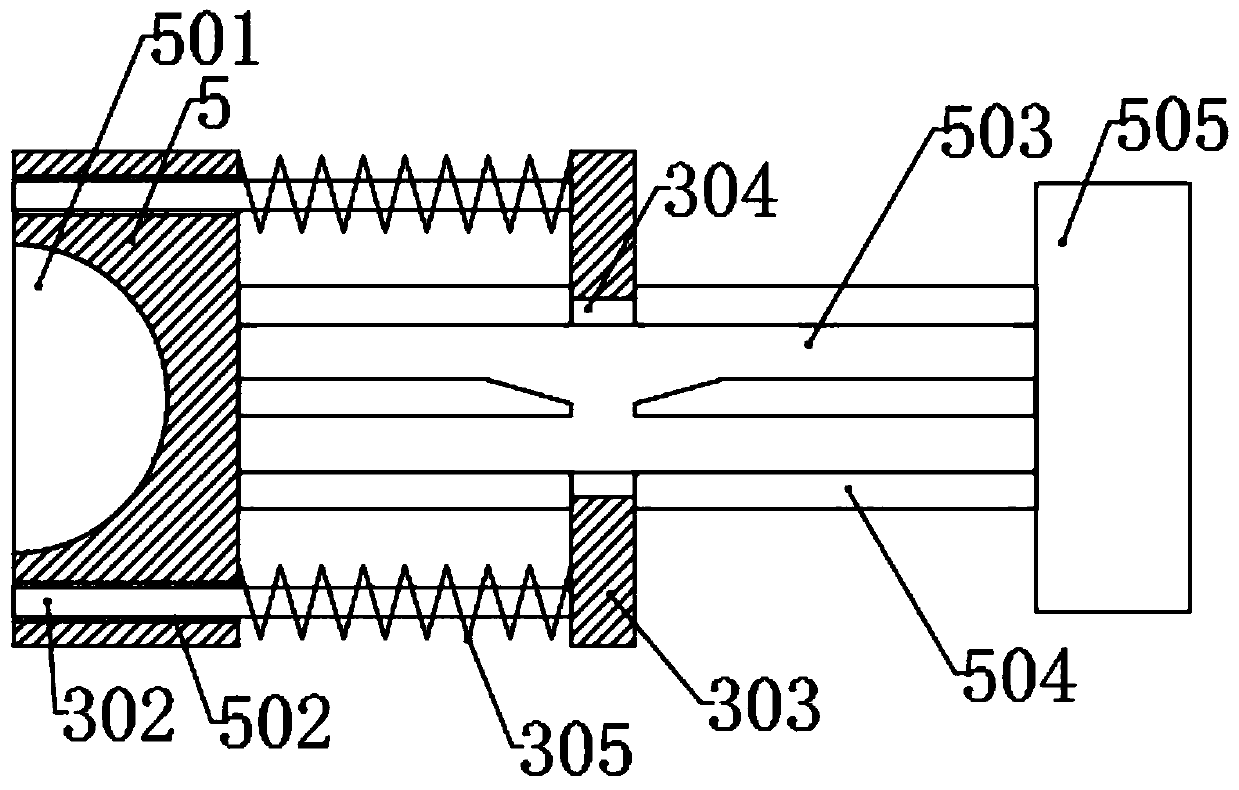

[0034] Please refer to the accompanying drawings, the present invention provides a technical solution: a processing equipment for meatball food, comprising a mixing box 1, a driving box 2, an extruding plate 3, a fixing plate 4 and a forming template 5, the mixing A stirring shaft 101 is rotatably connected to the box 1, and the top of the stirring shaft 101 passes through the top surface of the mixing box 1 and is connected with a stirring motor 102. The bottom surface of the mixing box 1 is provided with a discharge port, and a Inclined material guide cavity 103, the bottom side of the material guide cavity 103 is evenly provided with a plurality of communication holes, the fixed plate 4 is fixed on the lower part of one side of the mixing box 1, and the fixed plate 4 is evenly arranged with multiple holes along the length direction. A vertical moving chamber, a moving assembly is arranged in the moving chamber, the extruding plate 3 is vertically fixed on the bottom of the f...

Embodiment 2

[0041] On the basis of Embodiment 1, the top of the mixing box 1 is also provided with a pulverizing box 7, the pulverizing box 7 is provided with a pulverizing shaft, the top of the pulverizing shaft is connected with a pulverizing motor, and the bottom of the pulverizing box 7 is provided with There is a first outlet, and communicates with the top of the mixing box 1 through the first outlet.

[0042] During processing, the unground pork can be directly put into the crushing box 7, and the pork is crushed into the mixing box 1 through the crushing motor and the crushing shaft, and after being fully mixed with other raw materials, the subsequent processing process is carried out without additional The equipment pulverizes the pork and transfers it to the mixing box 1, reducing the processing equipment, simplifying the operation and improving the processing efficiency.

Embodiment 3

[0044] On the basis of Embodiment 2, the top of the mixing box 1 is also provided with a pelletizing box 6, the upper part of the pelletizing box 6 is provided with a feed hopper 601, and the lower part is provided with a pelletizing chamber 602, and the pelletizing box 6 is provided with a pelletizing chamber 602. The top of the chamber 602 communicates with the feed hopper 601, and the upper part is rotatably connected with two cross-cutting shafts 603, and the cross-cutting shafts 603 are uniformly provided with cross-cutting knives 604, and the right ends of the two cross-cutting shafts 603 stretch out from the pelletizing box 6 and The cross-cutting gears are respectively fixed, and the two cross-cutting gears mesh with each other, and one of the cross-cutting gears is connected with a cross-cutting motor, and the lower part of the cutting chamber 602 is rotatably connected with two vertical cutting shafts 605, and the vertical cutting shafts 605 Perpendicular to the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com