Frozen chicken production process and air purification equipment for production thereof

A production process, chicken technology, applied in application, processed meat, poultry processing, etc., can solve problems such as poor quality of frozen meat, achieve the effect of improving cleanliness, inhibiting reproduction, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

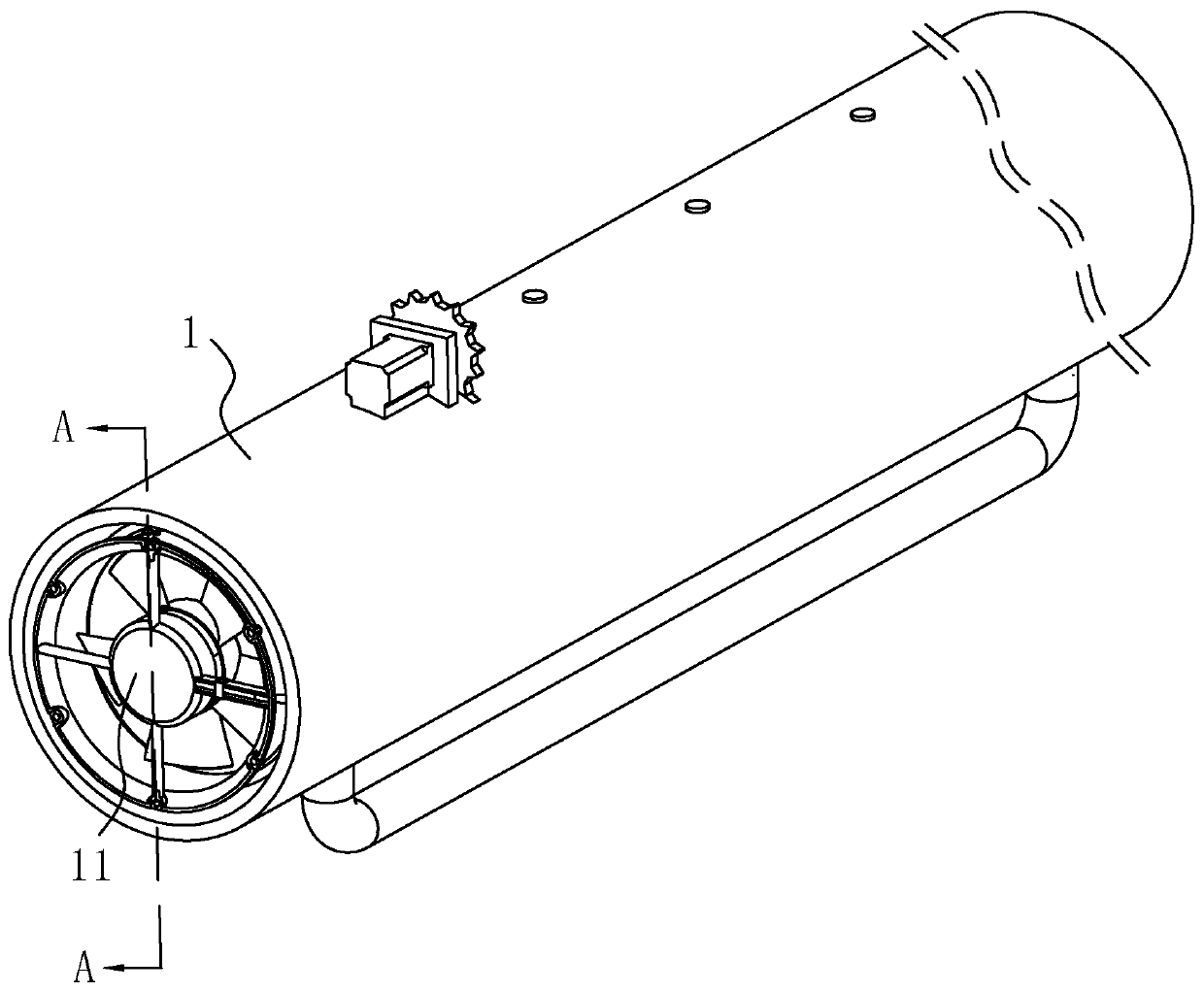

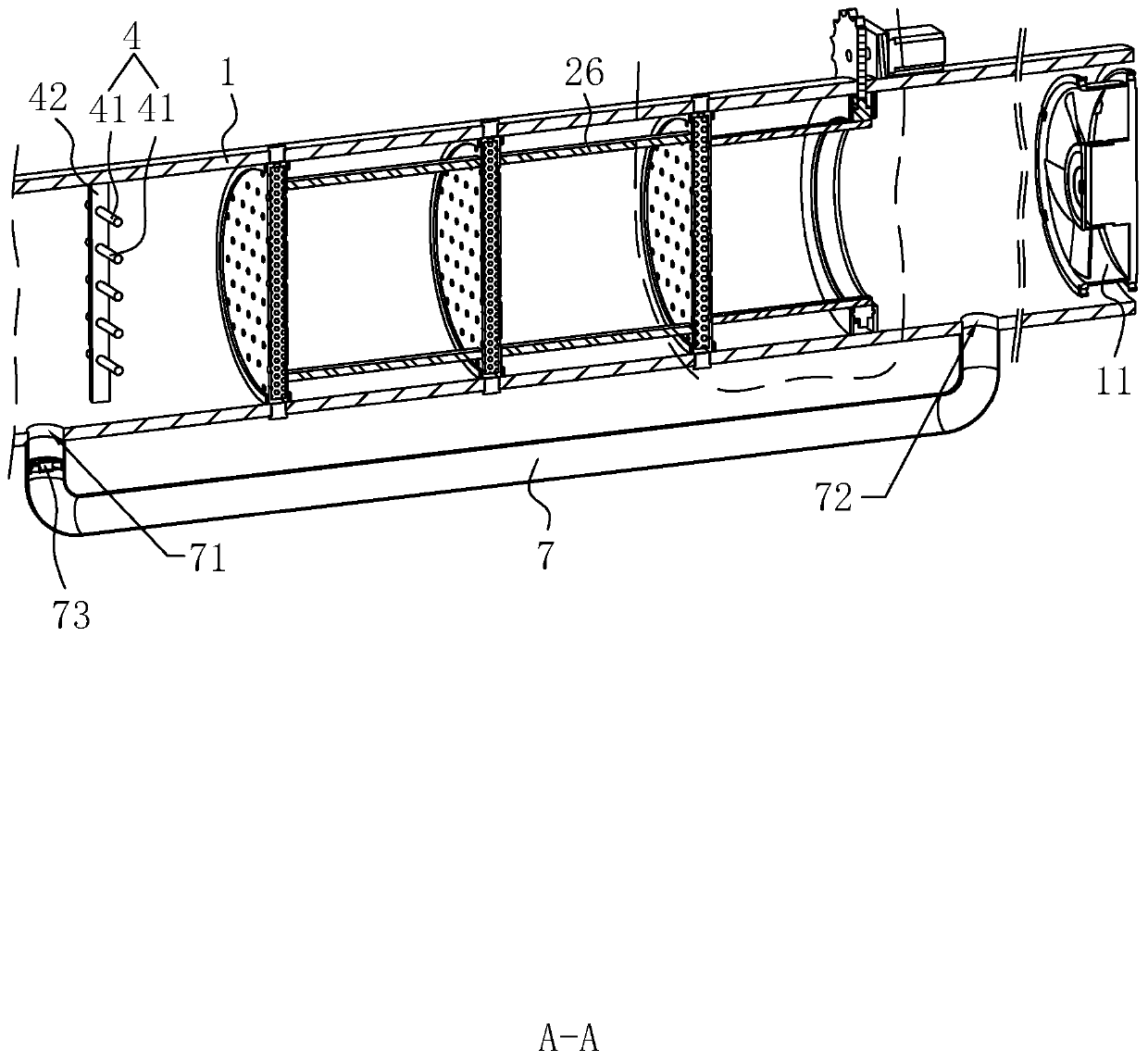

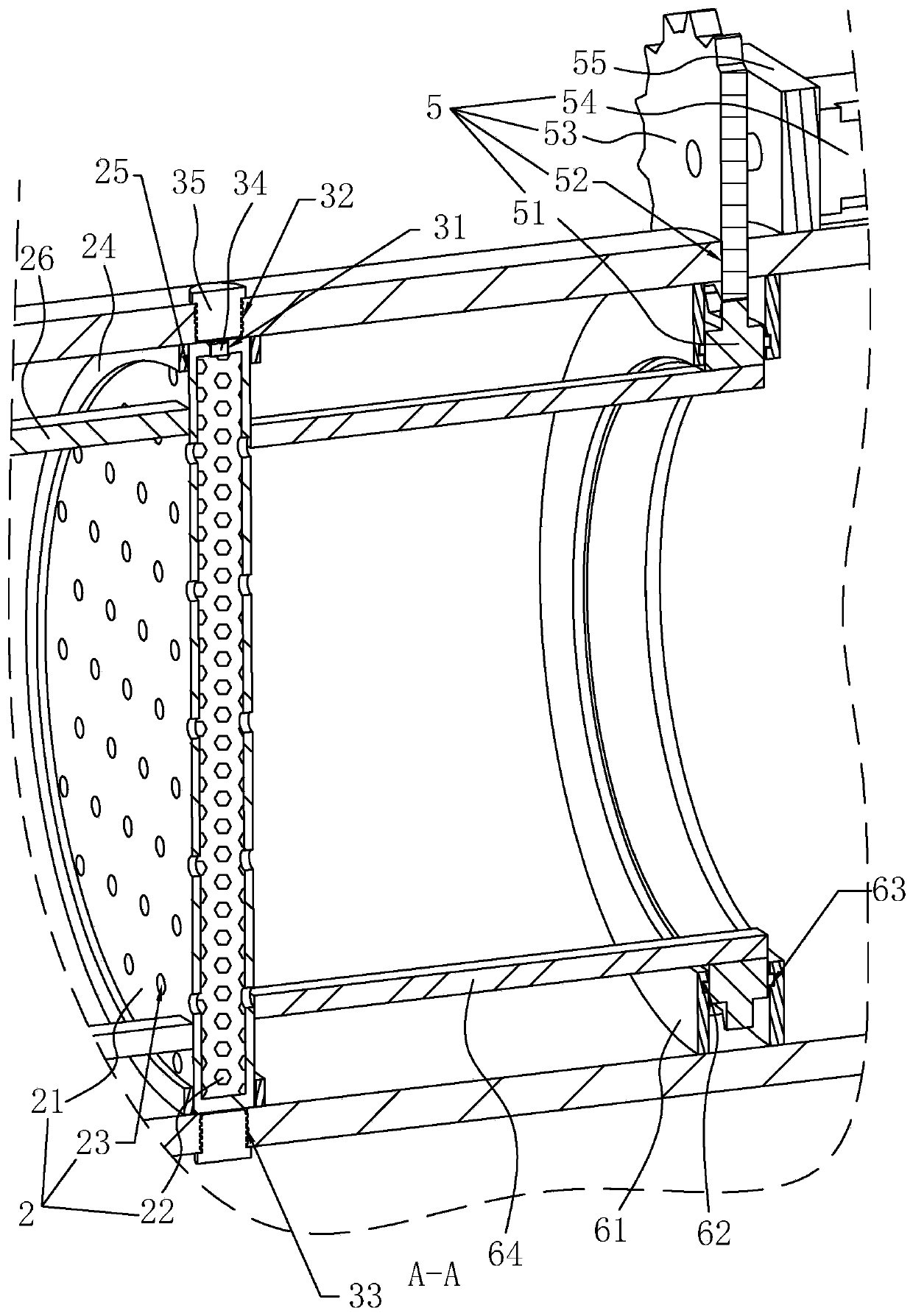

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0054] A frozen chicken production process has the following steps:

[0055] slaughter:

[0056] S11: Hanging the chicken: hang the live chicken upside down and let it stand still; first grab the drumstick of the chicken, hang the chicken upside down on the hook, and then let it stand in the dark room for a period of time;

[0057] S12: Bleeding: Cut off the left artery and vein of the live chicken neck without injuring the trachea and esophagus of the live chicken; after the chicken calms down, cut off the left artery and vein of the live chicken neck with a knife, and the chicken blood flows along the chicken neck outflow;

[0058] S13: Drain blood: Drain blood in a dark room for 230s-310s; after cutting off the veins and arteries of the chicken, let the chicken stand in the dark room for 280s, and treat the chicken blood as waste after the chicken blood ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com