An automatic sealing feeding and discharging device for a coating machine

An automatic sealing, feeding and discharging technology, which is applied in the direction of making medicines into special physical or ingestible devices, coatings, confectionery industry, etc., can solve the problems of affecting production efficiency, high work intensity, low efficiency, etc., to achieve It is convenient for feeding operation, realizes the effect of airtight discharge and reduces environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features, and advantages of the present invention, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

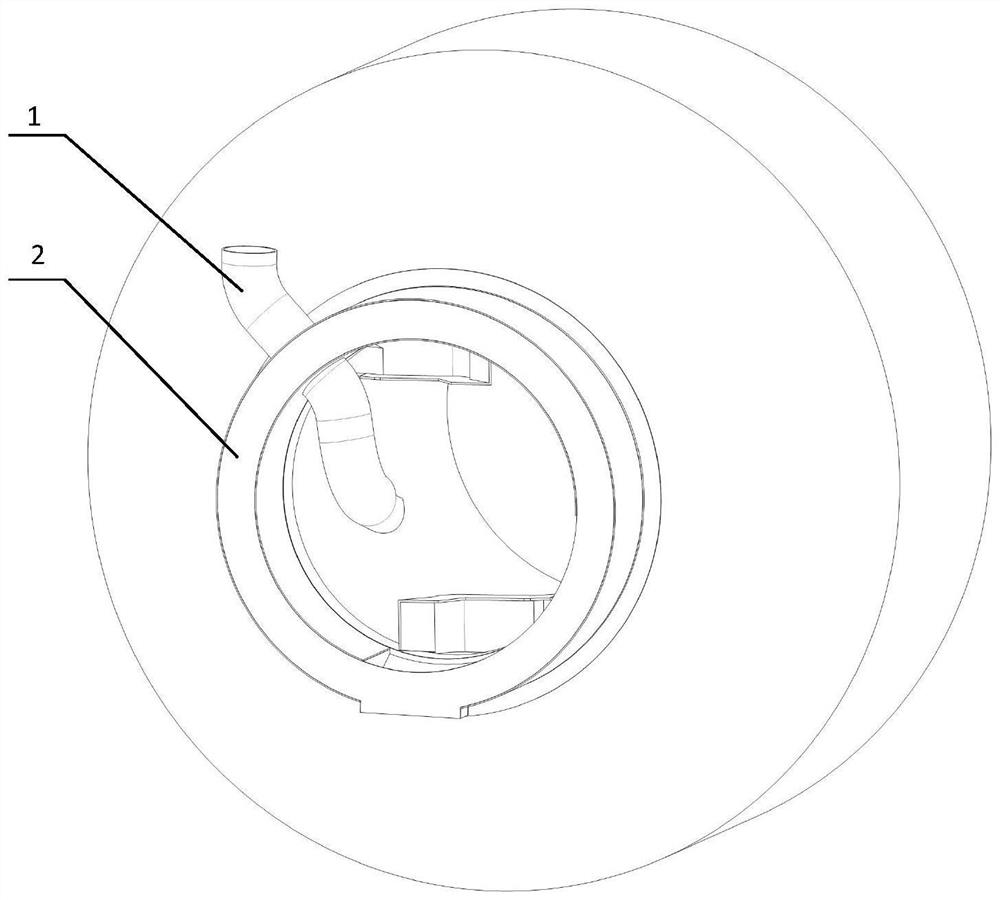

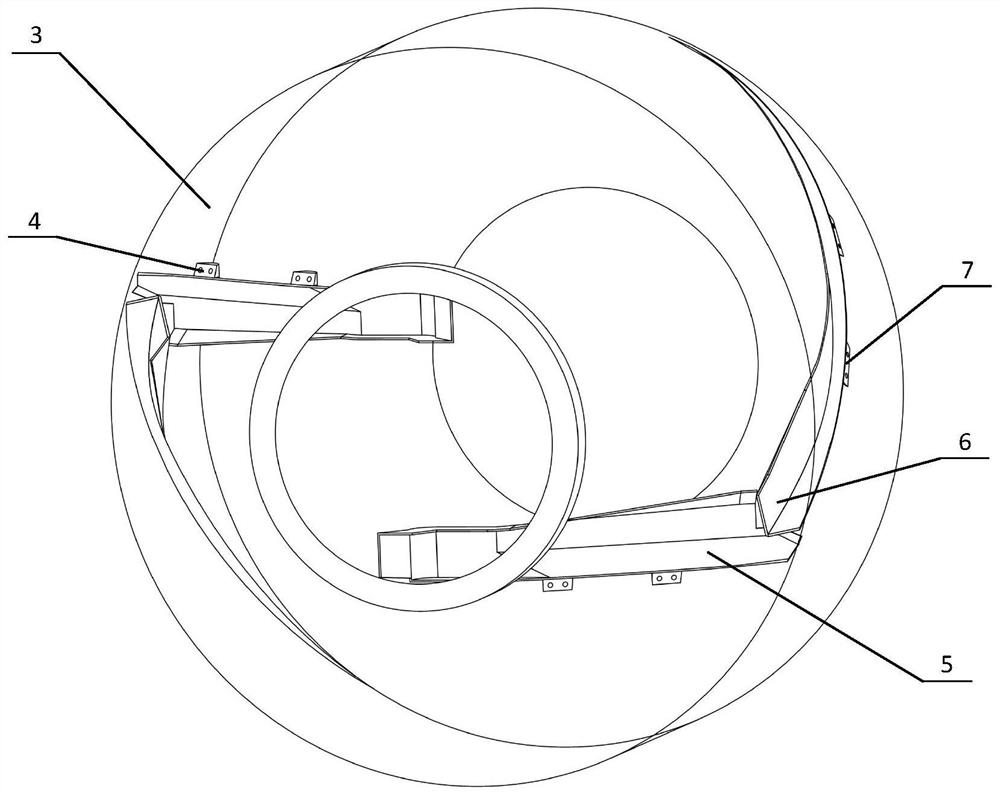

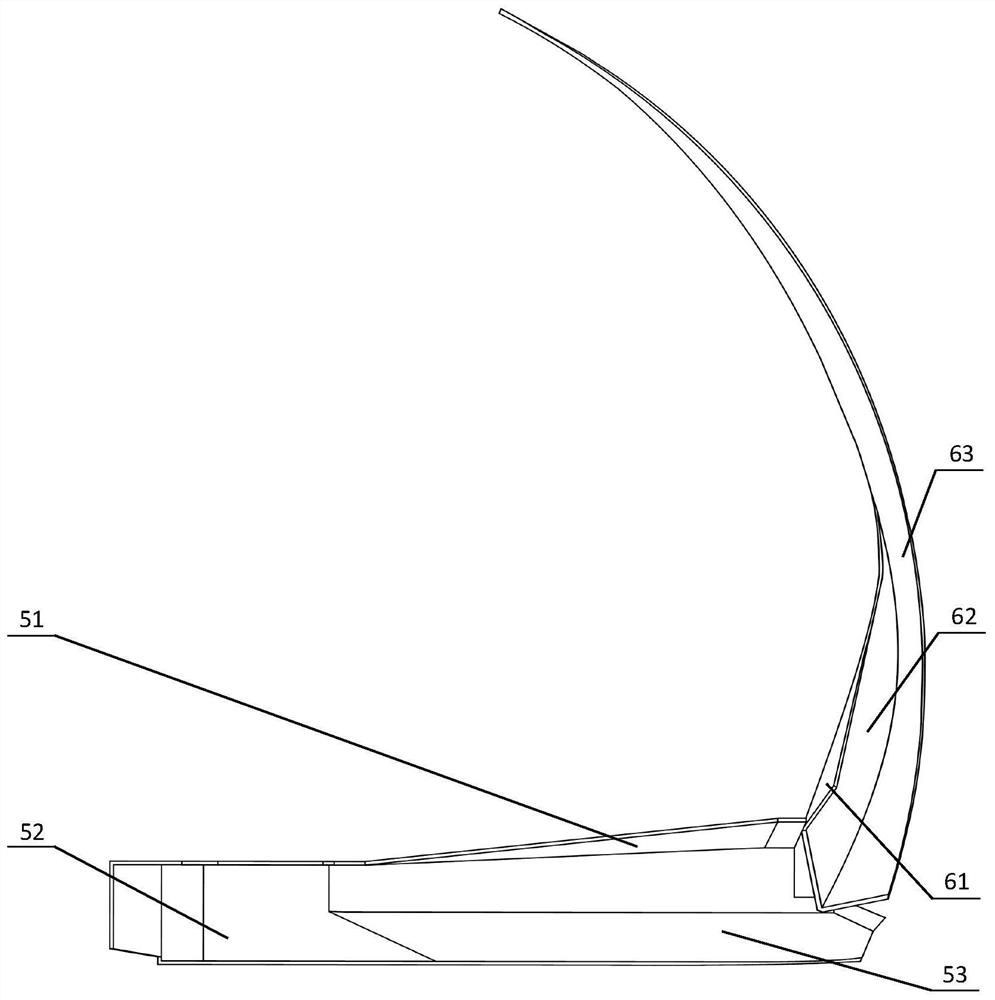

[0026] See Figure 1-4 The coating machine is automatically sealed with the overall structure of the entry and exit device, including the coating cylinder, the large door extension section, the projected blade and the rear projection blade. The front end of the coating cylinder is in the center of which is fully enclosed, the front and rear portion is a tapered bucket, the middle is a cylindrical bucket, the front conical bucket inside the tapered bucket through the screw installation Isolated blade mount, the interior of the central cylindrical bucket is installed after the screw is mounted, and the mount is mounted in the interior of the coating cylinder; the front feed blade welded to the front feed blade mounting seat; The rear proof blade is welded to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com