Material for absorbing and decomposing formaldehyde, and preparation method thereof

A formaldehyde and formaldehyde decomposition technology, applied in the field of air purification, can solve problems such as desorption, and achieve the effects of short reaction time, strong effect, and recyclable photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

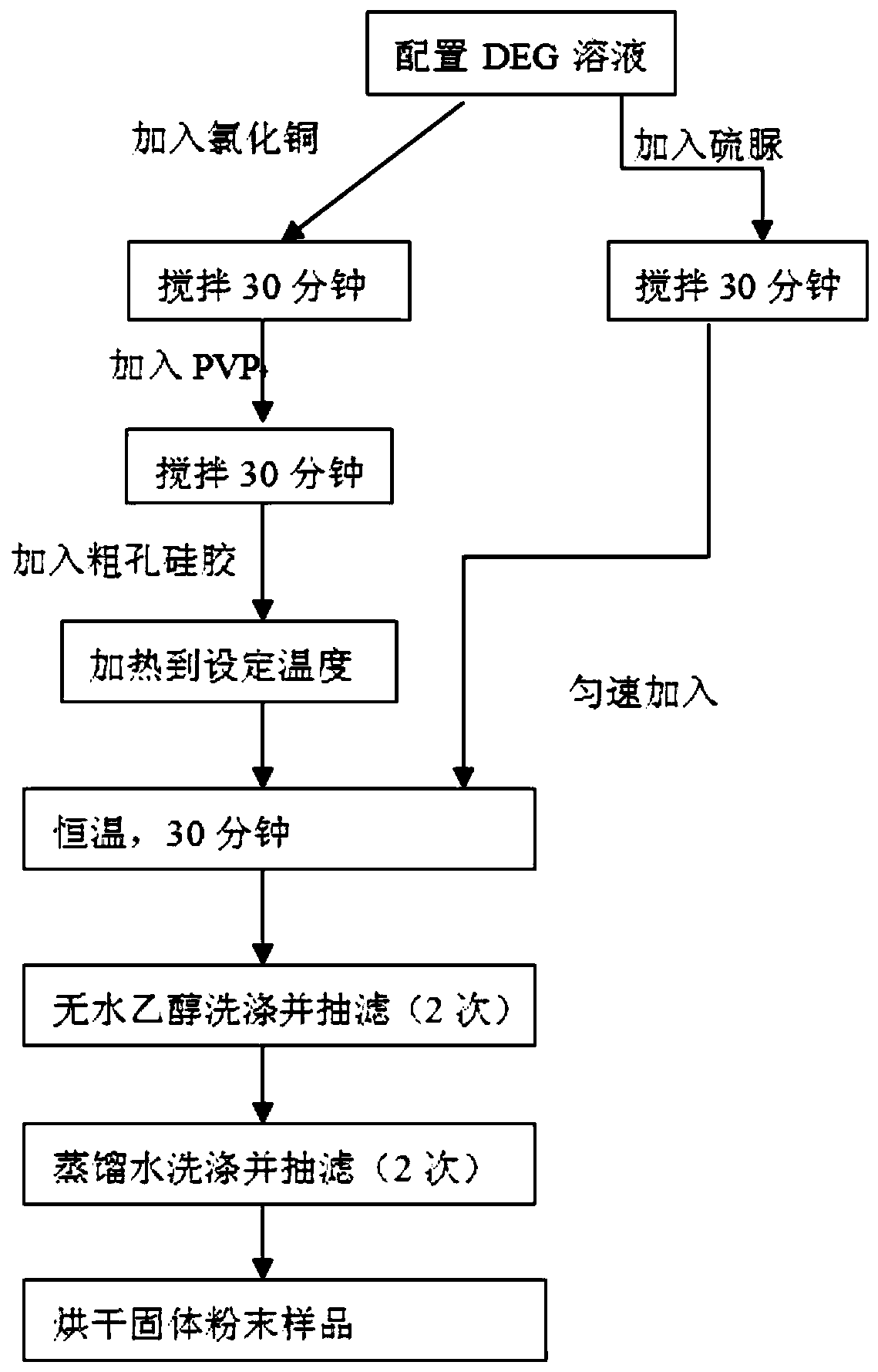

[0051] Such as figure 1 As shown, a material that absorbs and decomposes formaldehyde uses coarse-porous microsphere silica gel as a carrier, and the coarse-porous microsphere silica gel is loaded with p-type semiconductor Cu 2 S; the p-type semiconductor Cu 2 The loading of S was 6%.

[0052] The preparation method of the above-mentioned recycled indoor air purification material is as follows:

[0053] Include the following steps:

[0054] 1), respectively configure the diethylene glycol solution A and the diethylene glycol solution B with a concentration of 0.5mol / L;

[0055] 2), 6.8g CuCl 2 2H 2 O was added to 100ml of diethylene glycol solution A, stirred to make CuCl 2 2H 2 O is completely dissolved, and the stirring adopts a collector type constant temperature heating magnetic stirrer;

[0056] 3), add 2g of polyvinylpyrrolidone to the solution obtained in step 2), and stir until completely dissolved;

[0057] 4) Add 5g of coarse-porous microsphere silica gel to t...

Embodiment 2

[0062] A material that absorbs and decomposes formaldehyde, using coarse-porous microsphere silica gel as a carrier, and the coarse-porous microsphere silica gel is loaded with p-type semiconductor Cu 2 S; the p-type semiconductor Cu 2 The loading of S was 1.6%.

[0063] The difference with the preparation method in Example 1 is:

[0064] CuCl 2 2H 2 The addition of O is 6.8g, the volumes of diethylene glycol solution A and diethylene glycol solution B are 100ml respectively, the addition of polyvinylpyrrolidone is 2.0g, the addition of coarse porous microsphere silica gel 5.0g, coarse porous microsphere silica gel, CuCl in the suspension 2 2H 2 The mass ratio of O and thiourea is 5:6.8:0.38; the oil bath temperature is 190°C.

Embodiment 3

[0066] A material that absorbs and decomposes formaldehyde, using coarse-porous microsphere silica gel as a carrier, and the coarse-porous microsphere silica gel is loaded with p-type semiconductor Cu 2 S; the p-type semiconductor Cu 2 The loading of S is 20%.

[0067] The difference with the preparation method in Example 1 is:

[0068] CuCl 2 2H 2 The add-on of O is 6.8g, and the volume of diethylene glycol solution A and diethylene glycol solution B is respectively 100ml, and the add-on of polyvinylpyrrolidone is 100m, and the add-on of macroporous microsphere silica gel is 5.0g, thiourea add-on is 4.56g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com