Spray paint color mixing system used during manufacturing process of surface of automobile and color mixing method thereof

A technology of intelligent manufacturing and color matching system, which is applied to the spray paint color matching system and its color matching field, can solve the problem of fewer types of color matching, and achieve the effects of increasing the color types of spray paint, good economic benefits, and short deployment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

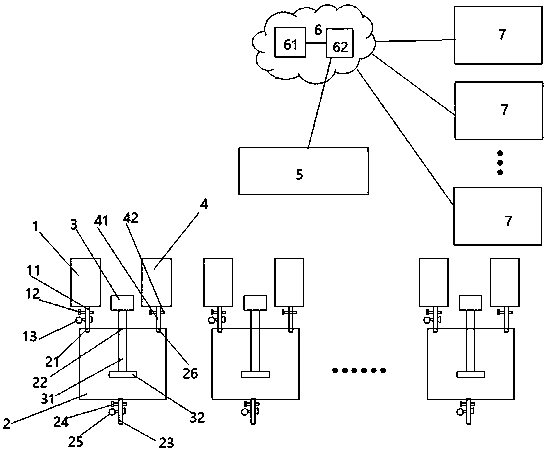

[0019] refer to figure 1 According to the present invention, a paint spraying and toning system in the intelligent manufacturing process of automobile surfaces, the paint spraying and toning system includes: several paint spraying cans 1, each of which is equipped with an environmentally friendly anti-corrosion colorless spray paint, each The discharge end of each described paint spray tank 1 is connected with a discharge pipe 11, and described discharge pipe 11 is provided with discharge valve 12 and discharge pump 13; Paint spray tank 1, the paint spray inlet 21 of the color palette tank 2 communicates with the paint spray tank 1 through the discharge pipe 11, a stirring hole 22 is provided in the middle of the upper surface of the color palette tank 2, and the stirring motor 3 is erected on the color palette tank 2 On the surface, the output end of the stirring motor 3 is connected with a stirring shaft 31, and the stirring shaft 31 is stretched into the inside of the color...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap