A method of removing impurities suitable for tobacco leaf fragments

A technology for tobacco leaf fragments and fragments, applied in chemical instruments and methods, tobacco, applications, etc., can solve problems such as inability to remove debris, and achieve the effects of cleaning impurities, improving purity, and reducing labor and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

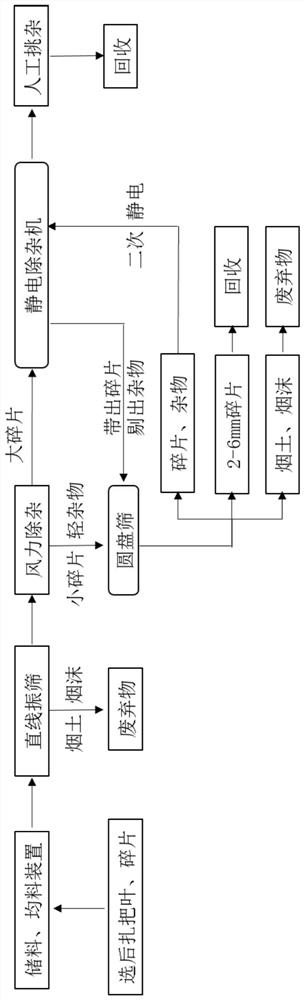

[0025] like figure 1 Shown, the present invention is applicable to the impurity removal method of tobacco leaf fragment, and it comprises the steps:

[0026] (1) Use the feeding bin to output the tobacco leaf fragments that need to be processed, wherein the moisture content of the imported tobacco leaf fragments is not higher than 20%;

[0027] (2) Homogenizing and thinning the tobacco leaves output from the feeding bin through the homogenizing roller;

[0028] (3) Use a linear vibrating sieve to process the homogenized and thinned tobacco leaf fragments, separate the mixed tobacco soil and tobacco powder and treat them as waste;

[0029] (4) Use wind power removal equipment to air-select the tobacco leaf fragments after linear vibrating screening, and at the same time, divide the small fragments and light impurities separated by air separation into one output, and the remaining large pieces of tobacco leaf fragments and heavy The debris is divided into one output;

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com