A high-efficiency dust removal equipment for solar photovoltaic panels

A technology for solar photovoltaic panels and dust removal equipment, applied in photovoltaic modules, photovoltaic power generation, cleaning methods and appliances, etc., can solve the problems of easy freezing, lack of promotion, large water demand, etc., and achieve the effect of good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

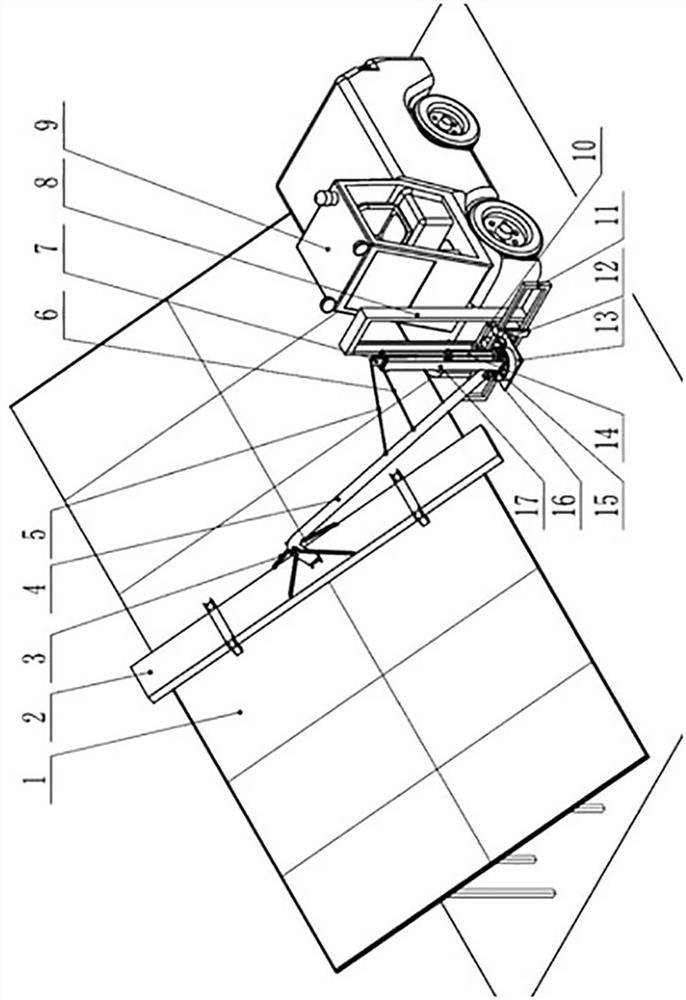

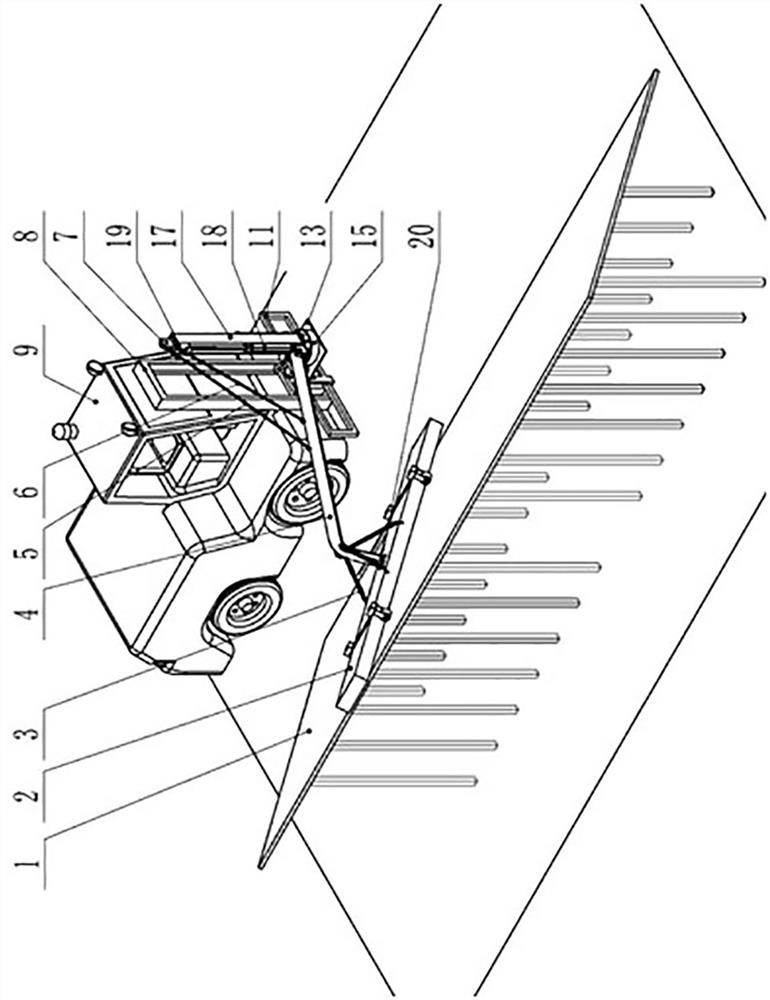

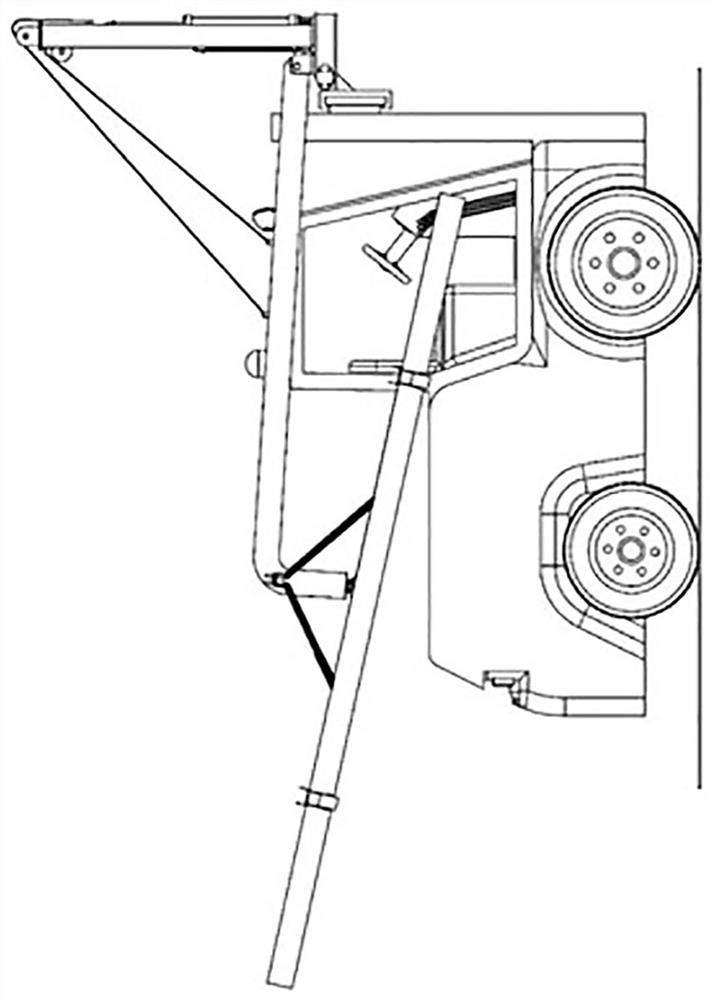

[0008] like Figure 1~Figure 4 As shown in the figure, the present invention is a high-efficiency dust removal equipment for solar photovoltaic panels, including a cleaning brush 2, a balance spring 3, a beam 4, a steel wire rope I5, a steel wire rope II6, a horizontal sliding table 13, a gas spring 14, a turntable 15, a hinge support 16, a pull Lifting cylinder 18, the front end of the vehicle body 9 is fixed with a vertical moving guide rail 8, and the vertical sliding table 10 is installed in the vertical moving guide rail 8; the horizontal moving guide rail 11 is fixed on the vertical sliding table 10, and the horizontal sliding table 13 is installed in In the horizontal moving guide rail 11; the turntable 15 is installed on the horizontal slide table 13, the rotating oil cylinder 12, the gas spring 14, the hinge support 16, the column 17 and the pull-up oil cylinder 18 are installed on the turntable 15; the pulley I7 is installed on the top of the column 17, and the pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com