Structure for dredging concrete mortar in construction steel pipes

A technology for concrete mortar and steel pipes, which is applied to cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., and can solve the problems of easy deviation from the actual position and large swing of the drill bit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

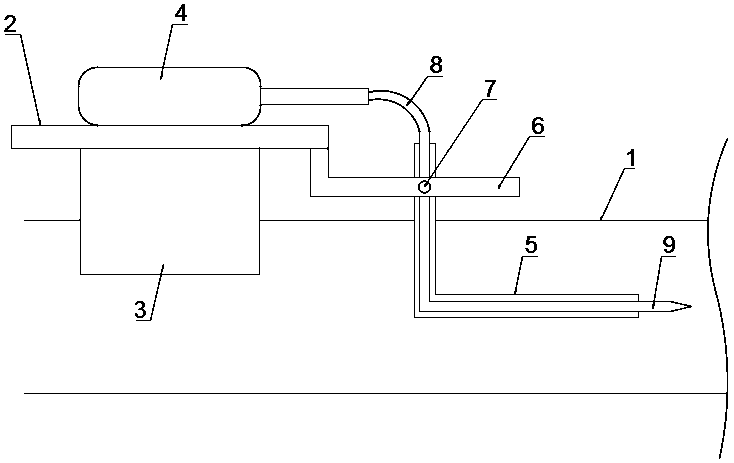

Embodiment 1

[0022] refer to figure 1 , Figure 4 , a concrete mortar dredging structure inside a building steel pipe, including a mounting plate 2 arranged on the upper side of the steel pipe 1, the lower side of the mounting plate 2 is provided with a fixing mechanism connected to the steel pipe 1, and the fixing mechanism includes two lower side walls connected to the mounting plate 2 Rotate the connected arc plate 3, the upper side wall of the mounting plate 2 is fixed with a telescopic rod 11, the driving end of the telescopic rod 11 is vertically fixed with a U-shaped plate 10, and the two ends of the U-shaped plate 10 extend through the mounting plate 2 to The lower side of the mounting plate 2 is in contact with the outer wall of the arc-shaped plate 3. After the mounting plate 2 is placed on the steel pipe 1, the driving end of the telescopic rod 11 is retracted, driving the U-shaped plate 10 to move downwards, passing through the U-shaped plate 10 two The contact between the end...

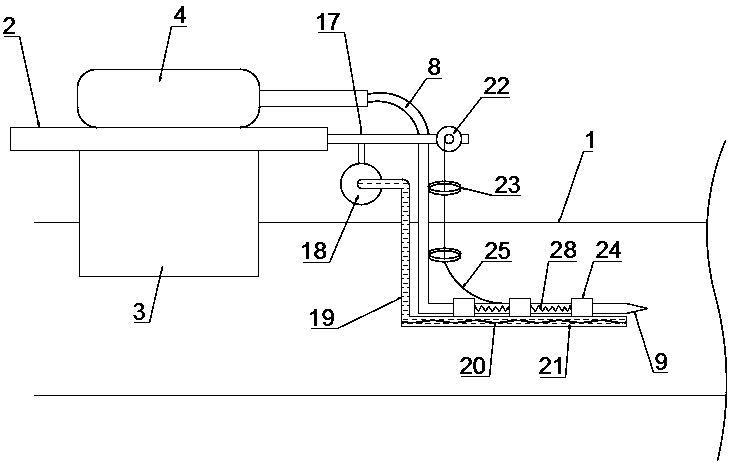

Embodiment 2

[0026] refer to figure 2 , Figure 4 , a concrete mortar dredging structure inside a building steel pipe, including a mounting plate 2 arranged on the upper side of the steel pipe 1, the lower side of the mounting plate 2 is provided with a fixing mechanism connected to the steel pipe 1, and the fixing mechanism includes two lower side walls connected to the mounting plate 2 Rotate the connected arc plate 3, the upper side wall of the mounting plate 2 is fixed with a telescopic rod 11, the driving end of the telescopic rod 11 is vertically fixed with a U-shaped plate 10, and the two ends of the U-shaped plate 10 extend through the mounting plate 2 to The lower side of the mounting plate 2 is in contact with the outer wall of the arc-shaped plate 3. After the mounting plate 2 is placed on the steel pipe 1, the driving end of the telescopic rod 11 is retracted, driving the U-shaped plate 10 to move downwards, passing through the U-shaped plate 10 two The contact between the en...

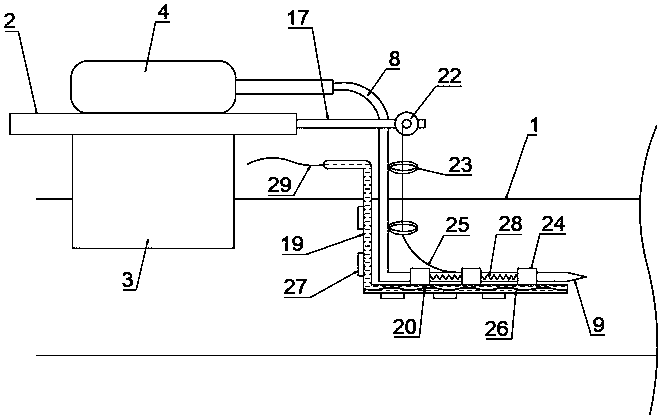

Embodiment 3

[0030] refer to image 3 , Figure 4 , a concrete mortar dredging structure inside a building steel pipe, including a mounting plate 2 arranged on the upper side of the steel pipe 1, the lower side of the mounting plate 2 is provided with a fixing mechanism connected to the steel pipe 1, and the fixing mechanism includes two lower side walls connected to the mounting plate 2 Rotate the connected arc plate 3, the upper side wall of the mounting plate 2 is fixed with a telescopic rod 11, the driving end of the telescopic rod 11 is vertically fixed with a U-shaped plate 10, and the two ends of the U-shaped plate 10 extend through the mounting plate 2 to The lower side of the mounting plate 2 is in contact with the outer wall of the arc-shaped plate 3. After the mounting plate 2 is placed on the steel pipe 1, the driving end of the telescopic rod 11 is retracted, driving the U-shaped plate 10 to move downwards, passing through the U-shaped plate 10 two The contact between the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com