Copper bar production process

A production process and technology for copper rods, applied in metal rolling and other directions, can solve the problems of unutilized heat and heat waste, and achieve the effects of improving utilization, improving combustion efficiency, and high combustion heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention discloses a copper rod production process, comprising the following steps:

[0031] 1) Copper melting process: use the copper plate preheating furnace to melt the copper plate 100 into molten copper, during which the high-temperature exhaust gas after combustion is returned to the nozzle, preheating the gas in the outer air guide pipe and the inner air guide pipe, and increasing the outer air guide pipe And the air pressure in the inner air guide pipe, the gas flowing out of the nozzle enters the preheating chamber of the combustion chamber of the copper plate preheating furnace to preheat the copper plate to be melted;

[0032] 2) Rod casting process: casting the molten copper on the surface of the core rod to generate a cast rod;

[0033] 3) Hot-rolling process: hot-rolling the cooled cast rod to generate a copper rod;

[0034] 4) Winding process: wind the above-mentioned copper rod into a circle.

Embodiment 2

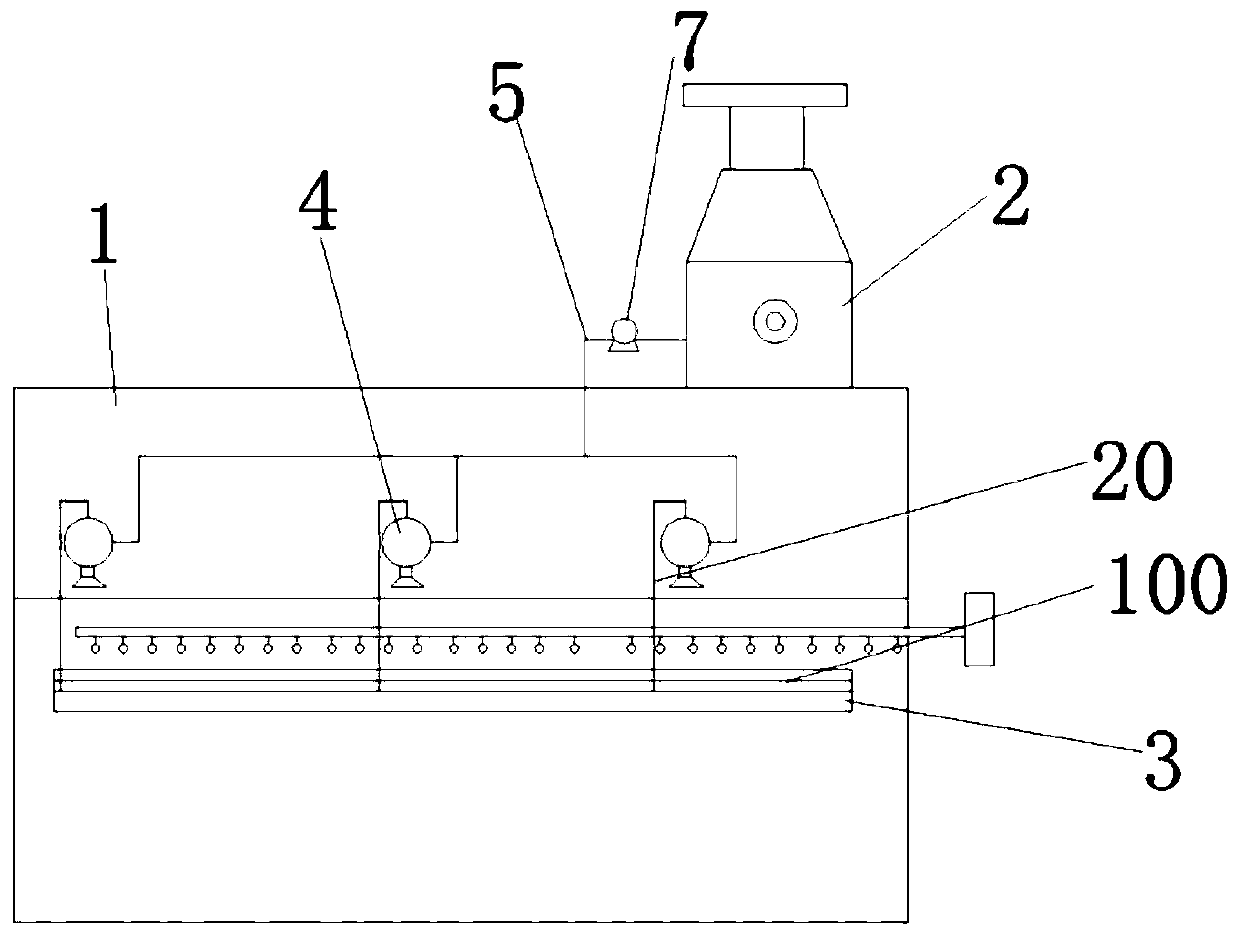

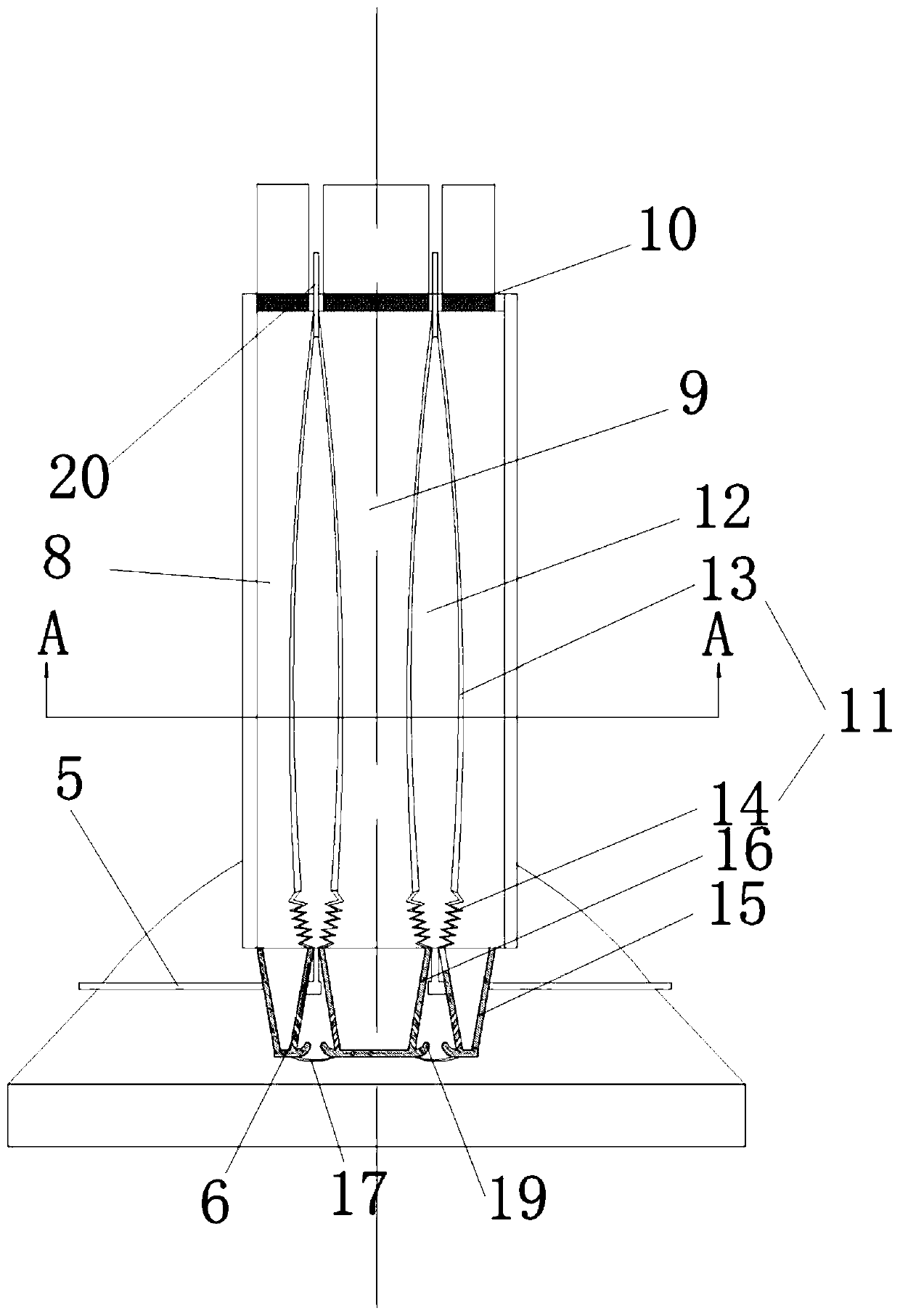

[0036] Such as figure 1 , figure 2 , image 3 and Figure 4 , the present invention also discloses a copper plate preheating furnace, comprising: a combustion chamber 1 and a smoke exhaust device 2 installed on the top of the combustion chamber; the bottom of the combustion chamber is equipped with a preheating chamber 3, the upper part of the preheating chamber A copper plate 100 is installed; a nozzle 4 is installed on the upper part of the combustion chamber, and the smoke exhaust device is connected to the nozzle through the return pipeline 5, and the nozzle is connected to the preheating chamber 6 through the intake pipeline 20, and the return pipeline is equipped with a pressurized pump 7;

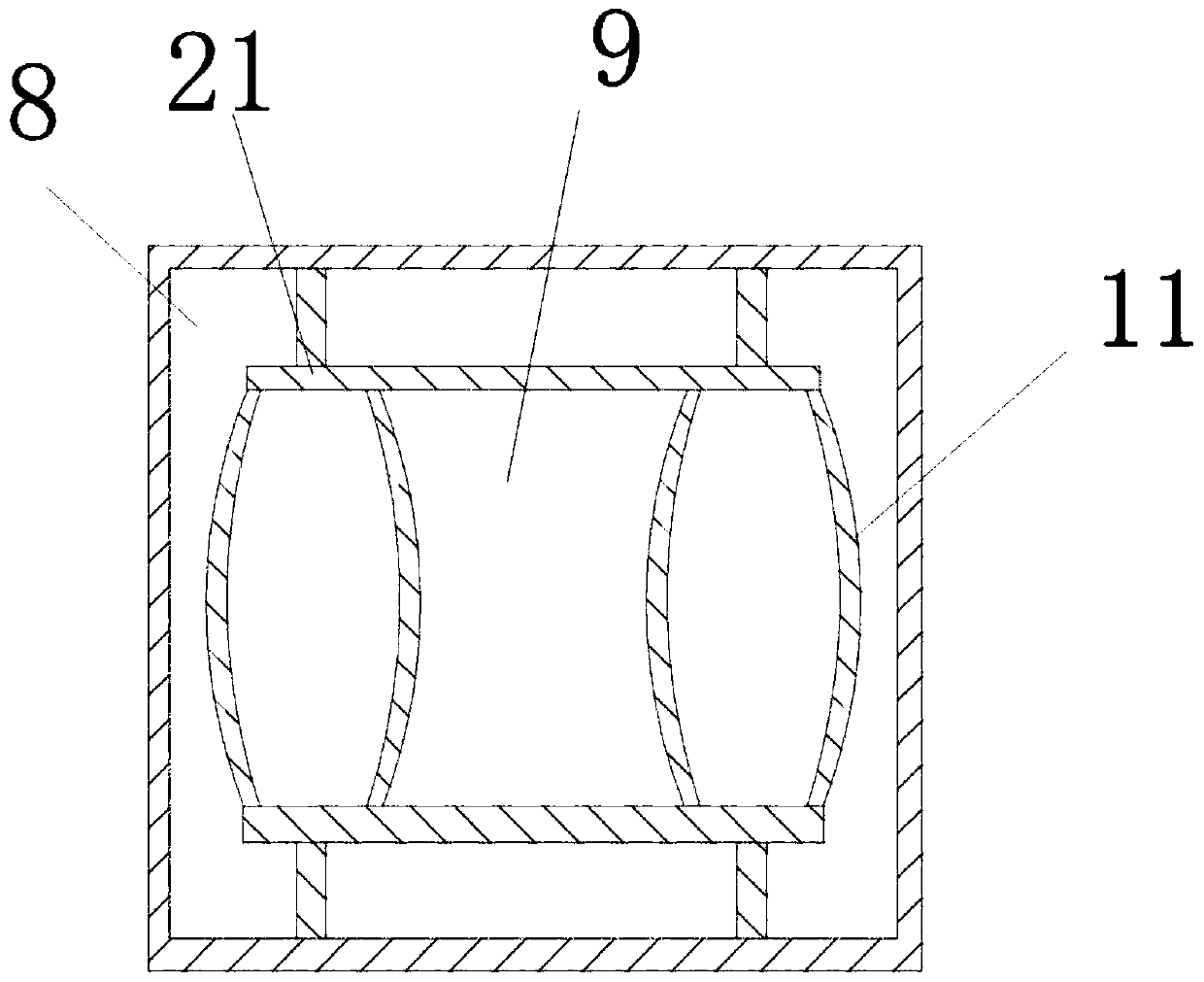

[0037] The nozzle includes an outer air guide pipe 8 with a combustible gas and an inner air guide pipe 9 with a combustion-supporting gas. The end of the outer air guide pipe and the inner air guide pipe near the intake side is equipped with a one-way valve 10. The one-way valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com