Production system of hoisting anchor rod and process thereof

A production system and technology for hanging bolts, which are applied in other manufacturing equipment/tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low processing efficiency, complicated operation, and cumbersome process, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

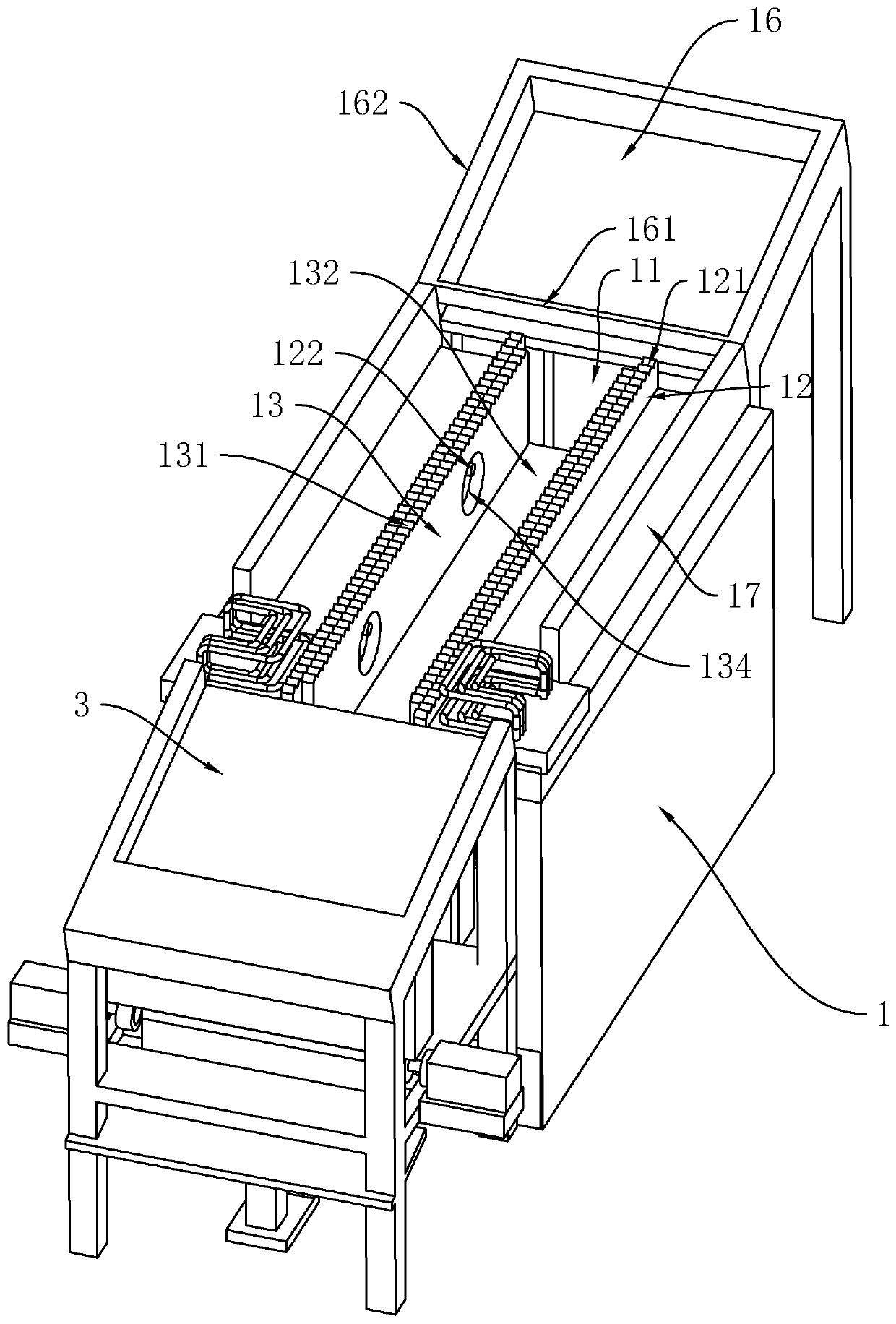

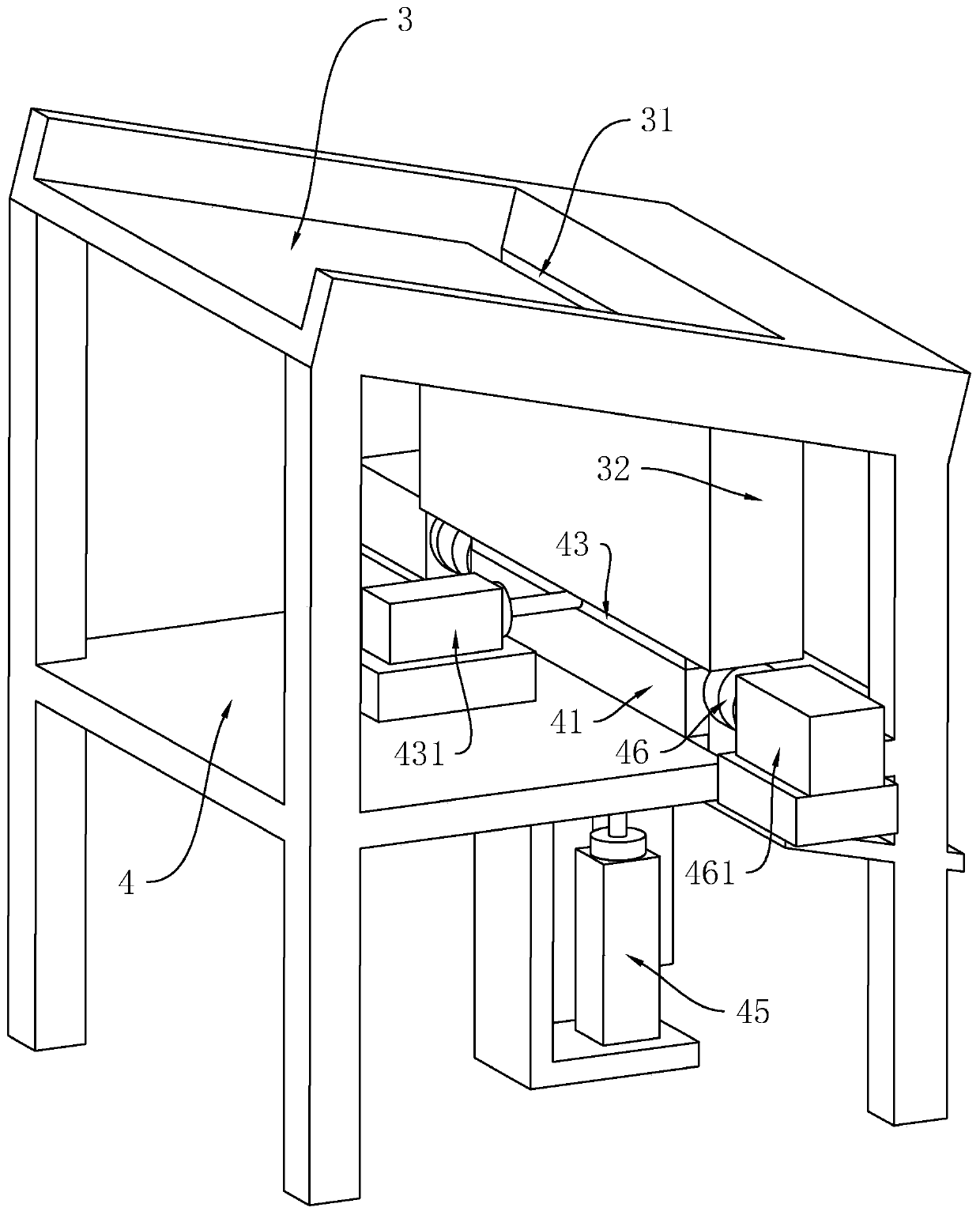

[0043] Embodiment one: refer to figure 1 , a production system for lifting anchor rods, including automatic feeding heating equipment and molding equipment.

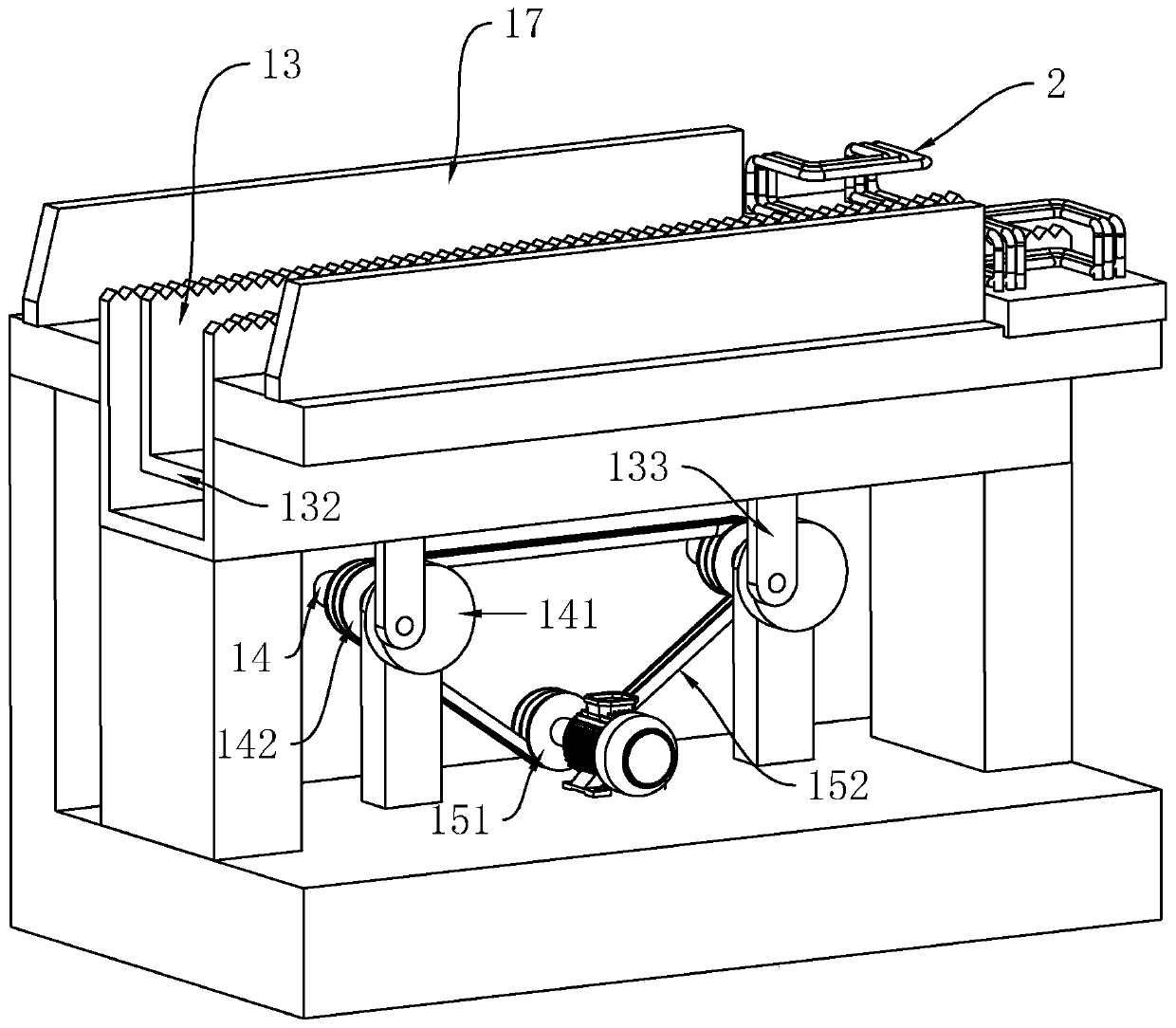

[0044] refer to figure 1 and figure 2 , the automatic heating device comprises a rectangular bottom frame 1, the middle part of the bottom frame 1 is provided with a long groove 11, the length direction of the long groove 11 is the same as that of the bottom frame 1, and the two sides of the bottom frame 1 corresponding to the long groove 11 are all vertical The support plate 12 is fixedly connected, and the length direction of the support plate 12 is the same as the length direction of the long groove 11. The upper sides of the two support plates 12 are evenly provided with corresponding tooth grooves 121 along the length direction of the support plate 12, and the long groove 11 Both sides of the feed plate 13 are vertically provided with the feed plate 13 whose length direction is the same as the length direction of...

Embodiment 2

[0053] Embodiment 2: a production process for a lifting anchor disclosed by the present invention, comprising the following steps:

[0054] Step 1, cut into sections, cut the long steel bar into several steel columns according to the same length;

[0055] Step 2, heating, transfer the steel column in sequence and heat the two ends of the steel column respectively;

[0056] Step 3, forming, fixing the middle part of the steel column, and making the two ends of the steel column respectively have the length of the heating section, and then simultaneously pressing the two ends of the steel column inward to form a disc-shaped end;

[0057] Step 4. Cooling. Take out the formed steel columns at both ends and cool them down.

[0058] The implementation principle of this embodiment is: when processing the anchor rod, both ends of the steel column need to be heated, and then extruded at the same time. The operation is simple, and the technical level of the workers is greatly reduced, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com