Welding method for cold-rolled 25# steel solid laser welding machine

A solid-state laser, welding method technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of welding seam quality defects, inability to obtain laser welding process combination parameters, increasing orders, etc. The effect of product manufacturing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0009] 1. Laser welding machine welds 25# steel,

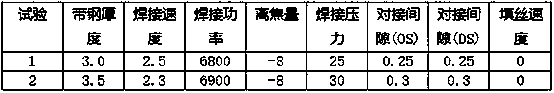

[0010] Export steel type (25#), thickness 3.0mm, imported steel type (25#), thickness 3.0mm, laser welding machine for welding, weld cupping test. After observing the shape of the weld seam and the appearance of the weld seam after cupping, it is concluded that in the absence of the weld seam preheating and annealing function device, the weld seam appears impenetrable or the material is brittle and causes cupping after welding. Cracked imagination.

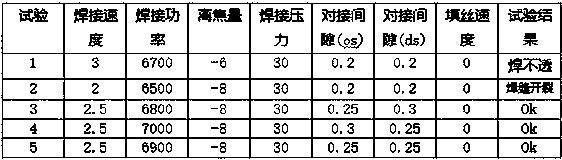

[0011] 2. By judging the quality of the weld, breaking through the limitations of the laser welding machine's own preheating and annealing functions, researching and adjusting the welding process parameters, and conducting a large number of welding experiments, the welding parameters are selected in the following table:

[0012]

[0013] According to the experimental results, the welding test 5 is selected as the optimal welding parameter (standard correction of the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com