End part finishing mechanism of circular pipe pile end plate

A technology for trimming mechanisms and circular tubes, which is applied to metal processing machinery parts, clamping, and supports, which can solve the problems of cumbersome operations and low processing efficiency, and achieve the effects of high mechanization, increased processing efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

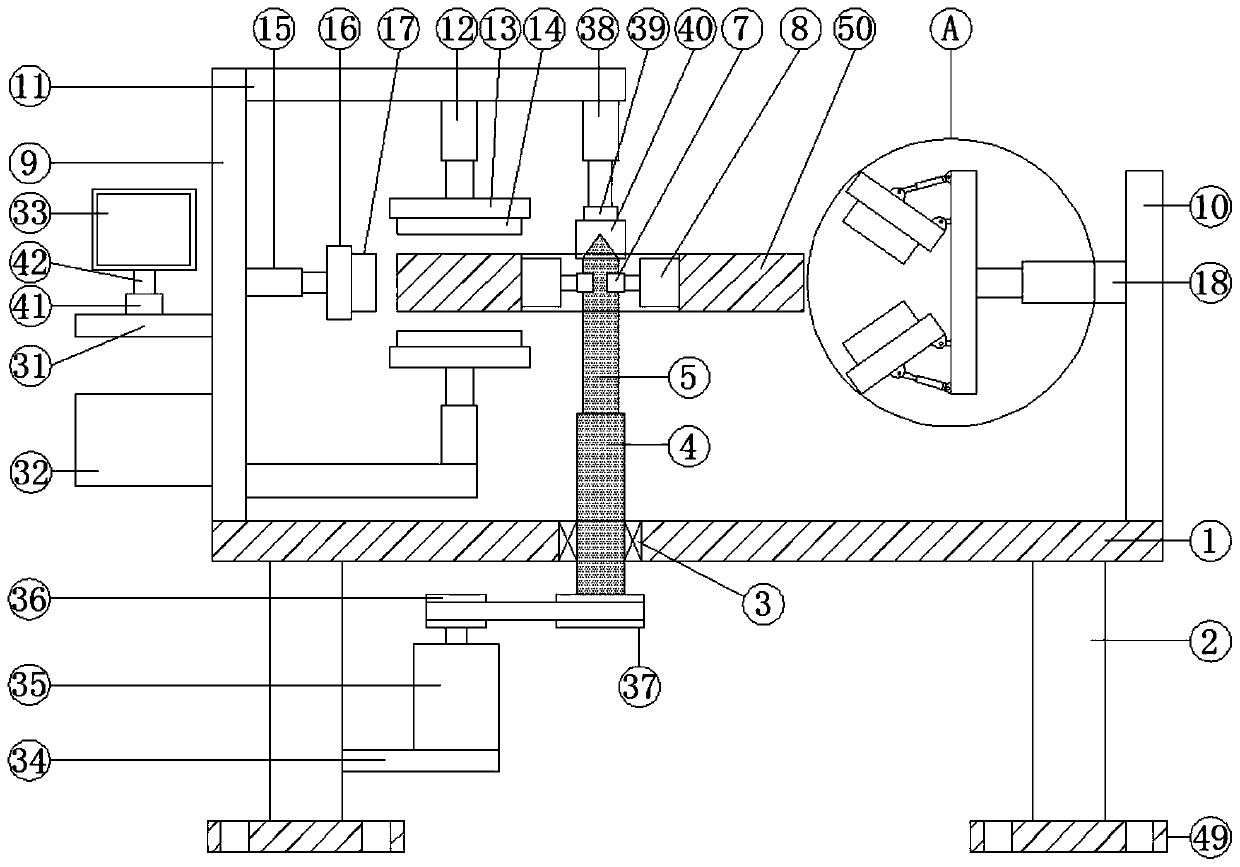

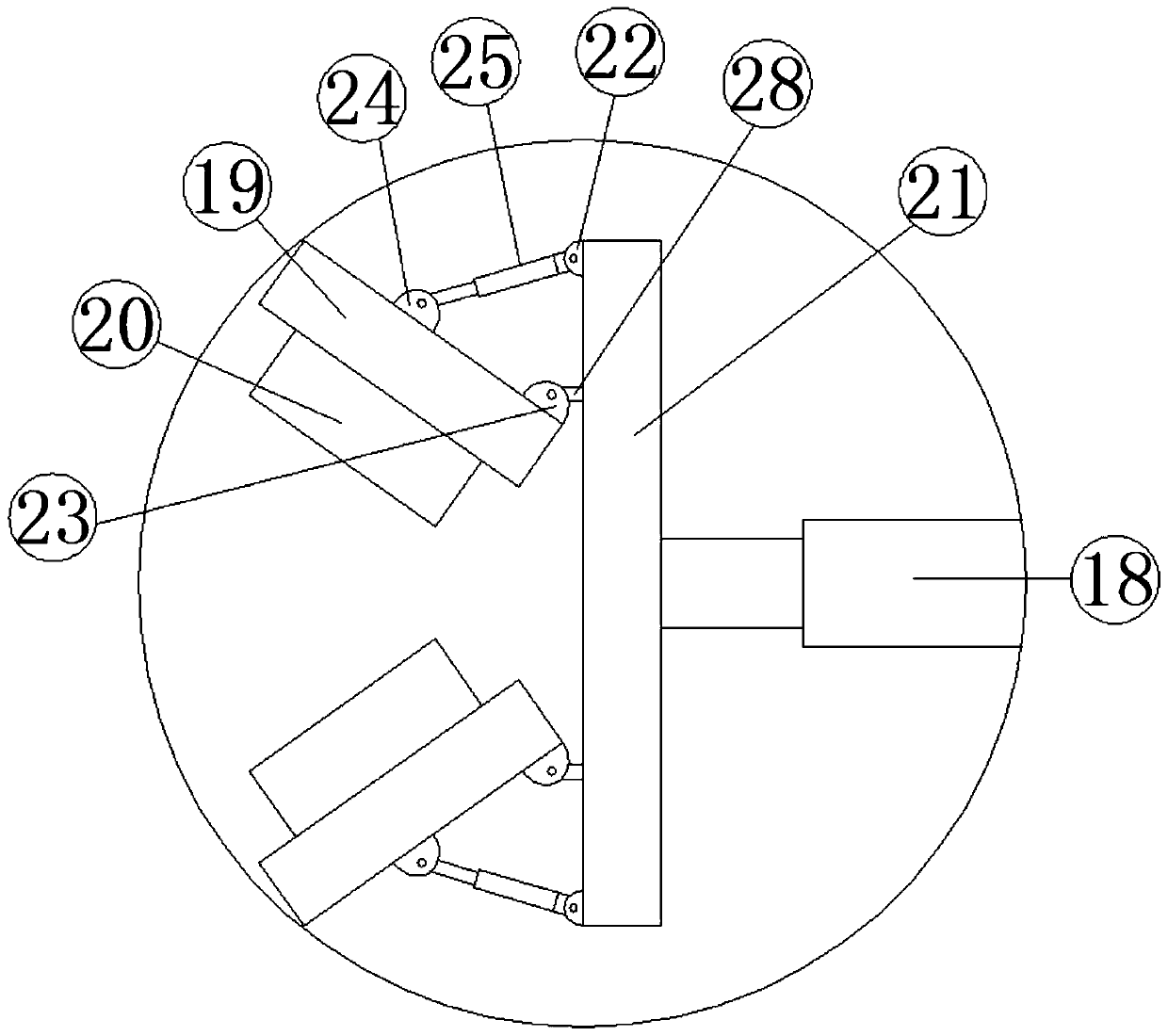

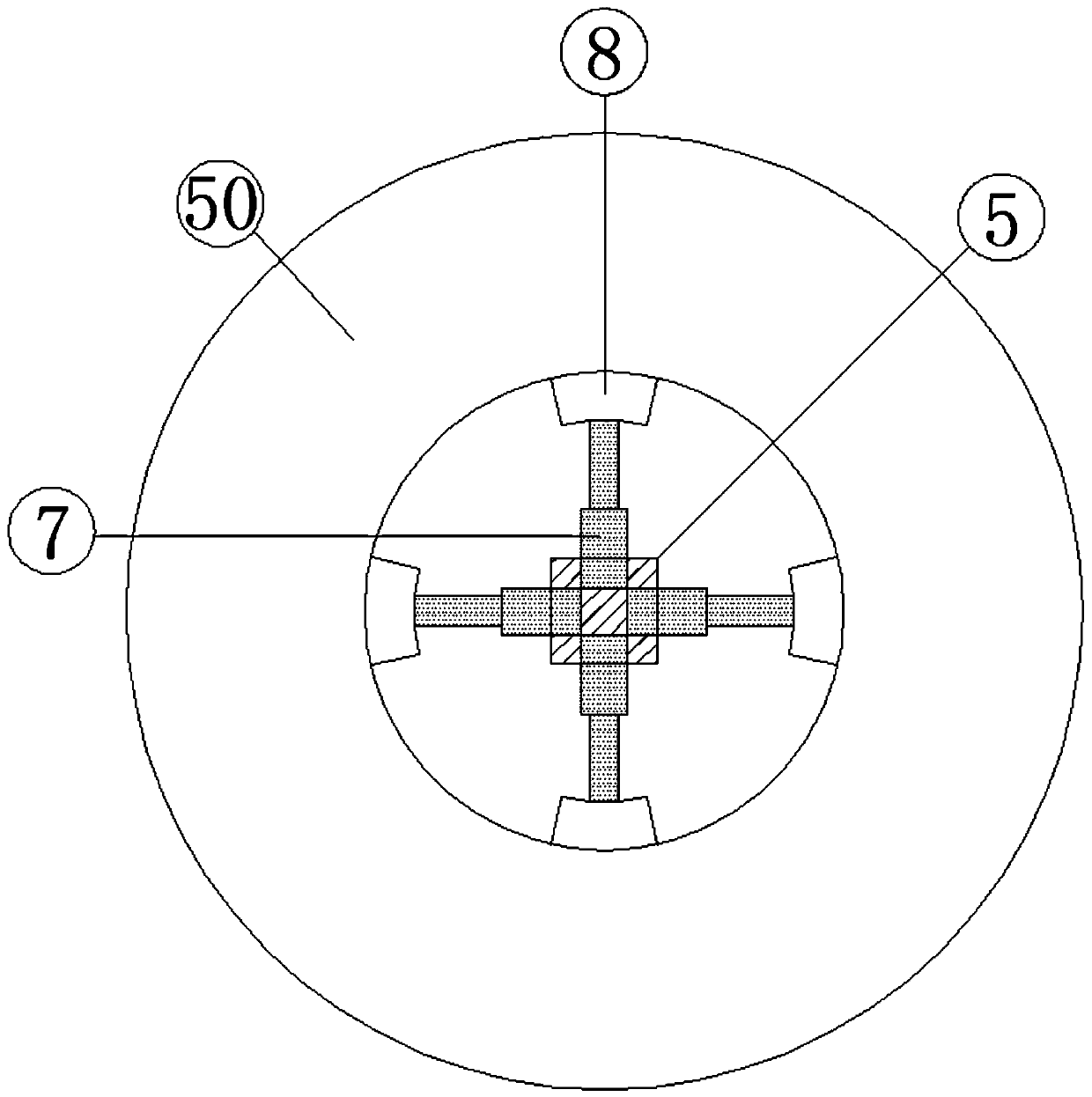

[0033] see Figure 1-8According to an embodiment of the present invention, an end trimming mechanism for a circular pipe pile end plate includes a workbench 1, and support columns 2 are fixed under the four corners of the workbench 1, and the workbench 1 is provided with There are a fixing device, an end face grinding device, an edge polishing device and a chamfering device, the fixing device includes a first bearing 3, a transmission shaft 4 is fixed inside the first bearing 3, and a driving device is provided at the lower end of the transmission shaft 4 , the upper end of the transmission shaft 4 is fixed with a square steel column 5, and the four sides of the square steel column 5 close to the upper end are provided with installation holes 6, and the first hydraulic cylinder 7 is fixed in the installation holes 6. One end of the expansion rod of the first hydraulic cylinder 7 is fixedly provided with an arc-shaped inner support block 8, a limit device is provided above the ...

Embodiment 2

[0036] see figure 1 , for the driving device, the driving device includes a second mounting plate 34, a motor 35, a first pulley 36, a second pulley 37 and a V-belt, and a second installation is fixed between the support columns 2 on one side. plate 34, the second mounting plate 34 is fixed with a motor 35, the outer wall of the rotating shaft of the motor 35 is fixed with a first pulley 36, and the outer wall of the lower end of the transmission shaft 4 is fixed with a second pulley 37, so The first pulley 36 and the second pulley 37 are driven by a V-belt.

[0037] Through the above solution of the present invention, the motor 35 can be used to drive the transmission shaft 4 to rotate through the V-belt, thereby driving the square steel column 5 and the pipe pile end plate blank ring 50 to rotate.

Embodiment 3

[0039] see figure 1 , 4 and 5, for the limiting device, the limiting device includes a fifth hydraulic cylinder 38, the fifth hydraulic cylinder 38 is fixed under the first fixing plate 11 at the upper end of the first side plate 9, and the The fifth hydraulic cylinder 38 is coaxial with the transmission shaft 4, the outer wall of the lower end of the piston rod of the fifth hydraulic cylinder 38 is fixedly provided with a third bearing 39, and the third bearing 39 is fixedly provided with a card seat 40, so The lower end of the card seat 40 is provided with a rectangular pyramid-shaped groove 43, and the upper end of the square steel column 5 is fixed with a rectangular pyramid-shaped protrusion 44, and the groove 43 matches the protrusion 44. Both the hydraulic pump and the electromagnetic reversing valve of the fifth hydraulic cylinder 38 are electrically connected to the PLC controller 32 .

[0040] Through the above scheme of the present invention, the protrusion 44 on ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap