Optical mold, explosion-proof membrane, manufacturing method thereof, back cover and electronic equipment

A production method and technology of explosion-proof film, applied in optical components, household appliances, other household appliances, etc., can solve the problems of complex injection molding process, waste of manufacturing process time, optical product structure and shape limitations, etc., and achieve unique visual and tactile effects. , low manufacturing cost, to achieve the effect of differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

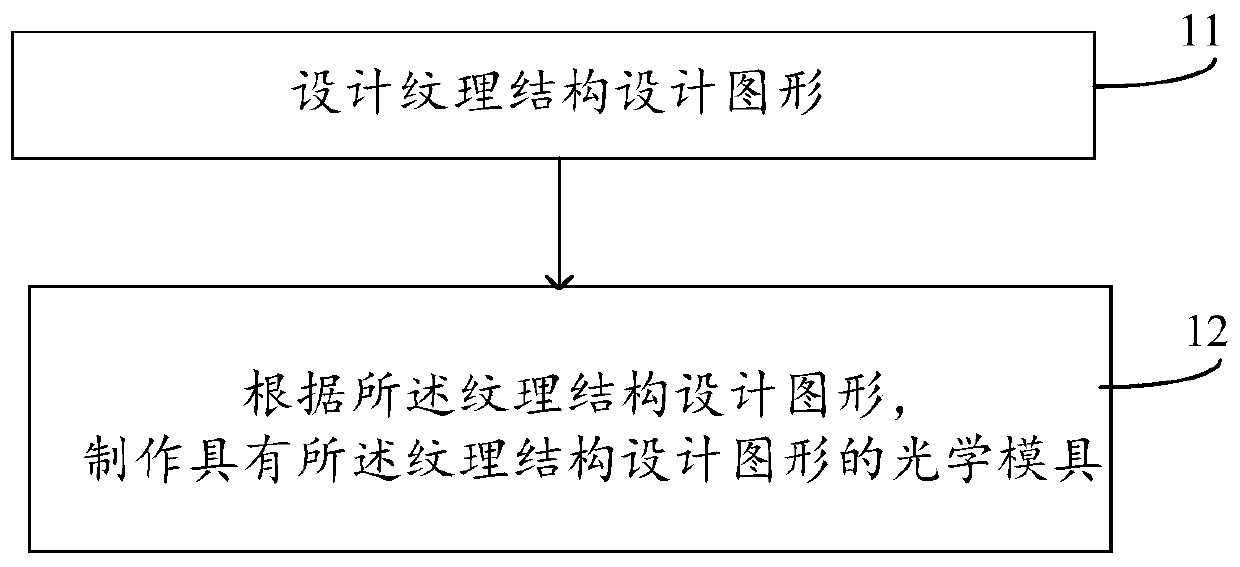

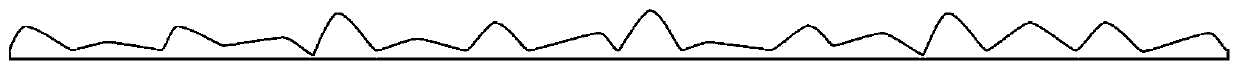

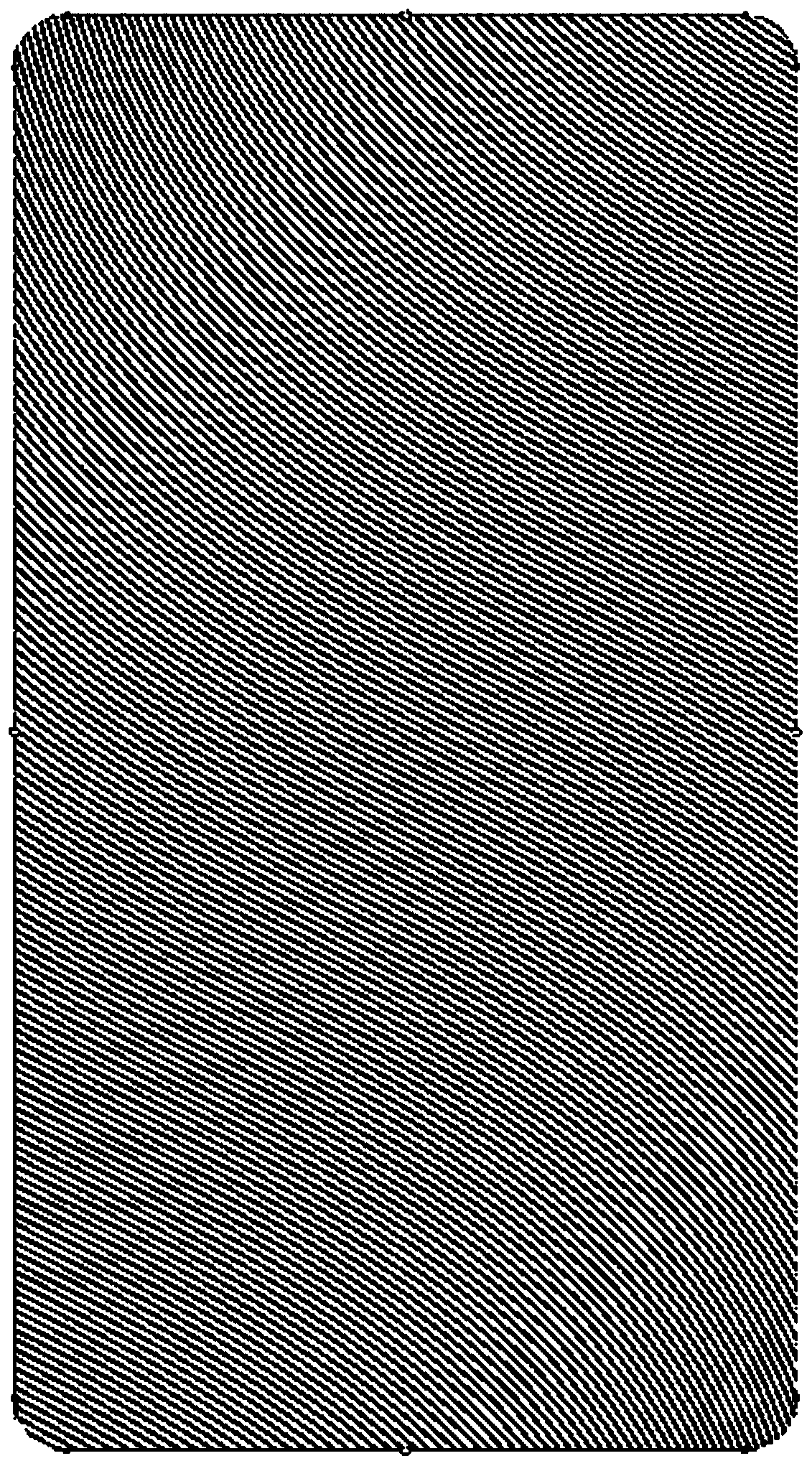

Method used

Image

Examples

Embodiment Construction

[0019] The term "comprising" and any variations thereof in the description and claims of this application are intended to cover a non-exclusive inclusion, for example, a process, method, system, product, or device comprising a series of steps or units is not necessarily limited to the explicit instead of those steps or elements explicitly listed, other steps or elements not explicitly listed or inherent to the process, method, product or apparatus may be included. In addition, the use of "and / or" in the description and claims means at least one of the connected objects, such as A and / or B, means that there are three situations including A alone, B alone, and both A and B.

[0020] In the embodiments of the present invention, words such as "exemplary" or "for example" are used as examples, illustrations or illustrations. Any embodiment or design solution described as "exemplary" or "for example" in the embodiments of the present invention shall not be construed as being more pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com