A preparation method of composite material lifting lug and composite material lifting lug

A technology of composite materials and lifting lugs, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of difficult opening of ear holes, low structural strength of ear holes, etc., achieve the effect of precise position and wide application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

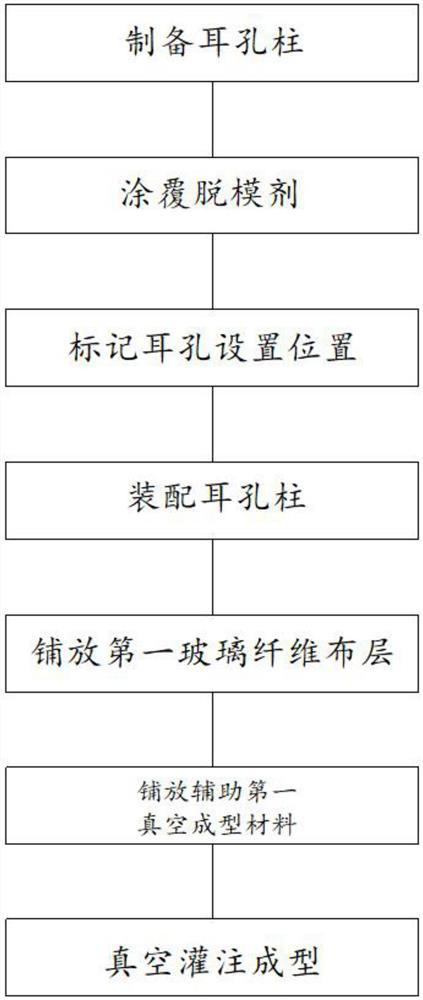

[0058] See figure 1 , the present invention provides a kind of preparation method of composite material lifting lug, described method comprises the following steps:

[0059] Prepare the ear hole post: the cross-sectional shape of the ear hole post is adapted to the shape of the ear hole of the composite material lifting ear; the length of the ear hole post is 10 to 30 mm greater than the depth of the ear hole;

[0060] Coating the release agent: apply the release agent 1 to 2 times in the cavity of the clean vacuum into the mold;

[0061] Marking the setting position of the ear hole: marking the setting position of the ear hole in the mold cavity;

[0062] Assembling the ear hole post: bonding the bottom surface of the ear hole post to the marked position of the ear hole; coating the exposed surface of the ear hole post with the release agent 1 to 2 times;

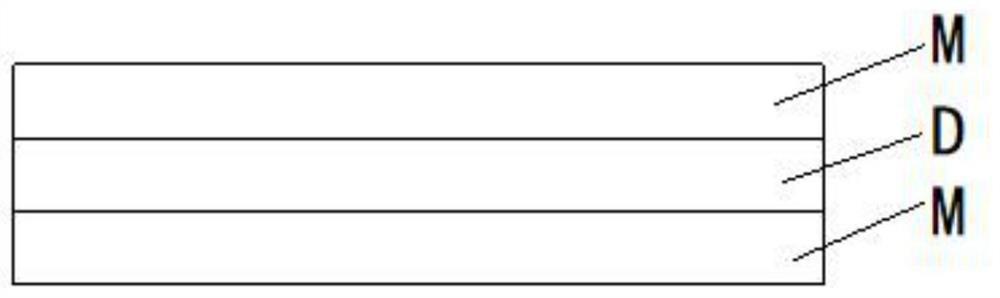

[0063] Laying the first glass fiber cloth layer: laying the glass fiber cloth layer in the inner cavity of the mold ca...

Embodiment 2

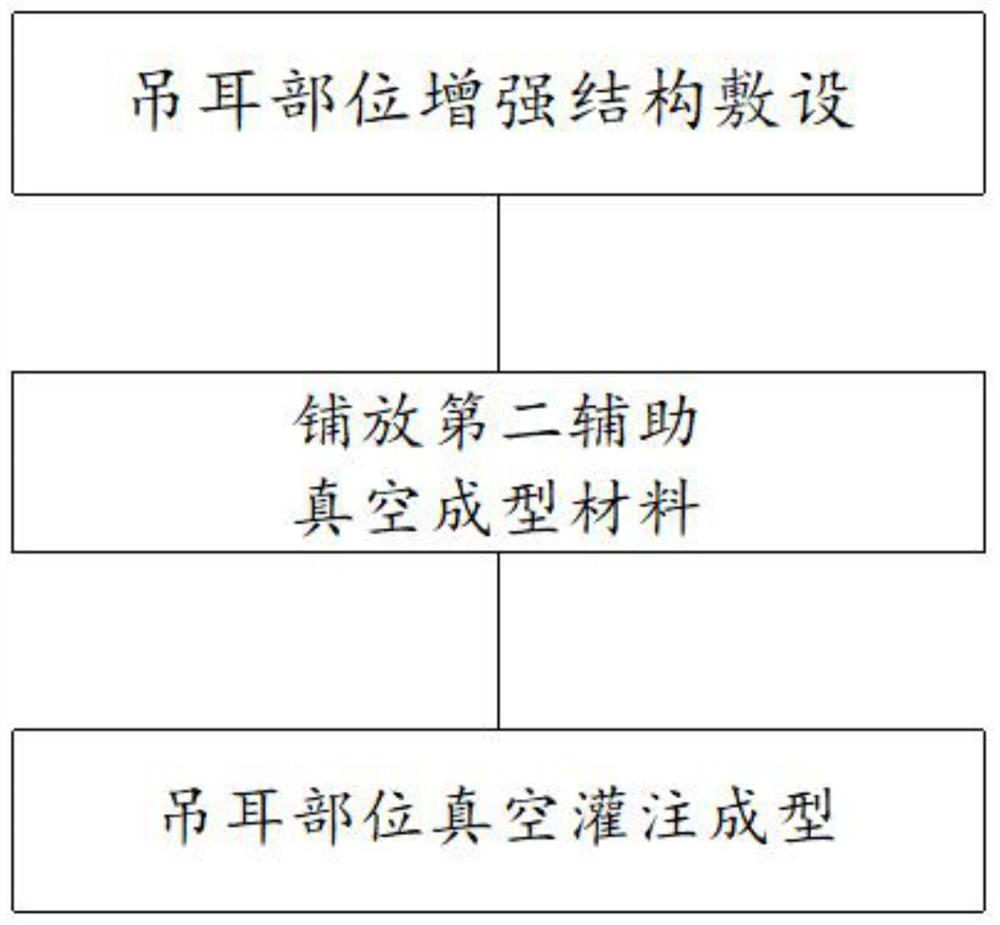

[0080] Such as figure 2 As shown, on the basis of Embodiment 1, this embodiment also includes the following steps:

[0081] Laying of the reinforced structure at the lug part: laying a second glass fiber cloth layer at the position where the ear hole of the injection molded product is set;

[0082] Laying the second auxiliary vacuum forming material: laying the second release cloth, the second guide net, the second glue injection pipe, the second glue suction pipe and the second vacuum film sequentially above the second glass fiber cloth layer; The second glue injection pipes are equidistantly arranged above the second guide net; the second glue suction tube is arranged at the edge of the second guide net; the second vacuum film is used to The laying position of the second glass fiber cloth layer is sealed;

[0083] Vacuum infusion molding at the hanger part: introduce injection molding raw materials into the second glass fiber cloth layer laying part through the second inj...

Embodiment 3

[0089] Such as Figure 4 and Figure 5 As shown, this embodiment provides a composite material lifting lug, which is made by the above method. The structure of the lifting lug includes: an ear seat 100 formed by vacuum drainage injection molding and a through hole 110 arranged on the ear seat 100 The ear base 100 includes: a body 101 and a connecting portion 102; the through hole 110 is disposed on the body 101; the connecting portion 102 is integrally connected with the body 101.

[0090] Preferably, in one of the preferred technical solutions of the present application, the body and the connection part are integrally formed by vacuum introduction and injection molding. made as Figure 6 As shown, the ear hole post 111 is inserted in the through hole, and the ear hole post 111 needs to be removed before the finished product is obtained.

[0091] Preferably, as Figure 4 to Figure 7As shown, in one of the preferred technical solutions of the present application, the body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com