Method for positioning by using laser three-dimensional projection in hull construction

A laser three-dimensional and laser projector technology, which is applied in the field of laser three-dimensional projection positioning and laser three-dimensional projection positioning structure, can solve the problems of low efficiency of positioning and marking, large human influence, and cumbersome tooling, so as to reduce waste of resources and manpower, reduce Human influence, the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

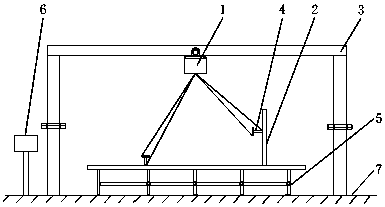

[0017] Projector fixed gantry 3 is set on the ground 7, below the gantry is the hull subsection structure 2, and laser projector 1 is fixed on the fixed gantry top, and the T-shaped profile profile 4 projected by the projector of the laser projector is irradiated on both sides. On the surface of the side segment structure, the segment structure is arranged on the segment structure tire frame 5, and a projector software system 6 is fixed by a bracket on the bottom surface of one side of the fixed door frame.

[0018] Describe the concrete implementation scheme that the present invention uses laser three-dimensional projection positioning T profile structure position on the hull section below in conjunction with technical scheme, its implementation steps are as follows:

[0019] 1) Hull structure model processing: Simplify the 3D data model of the hull segment and T-shaped structure, eliminate the model data irrelevant to the structure positioning projection, keep only the points...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com