Device and method for denitrifying sludge anaerobic digestion liquid

An anaerobic digestion and sludge technology, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of low overall treatment efficiency, reduction of pollutant operating load, and difficult control of nitrification and denitrification conditions. , to achieve the effect of increasing pollutant treatment load, high pollutant treatment load, and improving pool capacity utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

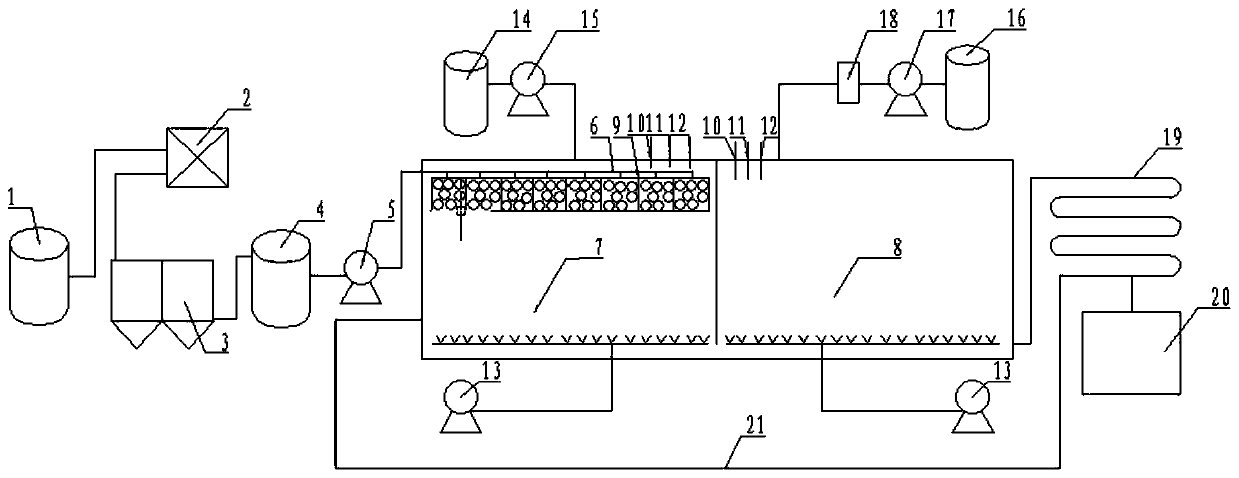

[0035] Such as figure 1As shown, a device for denitrification of sludge anaerobic digestion liquid includes a reaction tank, and the reaction tank is divided into a first reaction zone 7 and a second reaction zone 8 by a partition, and the first reaction zone 7 and the second reaction zone 8 The bottom is connected; the liquid surface of the first reaction zone 7 is provided with a stuffing cage 9; the top of the stuffing cage 9 is provided with a water distribution branch pipe 6; The pipeline of the liquid storage tank 14 is provided with a lye dosing pump 15; the bottom of the first reaction zone 7 is provided with an aeration branch pipe and is connected with a blower 13; the second reaction zone 8 is connected with a carbon source storage tank 16, and the carbon source storage A carbon source dosing pump 17 and a filter 18 are arranged sequentially on the pipeline from the tank 16 to the second reaction zone 8 ; the bottom of the second reaction zone 8 is provided with an ...

Embodiment 2

[0041] A method for denitrification of sludge anaerobic digestion liquid, using the device in embodiment 1 to process sludge anaerobic digestion liquid, comprising the following steps:

[0042] S1. The sludge anaerobic digestion liquid stored in the raw water pool 1 (the sludge press filter liquid produced after the high-temperature anaerobic digestion sludge of the municipal sludge disposal plant is tempered and dehydrated by the plate and frame, the water quality is NH 3 -N concentration is 2000mg / L, C / N ratio is 1, alkalinity is 2500mg / L, which belongs to waste water with high ammonia nitrogen, low C / N ratio, and low alkalinity), and the temperature is 50°C, SS is 1000mg / L, after cooling by the cooling tower 2 and removing impurities by the air flotation machine 3, it enters the pretreatment pool 4, the water temperature in the pool is 38°C, and the SS content is 300mg / L. Use the water inlet pump 5 to spray the sludge anaerobic digestion solution in the pretreatment tank 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap